Soldering device for forming electrical soldering point in magnetic disc driver

A disk drive, welding device technology, applied in the direction of tin feeding device, welding equipment, metal processing, etc., can solve the problems of laser beam energy increase, high energy consumption, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

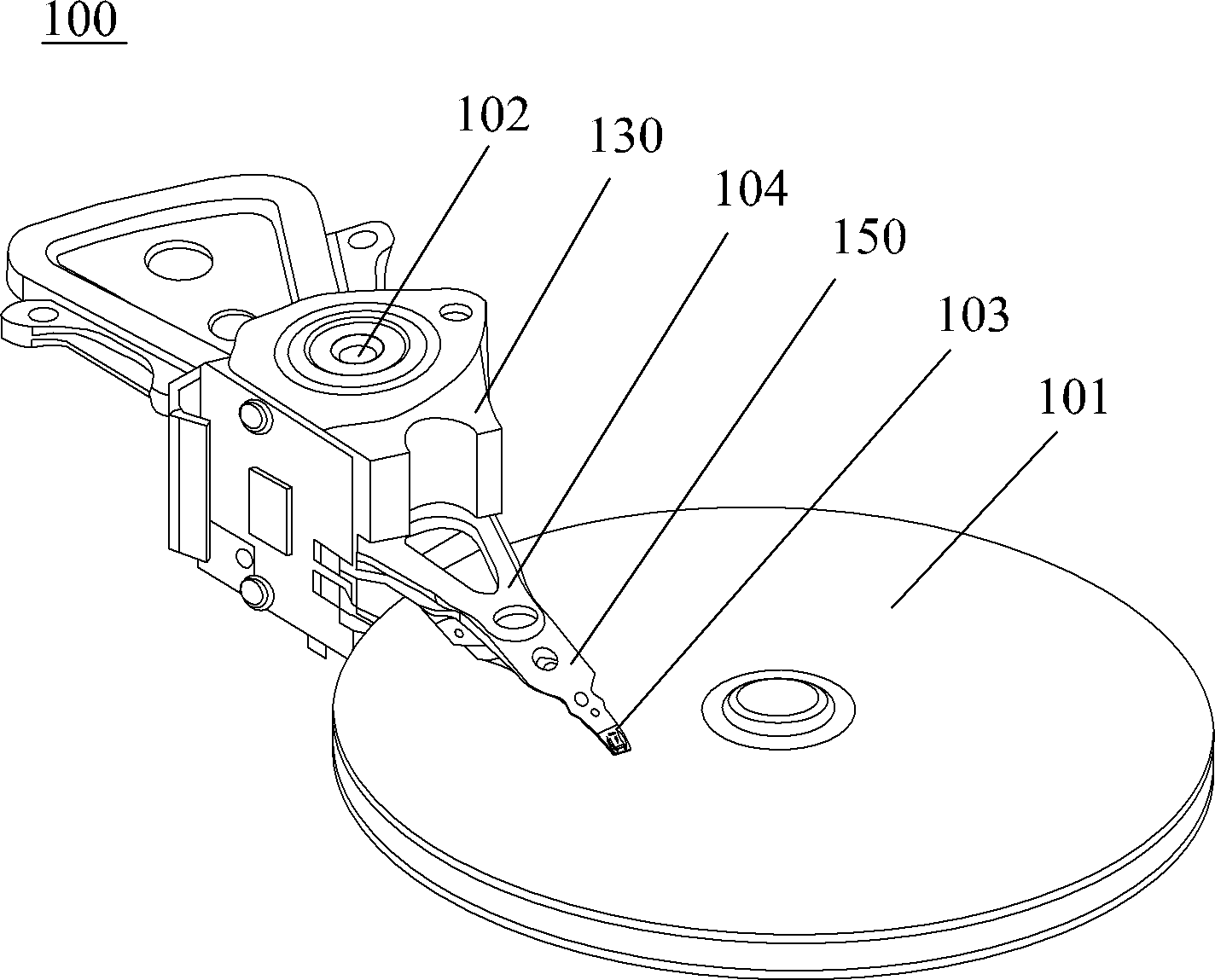

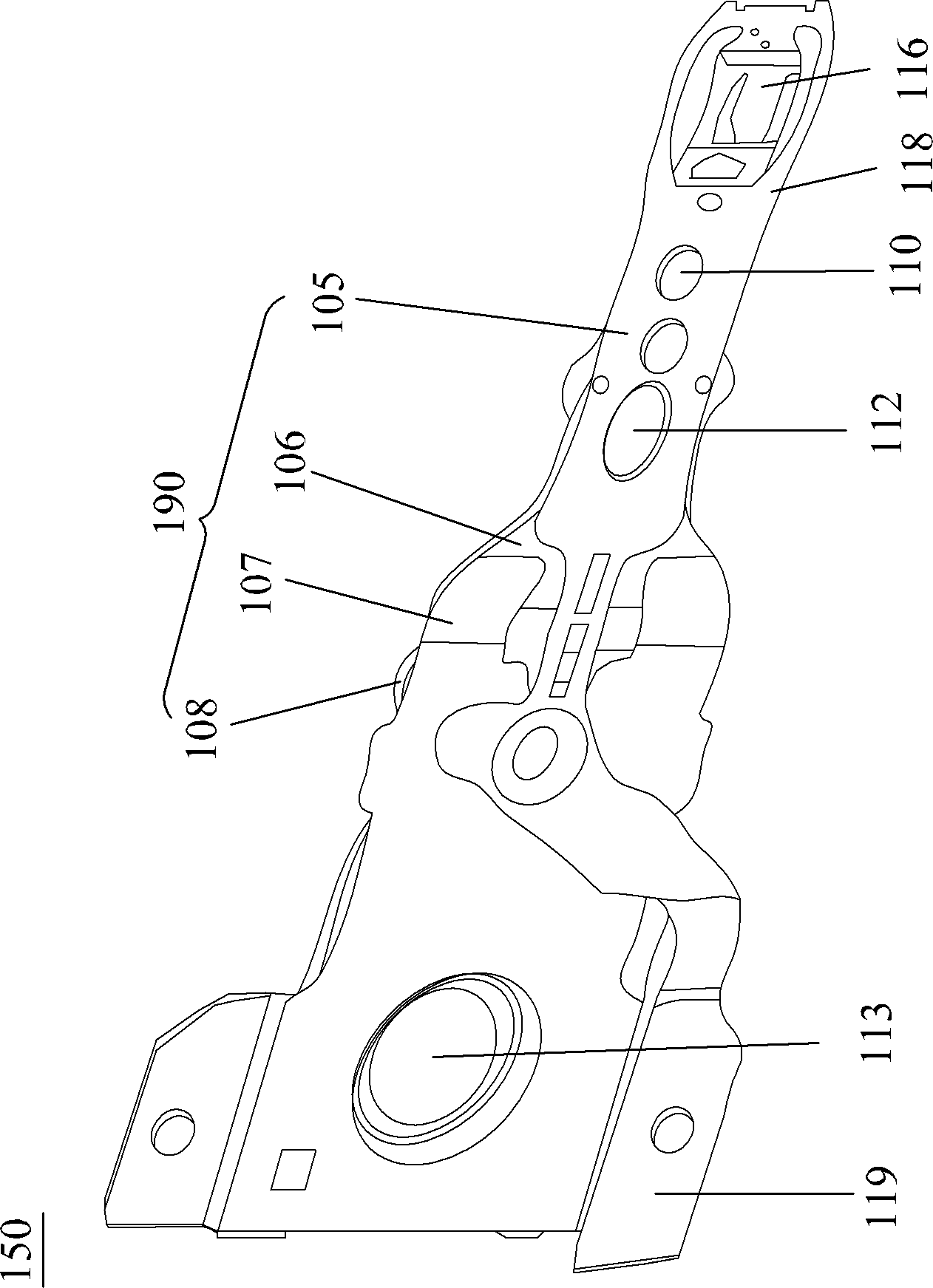

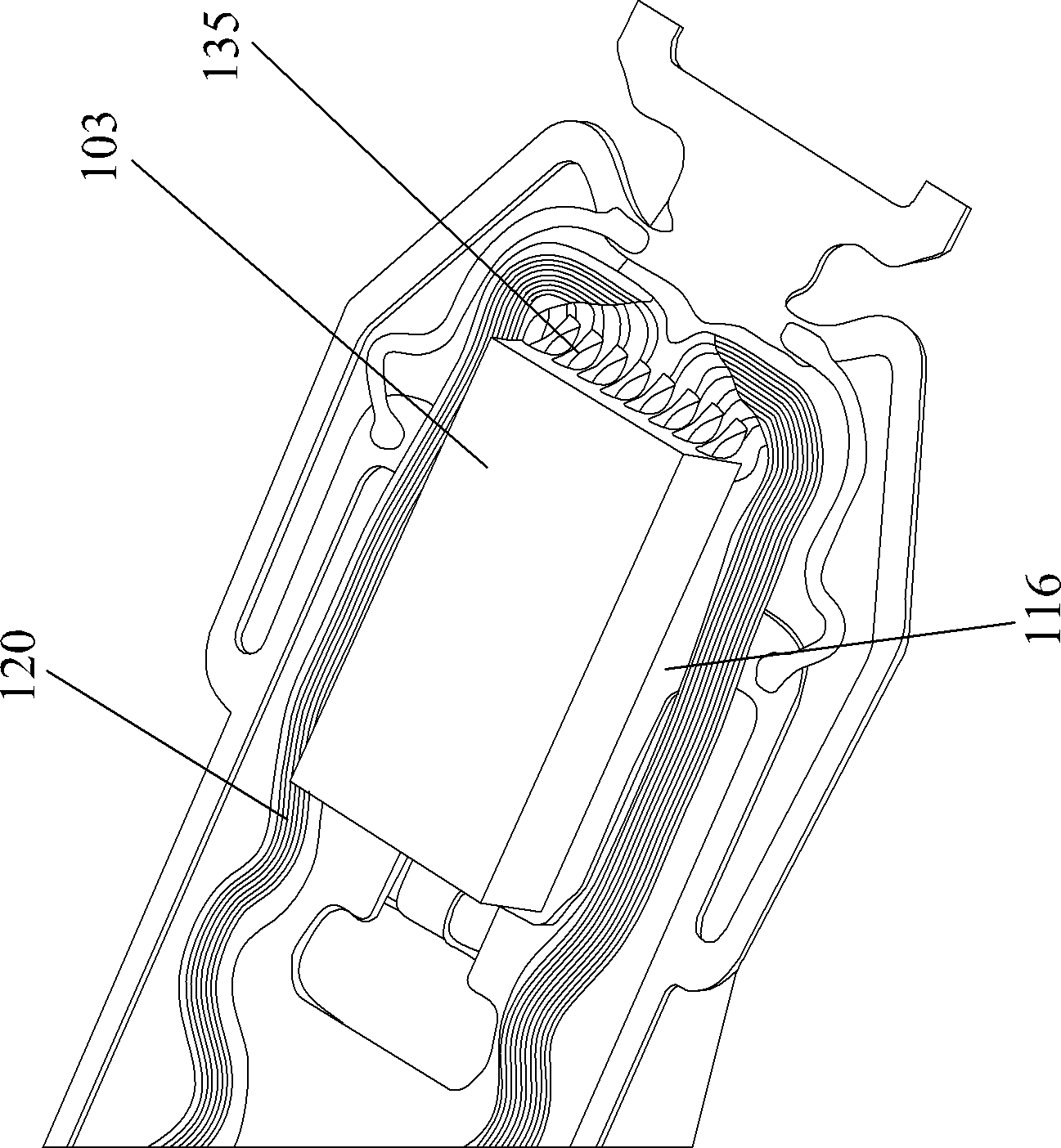

[0048] Several different preferred embodiments of the present invention will now be described with reference to the accompanying drawings, wherein like reference numerals in different drawings represent like parts. As mentioned above, the essence of the present invention is to provide a soldering device for forming an electrical solder joint in a hard disk drive, the soldering tip device has at least two separate movable shells, so that the size of the soldering tip can control for easy welding.

[0049] refer to Figure 4 , An embodiment of the soldering device 2 of the present invention includes a tip device 20 , a drive device 21 for driving the tip device 20 , a solder ball supply device 22 , a compressed gas supply device 23 and a laser generator 24 . Specifically, the welding tip device 20 has several separate movable shells, so that the size of the welding tip can be adjusted, and the driving device 21 is used to control the movement of the shell of the welding tip dev...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com