A fully automatic mobile articulated mine stone cutter

A mobile and articulated technology, applied in the field of mining stone cutters, can solve the problems of low cutting efficiency and waste, and achieve the effect of easy command and operation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

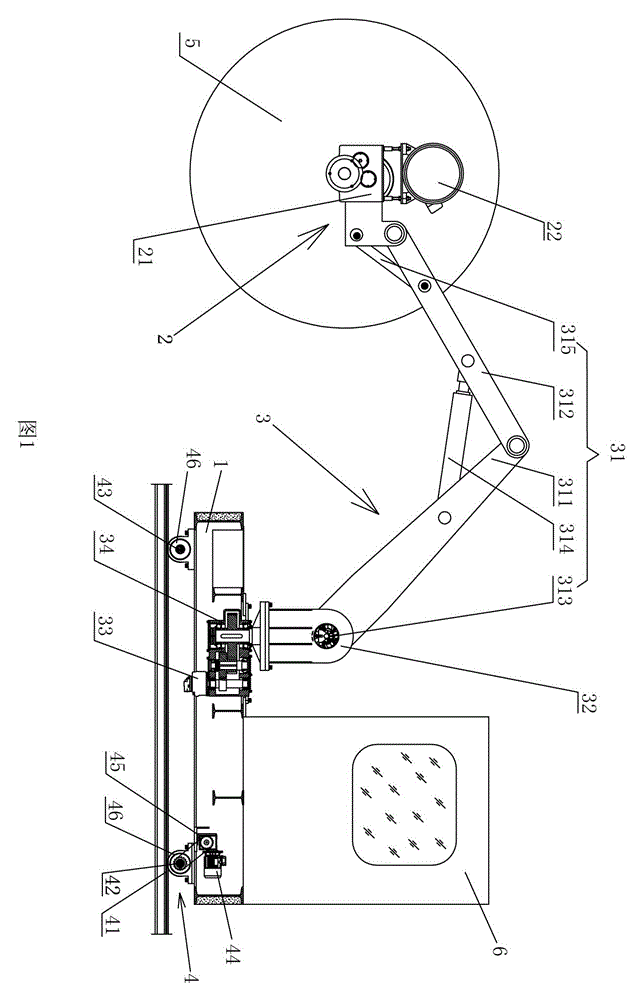

[0025] Refer to attached figure 1 . A fully automatic mobile articulated rock cutter, comprising a base 1, a cutting head 2, an operating room 6, a transmission support mechanism 3 for driving the rotation of the cutting head 2, and a walking mechanism 4 for moving the base, the transmission support One end of the mechanism 3 is installed on the base 1 and can rotate around a vertical axis of the plane defined by the base 1. The other end of the transmission support mechanism 3 is rotatably connected with the cutting head 2, which is installed on the cutting head 2. There is a cutting blade 5 for cutting ore, and the traveling mechanism 4 is installed on the bottom of the base 1 . The operating room 6 is fixed on the base 1 .

[0026] Refer to attached figure 1 . The transmission support mechanism 3 includes a manipulator 31, a rotating base 32, and a rotating base rotating hydraulic motor 33 for driving the rotating base 32 to rotate. The bottom of the rotating base 32 is...

Embodiment 2

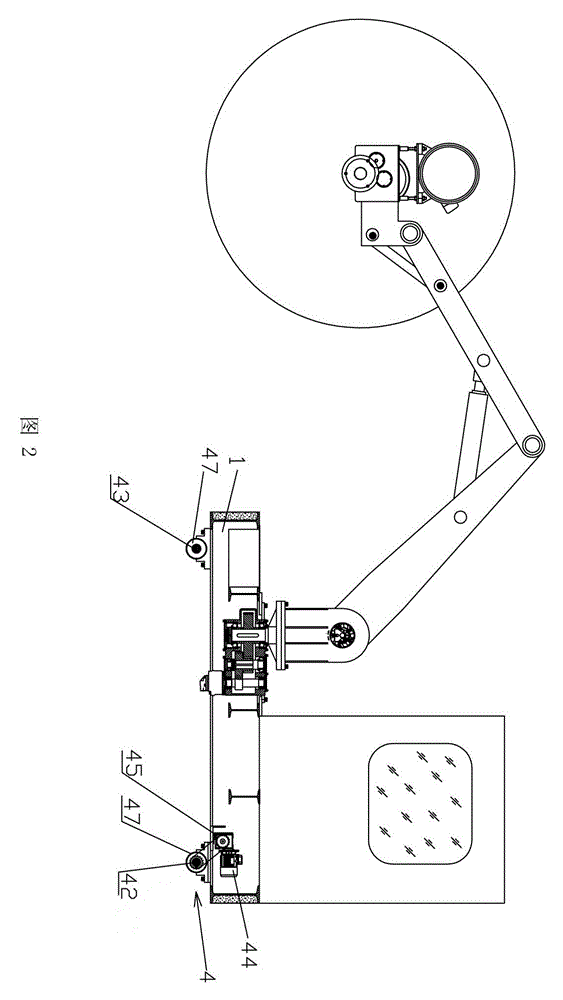

[0031] Refer to attached figure 2 . The embodiment of this embodiment is basically the same as that of Embodiment 1, the difference is that the traveling mechanism 4 includes a moving main shaft 42 and a moving auxiliary shaft 43 respectively installed on the rear bottom of the base 1 and the front bottom of the base 1 and used for Drive the drive motor 44 that moves the main shaft to rotate, the drive motor 44 is connected to the mobile main shaft 42 through a speed reducer 45, and the two ends of the mobile main shaft 42 and the mobile sub-shaft 43 are respectively equipped with wheels 47 for moving the base 1 .

Embodiment 3

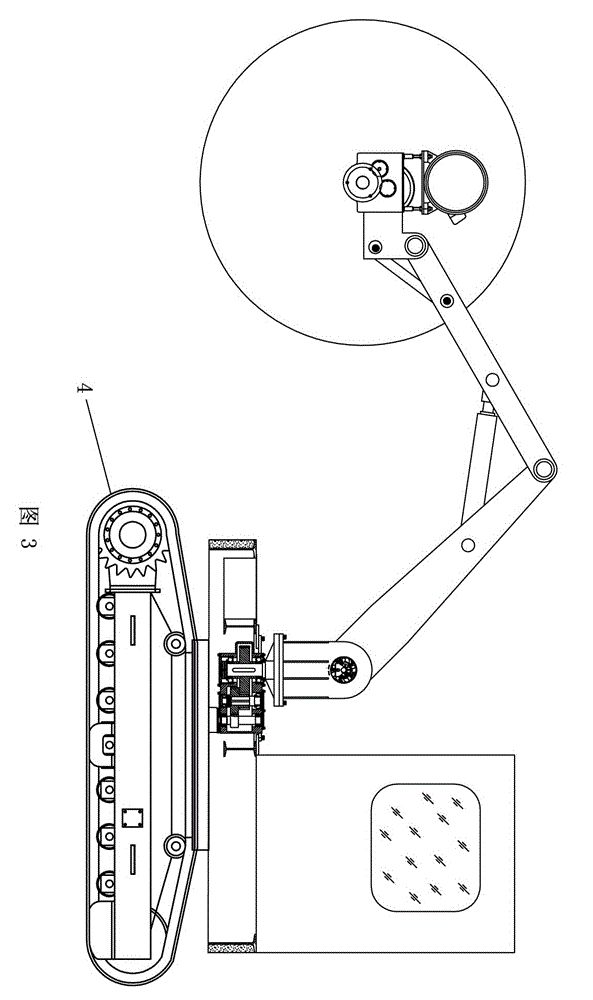

[0033] Refer to attached image 3 . The embodiment of this embodiment is basically the same as that of the first embodiment, the difference is that: the running mechanism 4 is a crawler belt, and the walking mode of the crawler belt is the prior art, and its running principle will not be described in detail here.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com