Hub oil storage system

An oil storage system and wheel hub technology, applied in the field of oil storage system, can solve the problems of poor fluidity of grease, waste of grease use, and large amount of oil storage, and achieve the effects of reducing frictional resistance, reducing pollution and slowing down wear

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0018] The present invention will be further described below through specific embodiments and in conjunction with the accompanying drawings.

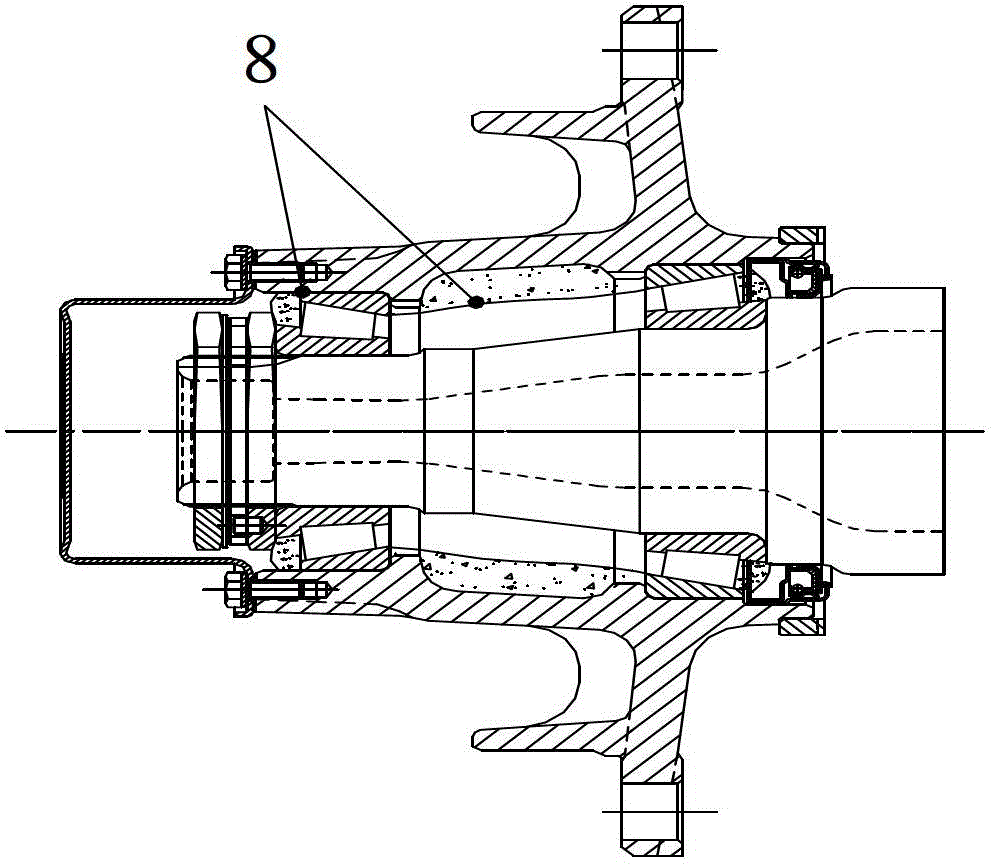

[0019] Such as figure 1 As shown, on the existing trailer axle, most of the lubricating grease 8 used for the lubrication of the inner and outer bearings of the axle is stored in the hub cavity between the hub and the axle head. Even when the axle rotates at a high speed, the grease in the hub cavity cannot enter the bearing. Internal lubrication.

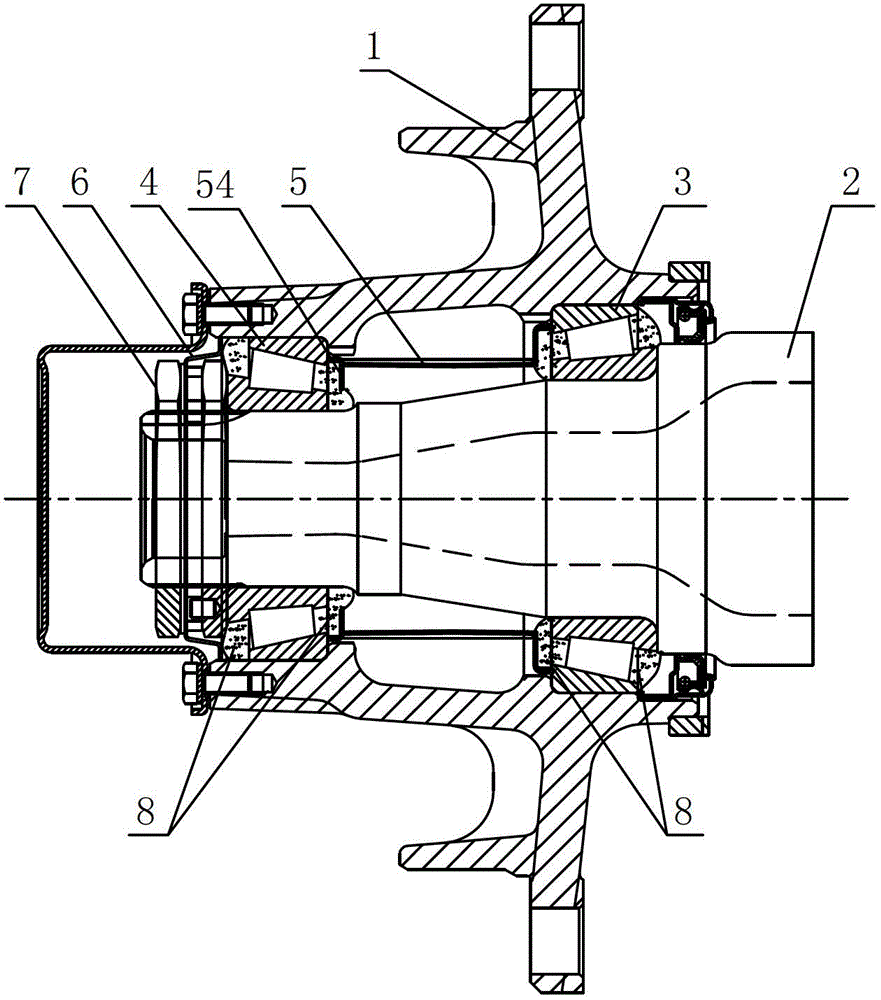

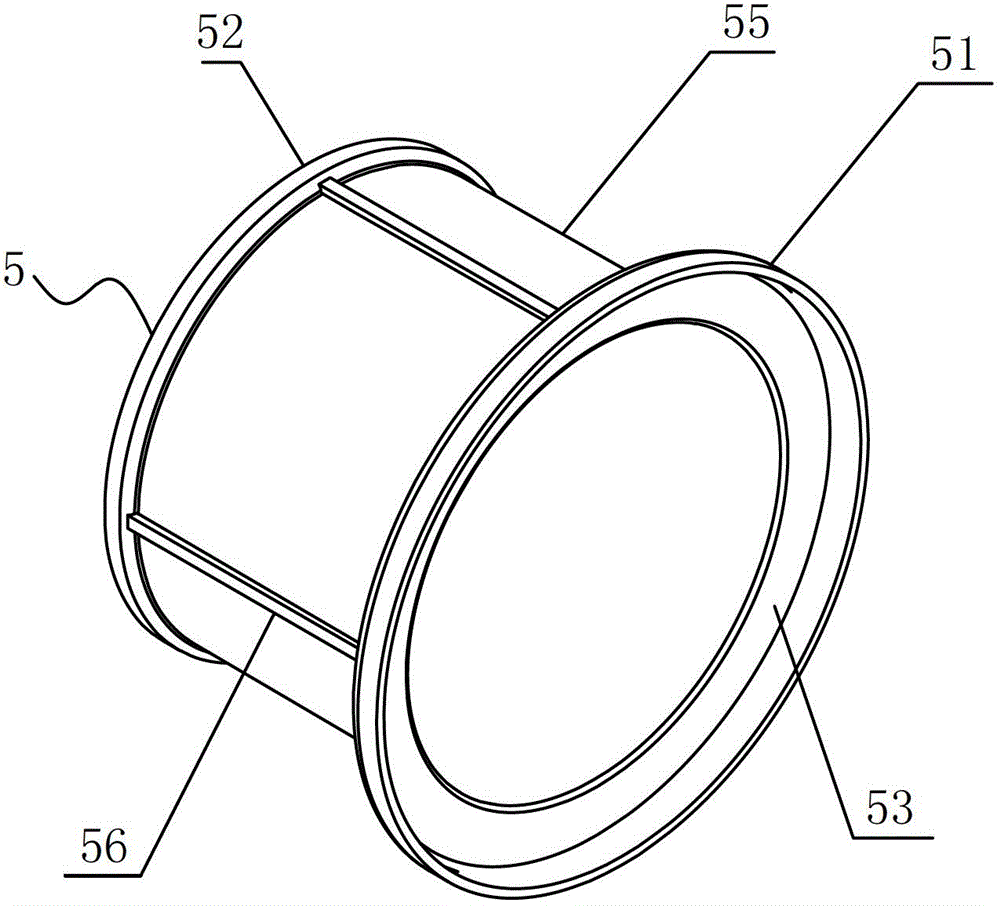

[0020] Such as figure 2 , 3 , 4, the present invention discloses a wheel hub oil storage system. The trailer axle is a follower axle, which bears the weight of the vehicle and the cargo load, and is used to support the rotation of the tire. It mainly includes the axle body, wheel hub 1, brake drum, brake shoe assembly, and camshaft assembly. The axle body is divided into shaft The tube and the shaft head 2 at both ends are two parts. The hub 1 and the brake drum assembly are assembled o...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com