Nozzle with Y-shaped air tap

A gas nozzle and nozzle technology, applied in filament/thread forming, textile and papermaking, fiber processing, etc., can solve problems such as poor flame resistance, anti-fouling, anti-pilling, etc., and achieve excellent performance and simple structure. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

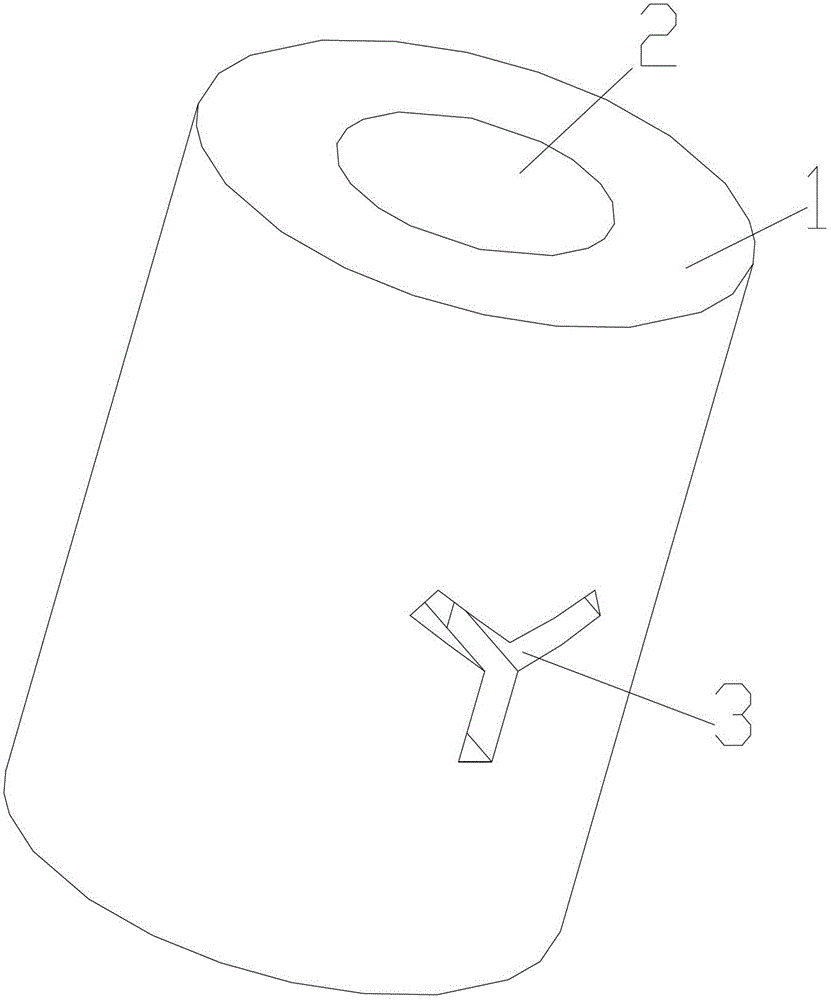

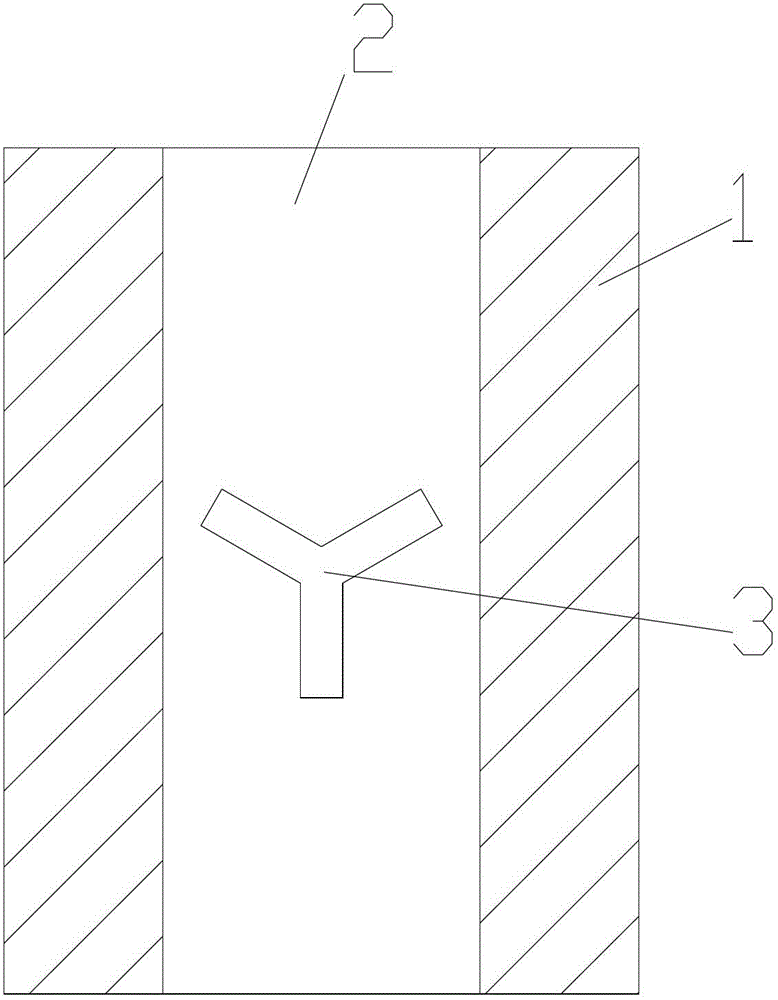

[0011] as attached figure 1 , 2 The nozzle with Y-shaped air nozzle shown in the present invention includes a housing 1; the housing 1 is provided with a guide wire groove 2; the housing 1 is provided with a Y-shaped air nozzle 3; The outlet of the Y-shaped air nozzle 3 faces the guide wire groove 2.

[0012] In the nozzle with a Y-shaped air nozzle according to the present invention, the Y-shaped air nozzle can blow air through the wire guide groove, so that particles are formed on the surface of the wire; the moisture absorption, dyeing, antistatic, The performances of flame resistance, anti-fouling and anti-pilling are excellent; the structure of the invention is simple and practical.

[0013] The above-mentioned embodiments are only to illustrate the technical conception and characteristics of the present invention. Substantial equivalent changes or modifications shall fall within the protection scope of the present invention.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com