Wireless video patrol inspection device of belt conveyor

A belt conveyor and wireless video technology, applied in transportation and packaging, underground transportation, television, etc., can solve the problems of coal mine safety production economic loss, cable failure, and staff safety, so as to improve transportation production efficiency and avoid personal injury Casualty accidents and the effect of ensuring safe production

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0021] Below in conjunction with accompanying drawing and specific embodiment the present invention is described in further detail:

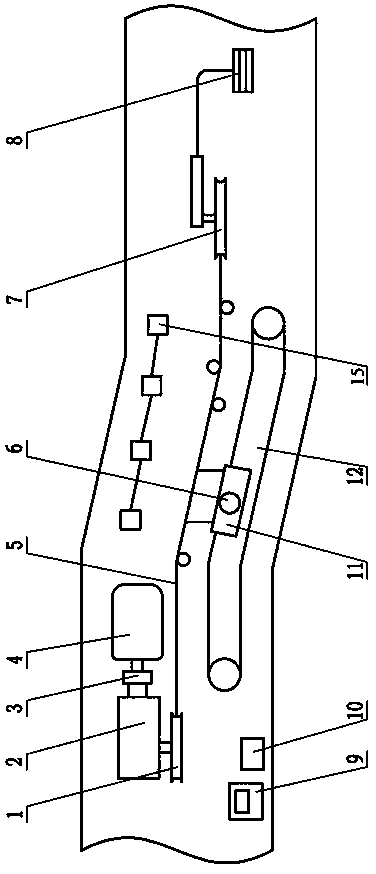

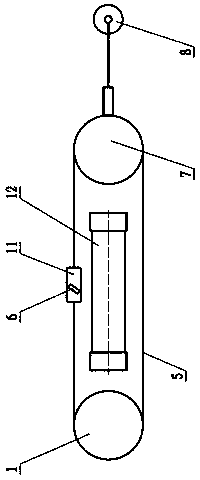

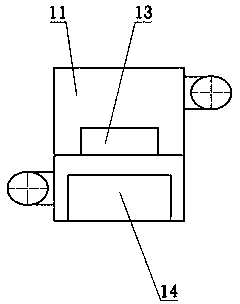

[0022] A wireless video inspection device for belt conveyors, which is used in the field of coal mines as an automatic inspection of transportation equipment. Its structure diagram is as follows figure 1 shown. It includes a monitor and a frequency conversion controller arranged in the control room; and a camera, a wireless video transmission module, a power supply module, a fixing mechanism, an operating mechanism and a driving mechanism arranged on one side of the belt conveyor.

[0023] Among them: the camera is used to collect the working status of the underground belt conveyor in real time, and transmit it to the display through the switchboard through the wireless communication network. The wireless video transmission module is used to convert the information collected by the camera into a wireless signal and transmit it wirelessly. The...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com