Steam turbine rotor

A steam turbine rotor and impeller technology, applied in mechanical equipment, engine components, machines/engines, etc., can solve the problems of reducing the strength of the main shaft and impeller, difficult assembly, low assembly efficiency, etc., to prevent loosening and sliding, low production cost, The effect of high production efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

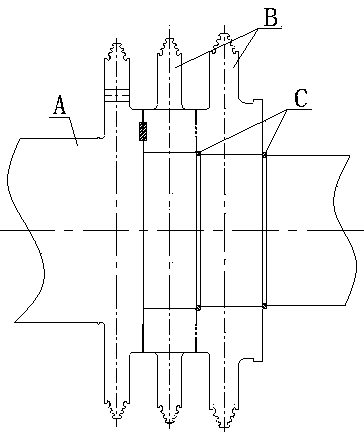

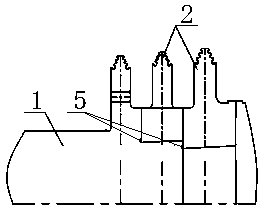

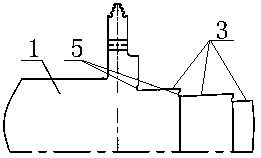

[0018] see figure 2 , image 3 and Figure 4 : The present invention comprises a main shaft 1 and impellers 2 of various levels, and the main shaft 1 and impellers 2 of various levels are set structures. Among them, the outer surface of the main shaft 1 is processed with the outer assembly surface 3 for assembling the impellers 2 of each level. The outer assembly surfaces 3 of each level have tapers respectively. The taper of the outer assembly surfaces 3 of each level is 1:60 respectively. The root of the surface 3 is provided with a concave chamfered stress groove 5, and the outer surface of the main shaft 1 is stepped. The impellers 2 of each stage have ring-shaped internal assembly surfaces 4 respectively, and the internal assembly surfaces 4 also have tapers. After being heated, the first-stage impeller 2 is assembled on the corresponding outer assembly surface 3 of the main shaft 1 through its own inner assembly surface 4, and the cooled impellers 2 of each stage and...

Embodiment 2

[0020] The other structures of this embodiment are the same as those of Embodiment 1, except that the taper of the outer assembly surface on the main shaft is 1:85 respectively.

Embodiment 3

[0022] The other structures of this embodiment are the same as those of Embodiment 1, except that the taper of the outer assembly surface on the main shaft is 1:66 respectively.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com