Novel mechanical sealing structure for water seal on bottom of boiler

A mechanical seal and boiler technology, applied in combustion methods, lighting and heating equipment, removal of solid residues, etc., can solve the problems of extrusion deformation and tilt of baffles, affecting the longitudinal expansion of the water wall of the boiler body, etc., to improve efficiency and ensure Safe operation, the effect of eliminating pollution equipment

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

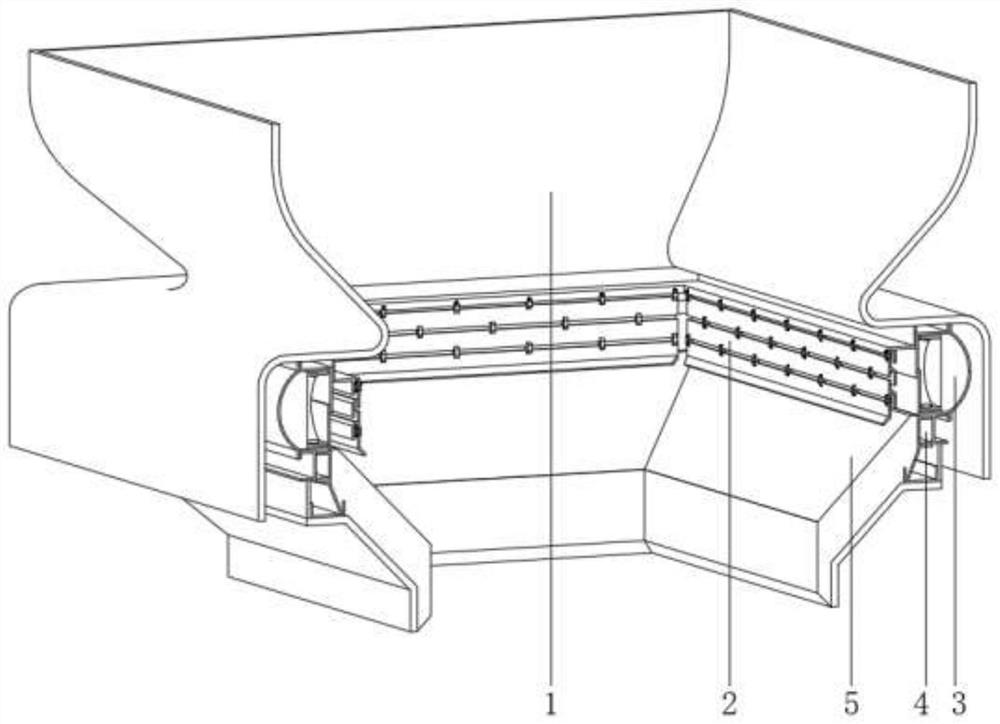

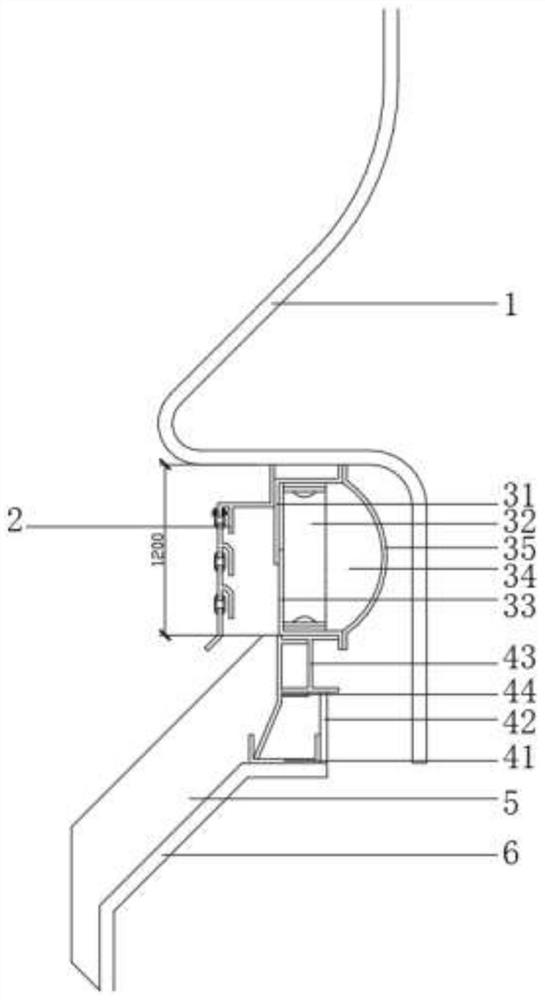

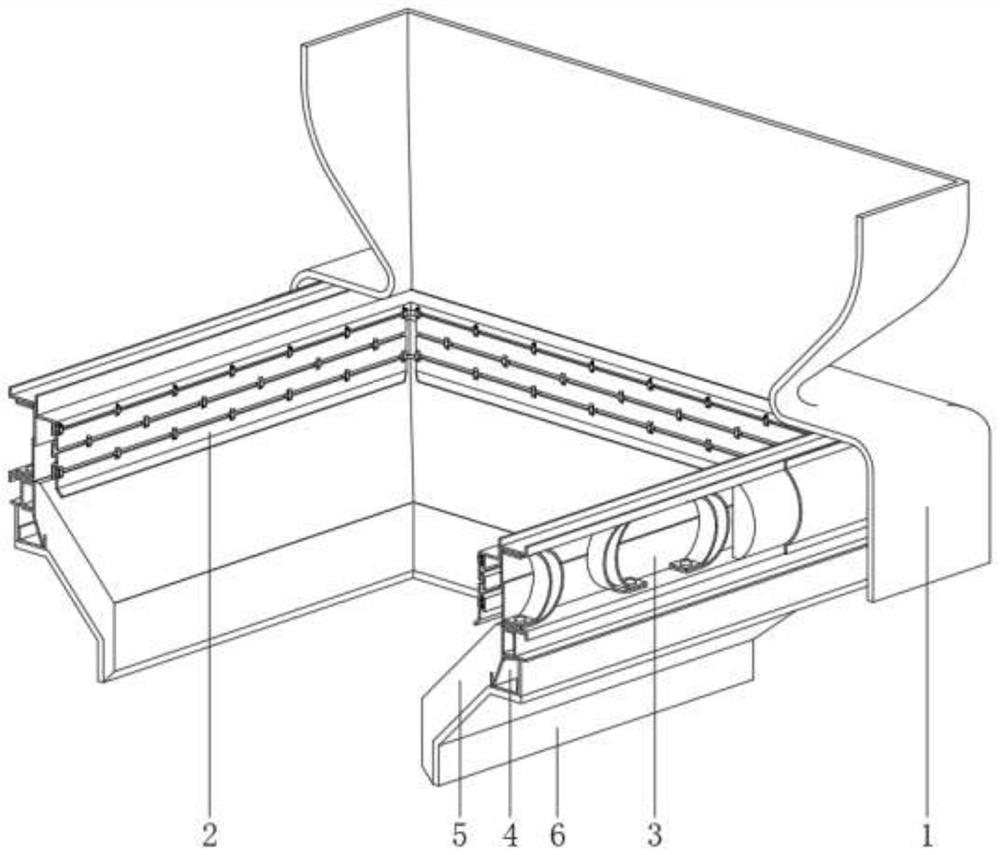

[0022] For the embodiment, please refer to Figure 1-4, a new type of water seal mechanical seal on the bottom of the boiler

[0023] structure, including a water-cooled wall 1, the lower part of the water-cooled wall 1 is provided with a slag curtain 2, one side of the slag curtain 2 is provided with a mechanical seal mechanism 3, and the bottom surface of the mechanical seal mechanism 3 is provided with a water seal groove The modified base 4 is provided with a buffer layer 5 on one side of the modified base 4 of the water seal tank.

[0024] Embodiment, please refer to Fig. 2 emphatically, the distance between the top surface of the modified base 4 of the water seal tank and the bottom surface of the water wall 1 is not less than 1200mm. The design elevation may have a certain amount of sinking. This guarantees an installation space of 1200 mm for the mechanical seal.

[0025] Embodiment, please refer to Figures 5-6, the slag curtain 2 includes a curtain fixing plate 21, t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com