Automated mechanical transmission

A kind of automatic transmission, mechanical technology, applied in the direction of automatic clutch, mechanical equipment, transmission box, etc., can solve the problems of short service life, poor sensitivity, adverse effects of fuel consumption, etc., and achieve the effect of avoiding complex structure and good fuel saving effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

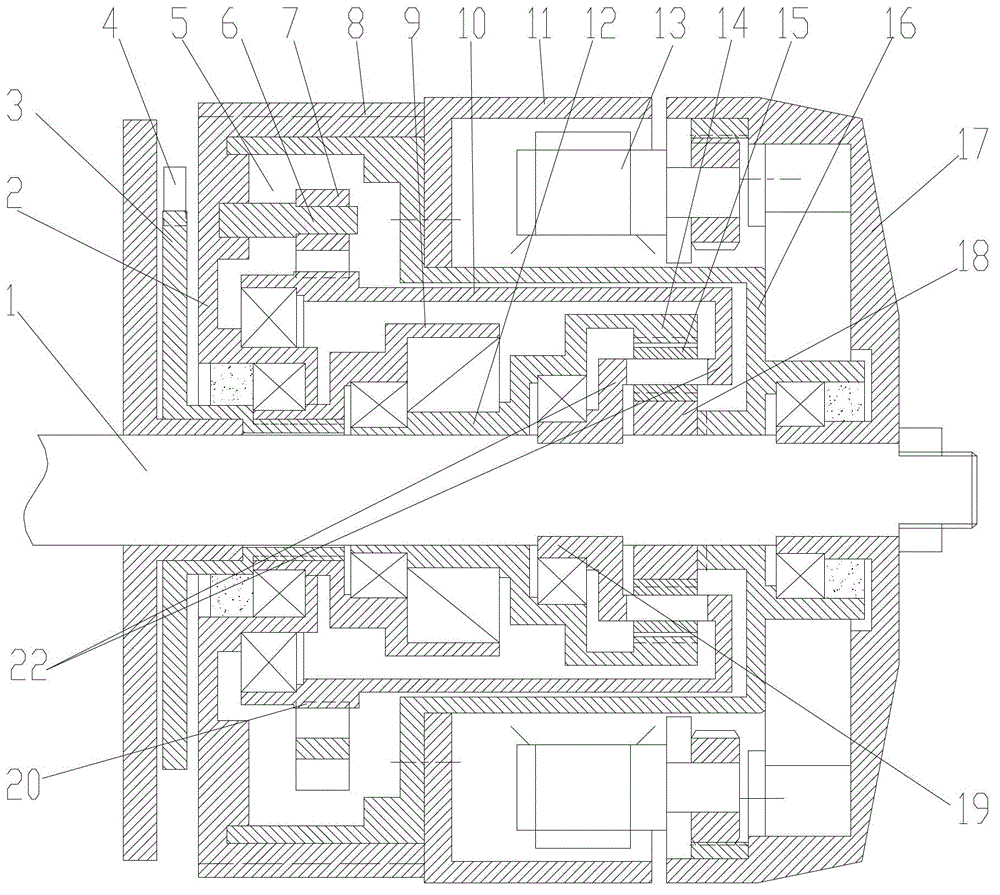

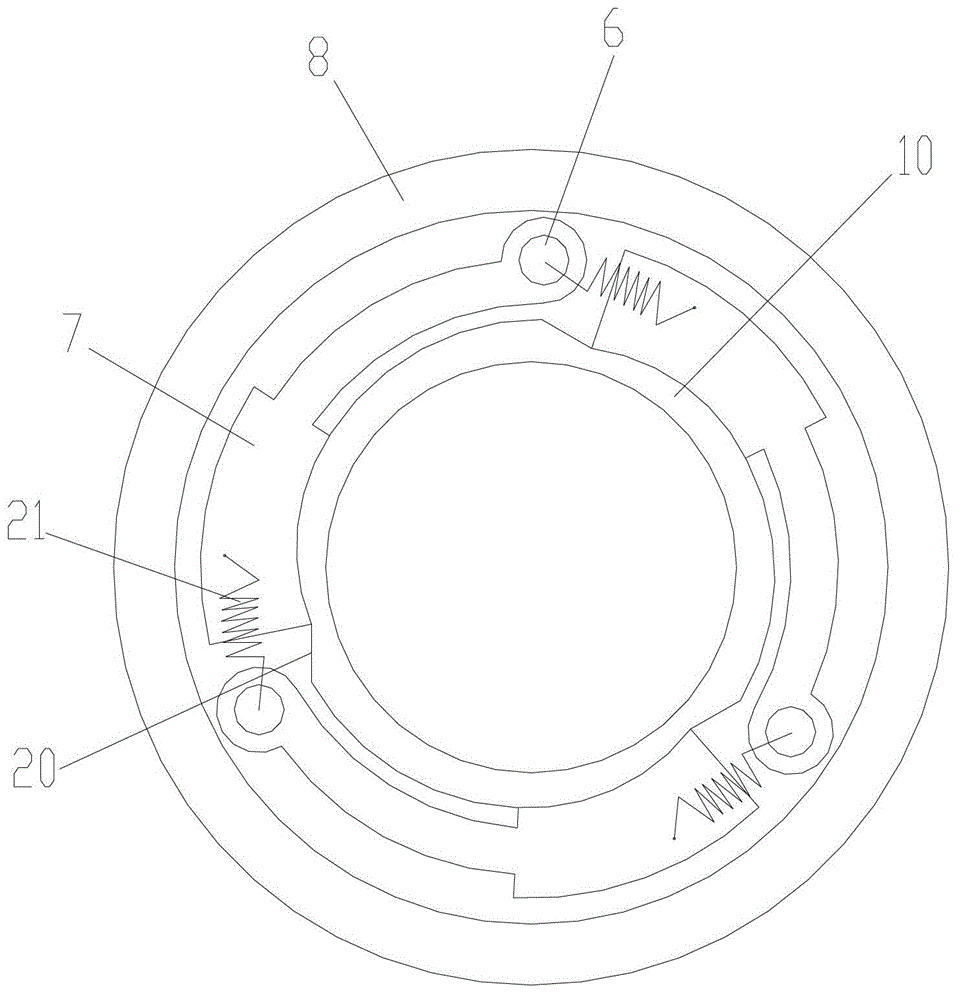

[0015] figure 1 It is a structural schematic diagram of the present invention, figure 2 It is a structural schematic diagram of the torque clutch of the present invention, as shown in the figure: the mechanical automatic transmission of this embodiment includes a power input member 8, a slow gear transmission assembly, a centrifugal clutch 13 and a power output member 1, and the power input member 8 passes through The centrifugal clutch 13 transmits power to the power output member 1, and the centrifugal clutch 13 is used for clutching and disconnecting between the power input member 8 and the power output member 1 when the rotational speed of the power output member 1 is lower than or reaches a set value. Open or engage to transmit fast gear power, forming the first fast gear transmission route; the power input member 8 also transmits the slow gear power to the power output member 1 through the slow gear transmission assembly in a manner that can be overtaken by the fast gea...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com