Crossing protector for submarine pipeline

A technology for protection devices and submarine pipelines, applied in pipeline protection, pipeline laying and maintenance, pipeline damage/wear prevention, etc., can solve problems such as high construction cost, heavy construction workload, pipeline leakage, etc., to reduce workload and construction cost effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

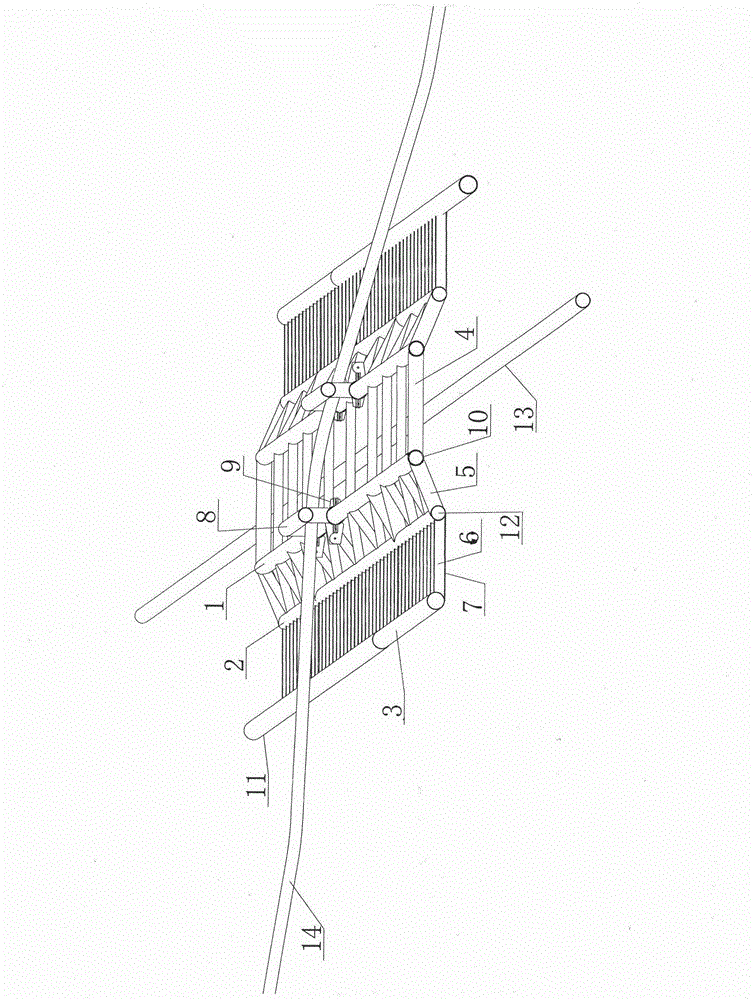

[0011] like figure 1 As shown, the present invention is a left-right symmetrical structure. Two top round pipes 1 are located directly above the original pipeline 13, and their outer sides are wrapped with a layer of rubber pad 10. The distance between the two top round pipes 1 is preferably 2m, supported by the top 4 are connected, and the top support 4 is a round tube member; the two bottom inner round tubes 2 are located obliquely below the two top round tubes 1, respectively, and are connected by a slope support 5. The slope gradient is preferably 20°-30°, and the slope support 5 is a round pipe member; the contact area between the outer bottom round pipe 3 and the newly laid pipeline 14 is wrapped with a layer of rubber pad 11; 6 is an I-beam, and an anti-settling plate 7 is arranged at the bottom thereof. The width of the anti-settling plate 7 is determined by calculation to meet the anti-sinking requirements, and at the same time ensure that the newly laid pipeline 14 n...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com