Outer water-cooling and inner thermal-insulating high-pressure and high-temperature expansion joint

A high-pressure, high-temperature, expansion joint technology, which is applied in the field of expansion joints for high-temperature aerodynamic pipelines, can solve the problems that the expansion joint cannot meet the design conditions and the design temperature is high, and achieve no abnormal deformation compensation action, improved bearing capacity, and safe and reliable structure Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0023] The present invention will be further described below in conjunction with accompanying drawing:

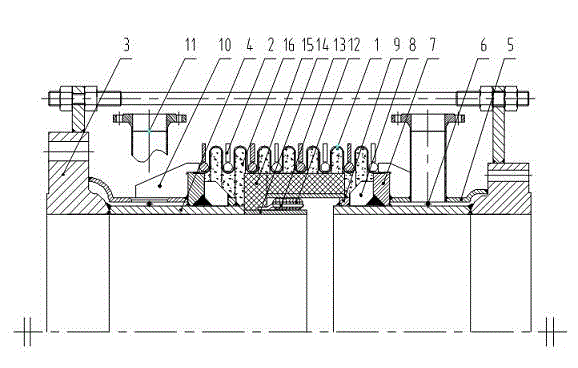

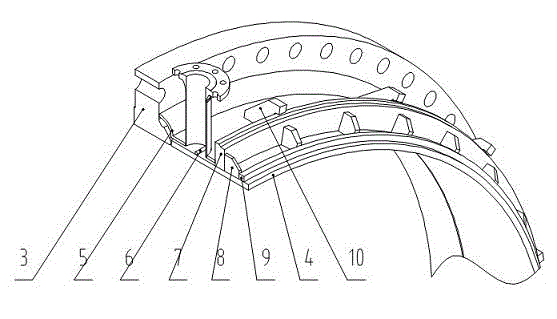

[0024] Such as figure 1 , 2 As shown, the present invention includes a bellows 1, and the two ends of the bellows 1 are respectively connected with two pressure-bearing ring plates 7. The two pressure bearing ring plates 7 are installed on the outer sidewalls of the two connecting pipes 4 respectively, and the outer ends of the two connecting pipes 4 are connected with the respective corresponding flanges 3 . Between the pressure-bearing ring plate 7 and the flange 3, there is a water jacket 5 on the outside of the connecting pipe 4, and the water inlet and outlet 11 are arranged on both sides of the water jacket 5, and the high-speed circulating water is used to cool the part to prevent it. Deformation failure under high temperature and pressure. The welding end of the water jacket 5 and the flange 3 adopts an arc-shaped design, which ensures the amount of water filling...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com