Rubber rod with charging port rubber plug

A technology of rubber plugs and rubber rods, which is applied to the components of lighting devices, lighting devices, lighting and heating equipment, etc., can solve problems such as difficult assembly, failure to charge, and troubles for customers, and achieve difficult assembly, reliable use, and assembly convenient effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

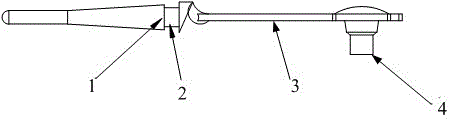

[0012] see figure 1 , a rubber rod with a charging port rubber plug, the charging port rubber plug 4 can cover the electrical charging port, the charging port rubber plug 4 is arranged at one end of the rubber rod, and the other end of the rubber rod is provided with a hand-drawn assembly end structure 1, Hand-drawn assembly end structure 1 can be inserted into the electrical appliance assembly port and fixed on the electrical appliance, wherein the assembly end structure is provided with a handle structure, the assembly end structure is connected or integrated with the handle structure through the connecting arm 3, the handle structure The diameter is smaller than the diameter of the electrical assembly port.

[0013] In this embodiment, the structure of the assembly end is provided with an anti-retraction groove 2, and the diameter of the anti-retraction groove 2 is not larger than the diameter of the assembly port of the electrical appliance. Due to the good stretching el...

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap