Measurement apparatus of metal band steel ring for continuously variable transmission

A technology of continuously variable transmission and measuring devices, applied in measuring devices, instruments, etc., can solve problems such as precision measurement of metal closed-loop circumference, achieve the effect of rapid grouping and perfect quality management system

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

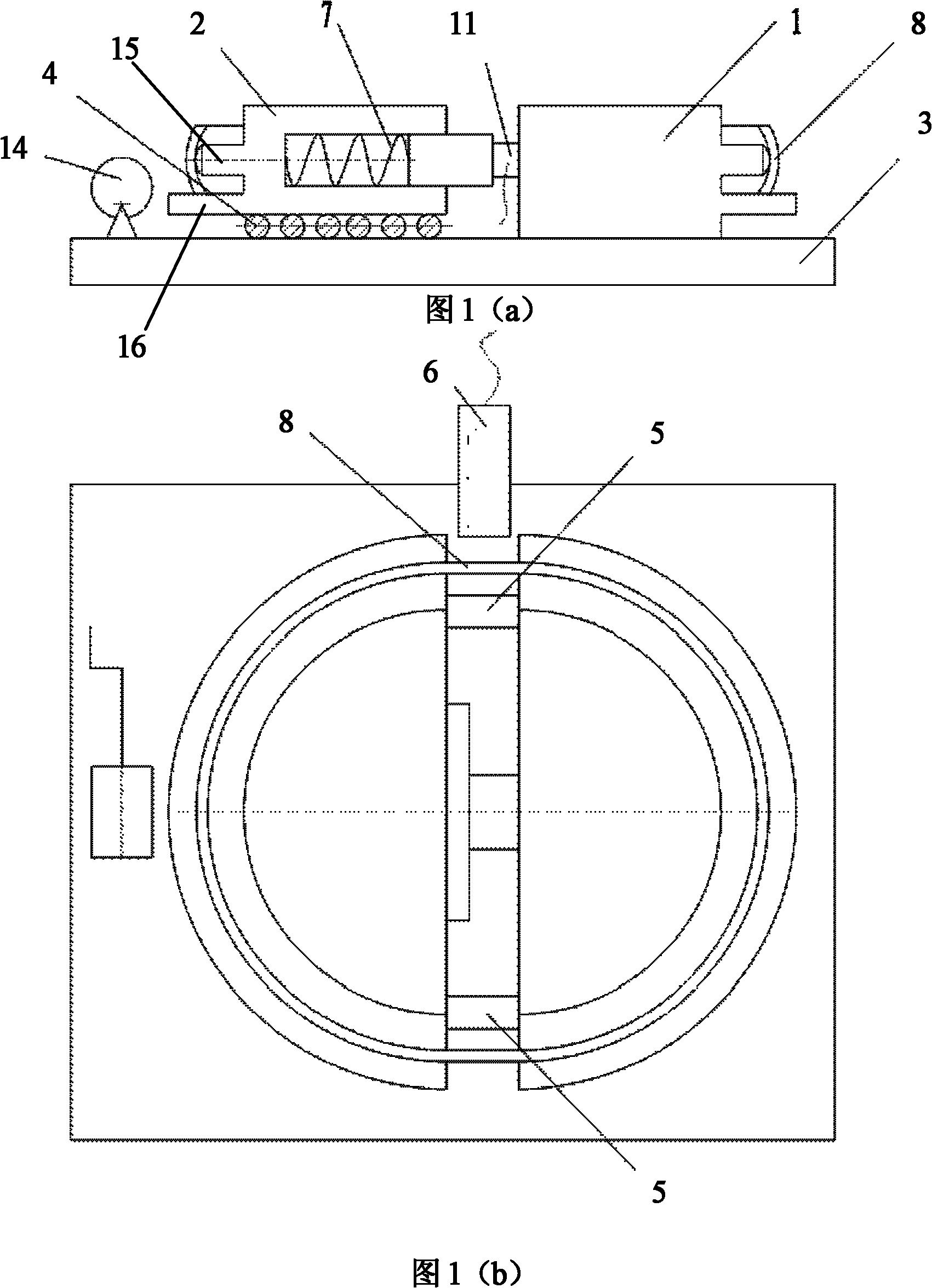

[0027] As shown in Figure 1, the measuring device for the inner circumference of the metal strip steel ring for the continuously variable transmission of the present invention mainly includes: fixing the mounting plate 1 of the test piece, moving the mounting plate 2 of the test piece, a base 3, a linear bearing or a linear guide rail 4. Pressure sensor 5, coding or code reader 6, spring 7, steel ring 8, displacement sensor 11, eccentric wheel 14, etc. The specific structure is as follows:

[0028] As shown in Figure 1, the fixed DUT mounting plate 1 is fixed on the base 3, the moving DUT mounting plate 2 is installed on the base 3 through the linear bearing (or linear guide rail) 4, and the fixed DUT is mounted on the base 3. A spring 7 is installed in the middle of the disk 1 and the moving DUT mounting disk 2, a displacement sensor 11, a pressure sensor 5, and a displacement sensor for measuring the mutual position and tension between the fixed DUT mounting disk 1 and the m...

Embodiment 2

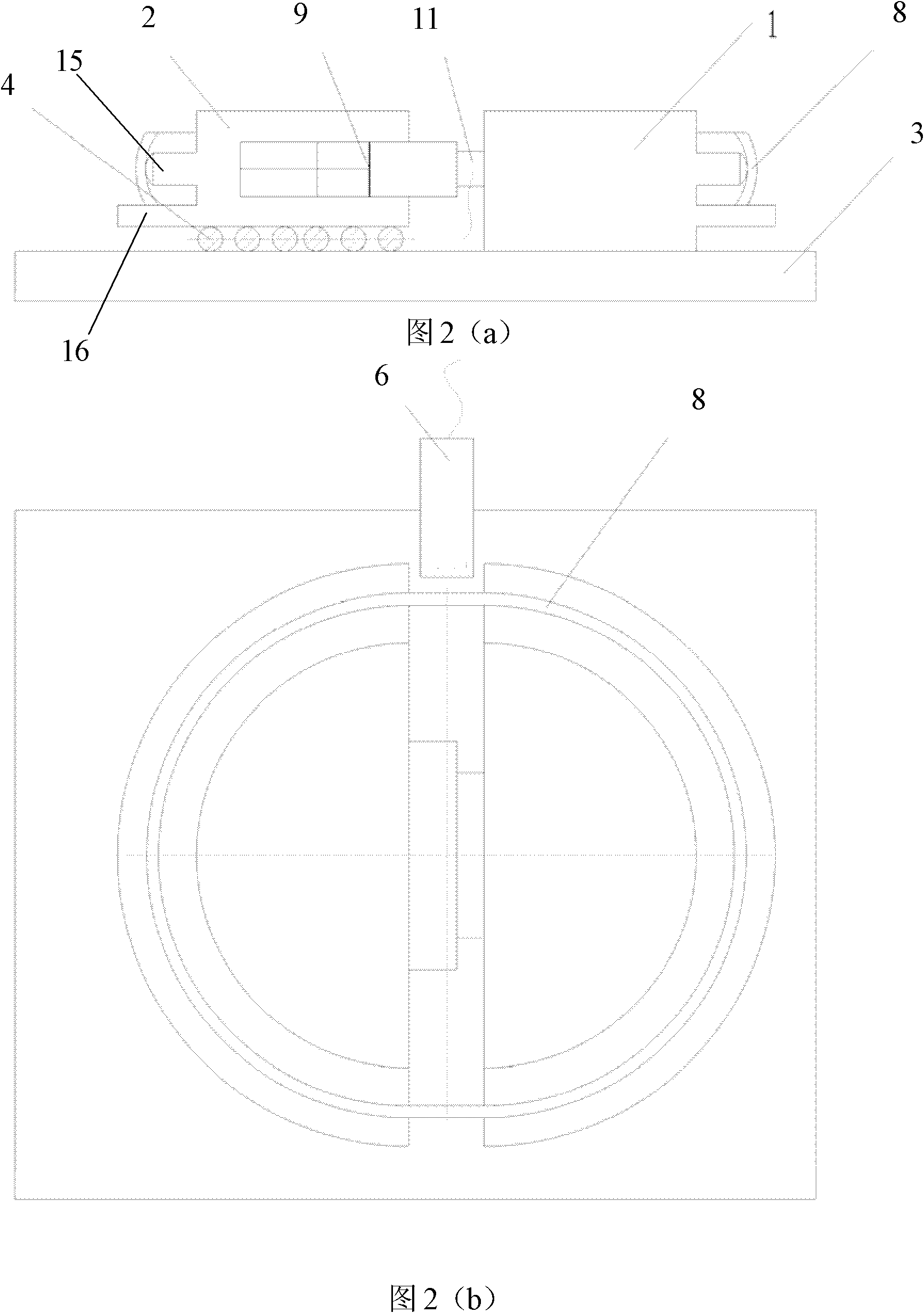

[0033] The difference from Embodiment 1 is that the measuring device for the metal strip and steel ring of the continuously variable transmission of the present invention mainly includes: fixing the mounting plate 1 of the test piece, moving the mounting plate 2 of the test piece, a base 3, a linear bearing or a linear guide rail 4. Code printing or code reader 6, steel ring 8, pneumatic or hydraulic piston 9, displacement sensor 11, etc. The specific structure is as follows:

[0034] As shown in Figure 2, the fixed DUT mounting plate 1 is fixed on the base 3, the moving DUT mounting plate 2 is installed on the base 3 through the linear bearing (or linear guide rail) 4, and the fixed DUT is mounted on the base 3. A pneumatic or hydraulic piston 9 is installed between the disk 1 and the moving DUT mounting disk 2, and a displacement sensor 11 for measuring the mutual position between the fixed DUT mounting disk 1 and the moving DUT mounting disk 2, and the displacement sensor 1...

Embodiment 3

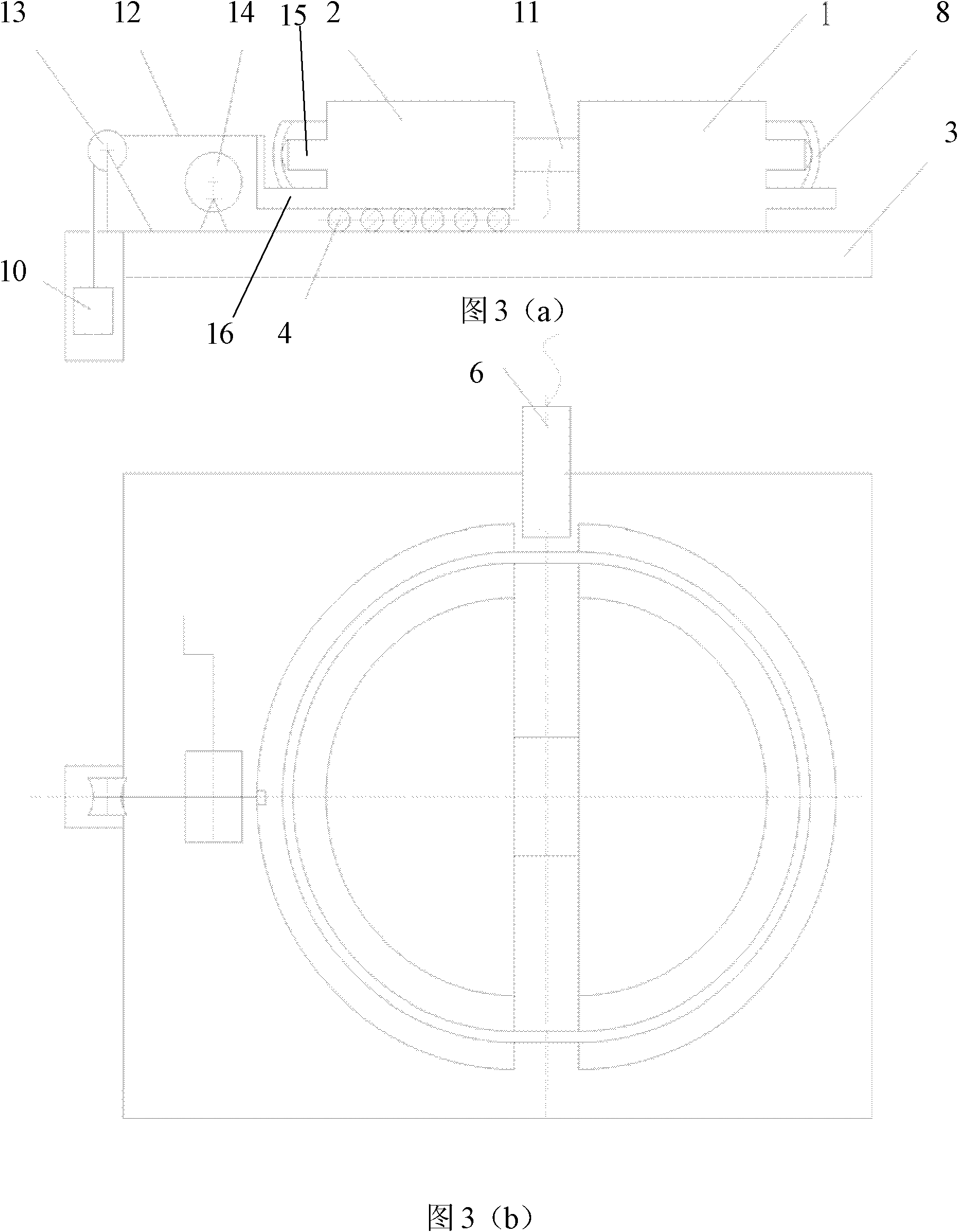

[0037] The difference from Embodiments 1 and 2 is that the measuring device for the metal strip and steel ring of the continuously variable transmission of the present invention mainly includes: fixing the mounting plate 1 of the test piece, moving the mounting plate 2 of the test piece, a base 3, a linear bearing or Linear guide rail 4, coding or code reader 6, steel ring 8, weight 10, displacement sensor 11, flexible element 12, pulley 13, eccentric wheel 14, etc. The specific structure is as follows:

[0038]As shown in Figure 3, the fixed DUT mounting plate 1 is fixed on the base 2, the moving DUT mounting plate 2 is installed on the base 3 through the linear bearing (or linear guide rail) 4, and the fixed DUT is installed Displacement sensors 11 for measuring mutual positions between the fixed DUT installation disk 1 and the mobile DUT installation disk 2 are installed between the disk 1 and the moving DUT installation disk 2, and the weight 10 is connected to the On the...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com