Illuminating device and imaging method for online detection

A technology of detected and fixed devices, which is applied in the direction of measuring devices, optical devices, and optical testing of flaws/defects, etc., can solve the problems of complicated detection mechanism, restricted detection speed, and reduced system reliability, so as to improve system reliability , Mechanism complexity reduction, effect of reducing complexity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

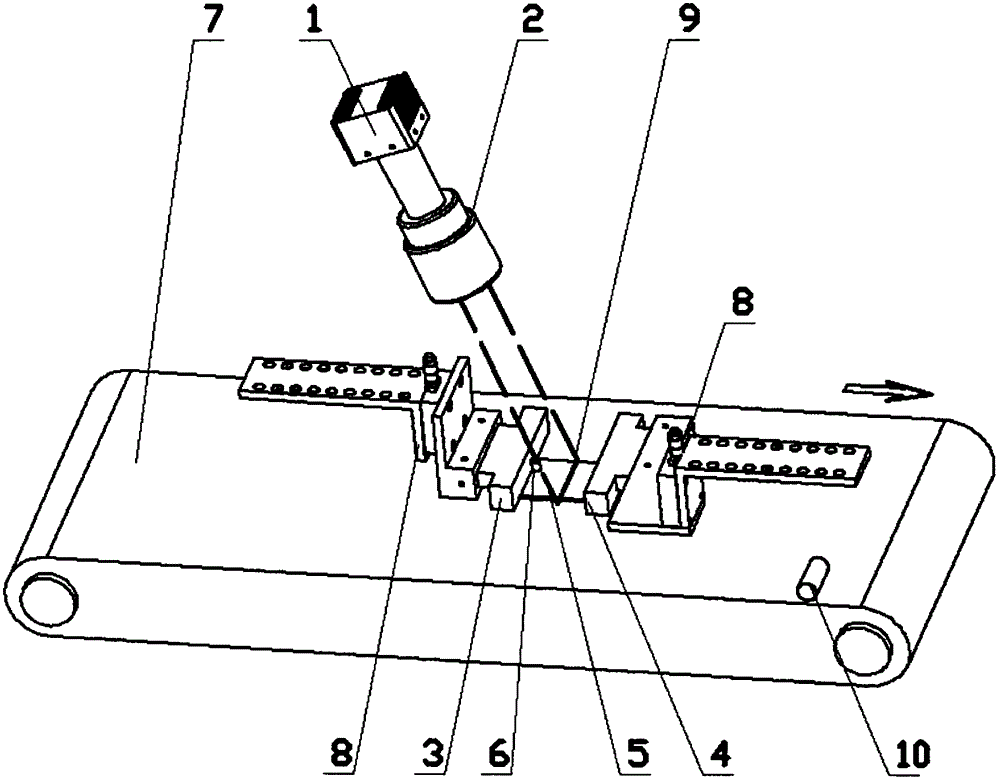

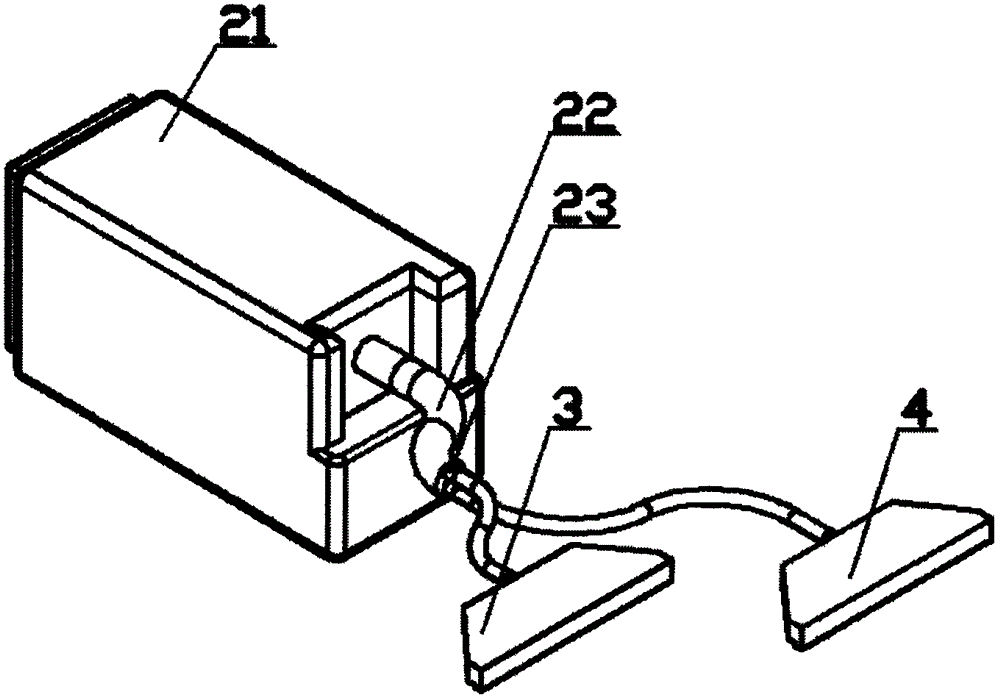

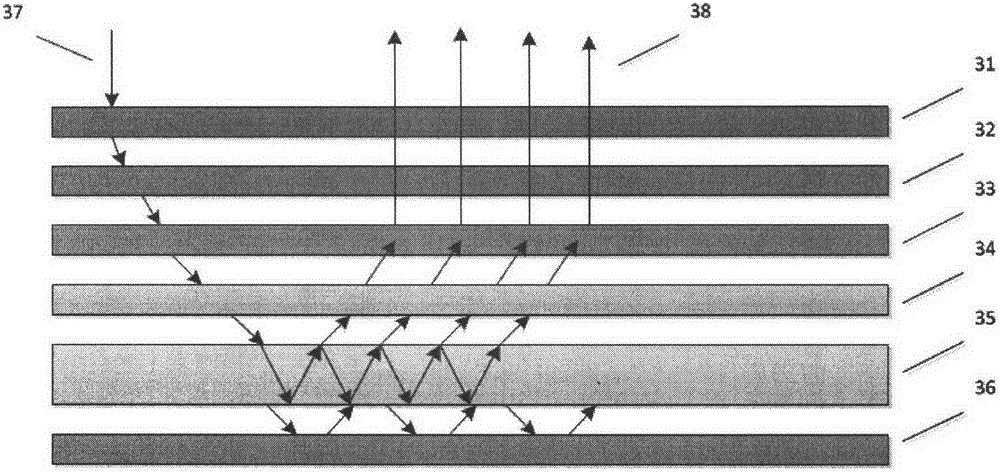

[0032] An embodiment of the present invention provides an online detection lighting device, which is composed of a front strip light source group 3 , a rear strip light source group 4 , a light source fixing device 8 , a lens 2 , a camera 1 and a photosensitive sensor 6 . The camera 1 is connected to the rear end of the lens 2 and is fixed above the conveyor belt 7 together. Lens 2 adopts a large field of view industrial lens to meet the imaging requirements of a series of medium-sized workpieces. The front strip light source group 3 and the rear strip light source group 4 are located above the conveyor belt 7 and below the camera 1 and the lens 2 . The front bar-shaped light source group 3 is the front light source, which is located at the direction where the detected workpiece 5 enters the device.

[0033] The front bar-shaped light source group 3 and the rear bar-shaped light source group 4 are fixed by the light source fixing device 8, and the light source fixing device 8...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com