Acoustic emission detection device and method for detecting bottom of storage tank in confined space

An acoustic emission detection, confined space technology, applied in the direction of material analysis using acoustic emission technology, can solve the problems of complex tank chamber structure, complex drilling technology, limited space, etc., to ensure reliability and good economy , the effect of high safety

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

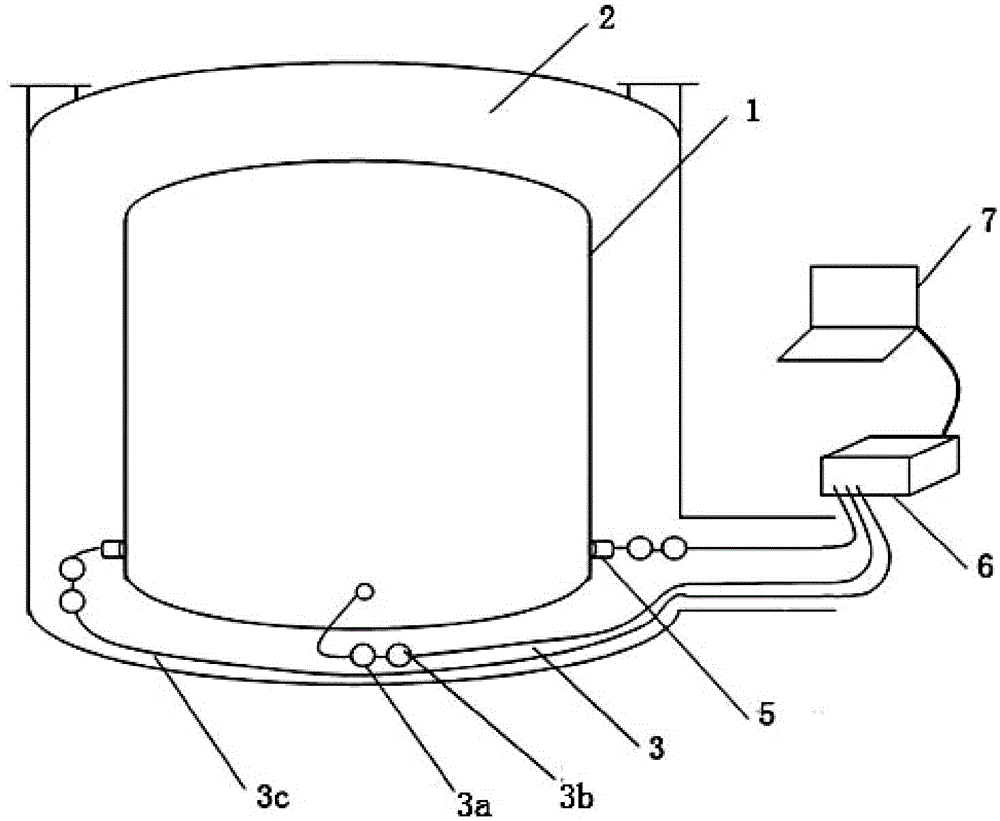

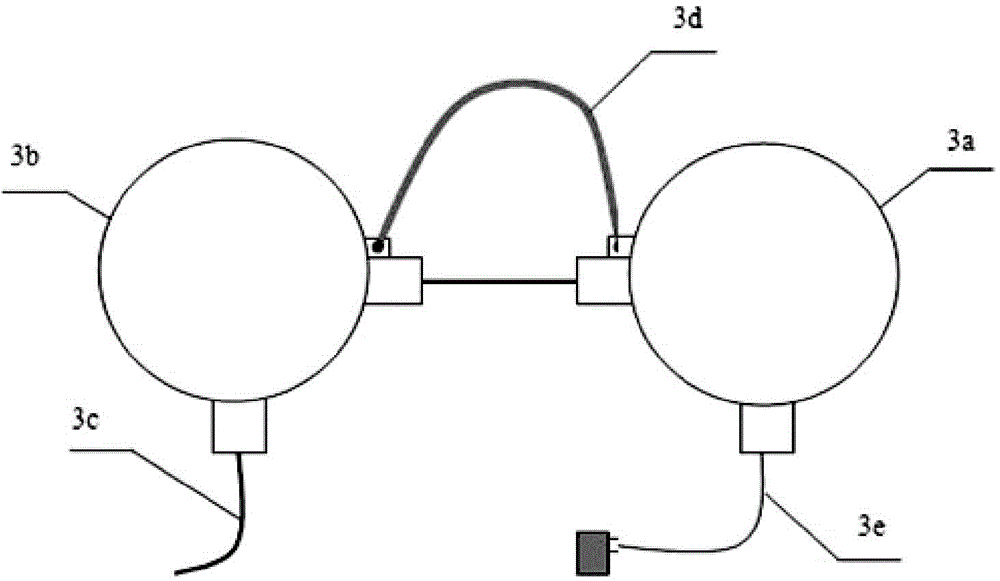

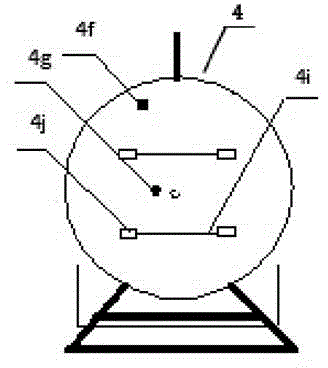

[0028] refer to Figure 1 to Figure 4 , the acoustic emission detection device at the bottom of the storage tank in the confined space of the present invention, from figure 1 It can be seen from the figure that the storage tank 1 is installed in the tank chamber 2, and the space left after the storage tank 1 is installed in the tank chamber is narrow. In the present invention, the acoustic emission detection device at the bottom of the storage tank includes: a plurality of emission sensors 5, an explosion-proof cable device 3, an acoustic emission host 6, a computer 7, and a lead core. Each part will be described in detail below:

[0029] A plurality of acoustic emission sensors 5 are evenly arranged on the same horizontal circumference of the storage tank wall 1, and each sensor is responsible for detecting an area on the storage tank, and these acoustic emission sensors convert mechanical vibrations of the storage tank into electrical signals; the acoustic emission The sens...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com