Tooling structure for presetting permeability quotient (PQ)-type magnetic cores

A magnetic core and preset technology, applied in the manufacture of inductors/transformers/magnets, electrical components, circuits, etc., can solve the problems of inability to precisely control the distance between tapes, high defect rate of magnetic cores, slow tapes, etc., to achieve simple structure, reduce The effect of defect rate and improving production efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0015] The specific embodiments of the present invention will be further described below in conjunction with the accompanying drawings.

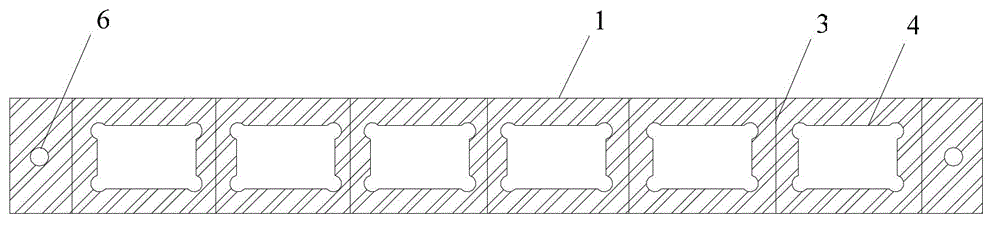

[0016] The present invention mainly includes upper plate 1 ( image 3 ) and lower plate 2 ( Figure 4 ) in two parts.

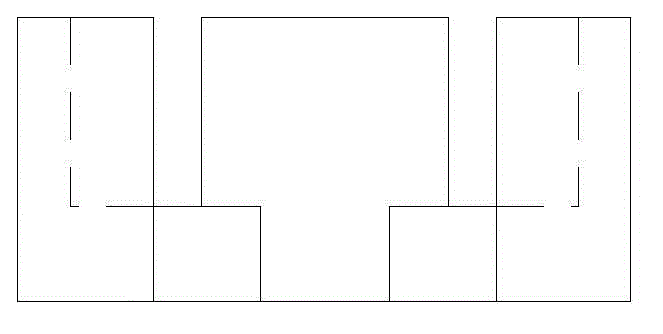

[0017] Such as image 3 As shown, the strip-shaped upper plate 1 is divided into a plurality of preset areas by the cutting tape positioning line 3 on its surface, and each preset area is provided with a preset hole 4 that runs through the upper plate 1, and the preset hole 4 It is used to place the PQ type magnetic core to be preset, and the depth of the preset hole 4 is equal to the height of the PQ type magnetic core to be preset.

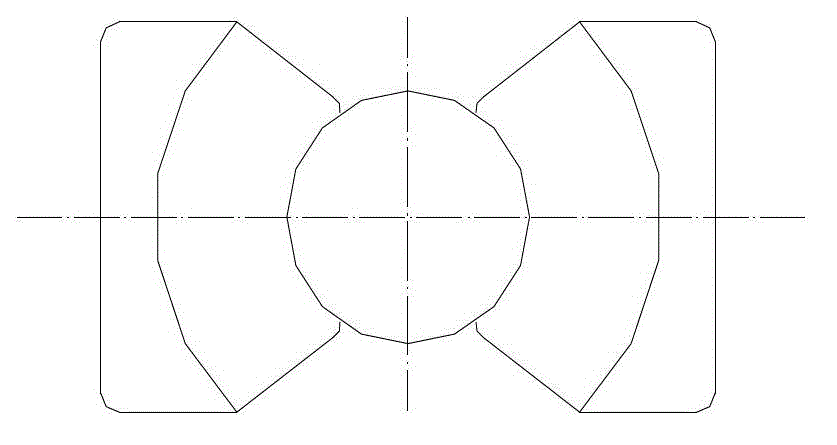

[0018] Such as Figure 4 As shown, the surface of the elongated lower plate 2 is provided with a plurality of bosses 5 corresponding to the positions of the preset holes 4 of the upper plate 1 . The size of the boss 5 is smaller than the size of the preset hole 4 .

[0019] Such as Fi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com