Movable contact spring of relay

A technology of moving reeds and relays, applied in the field of moving reeds, can solve the problems that the moving reeds cannot be easily separated and the contact resistance of the moving reeds is poor.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0014] The present invention will be further described below in conjunction with accompanying drawing.

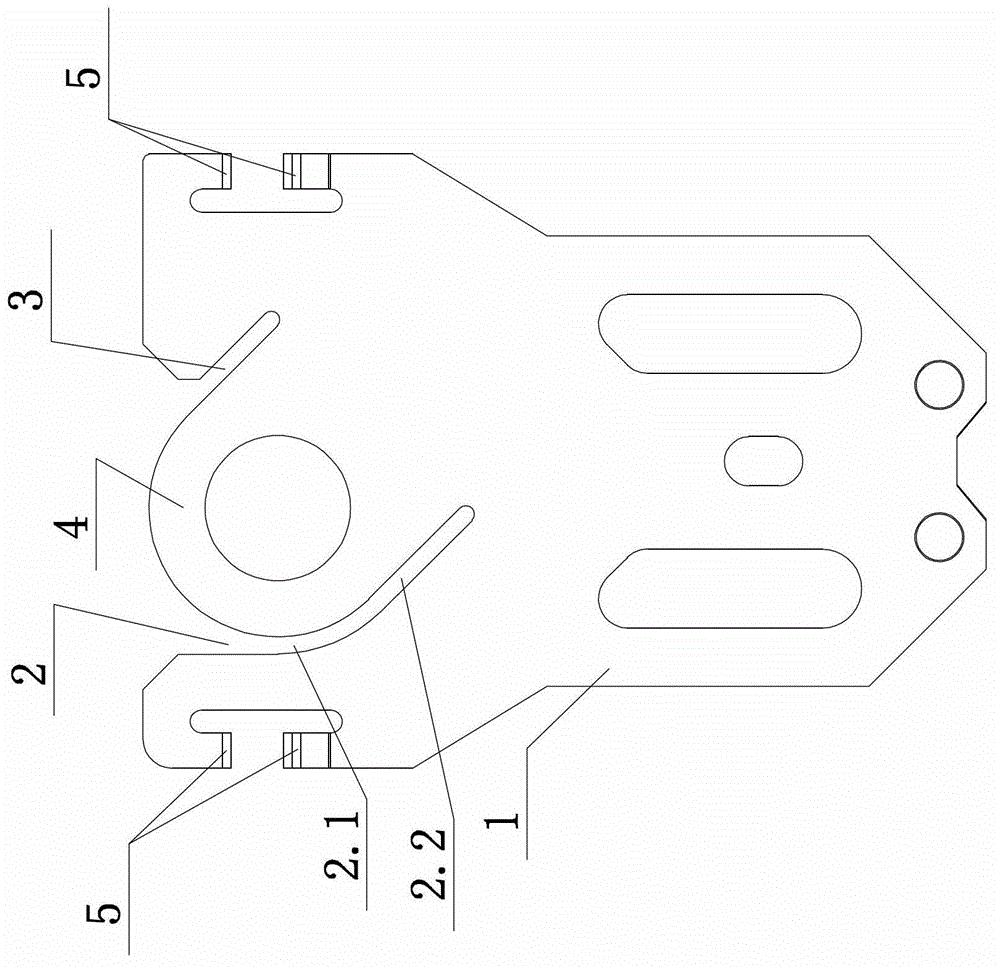

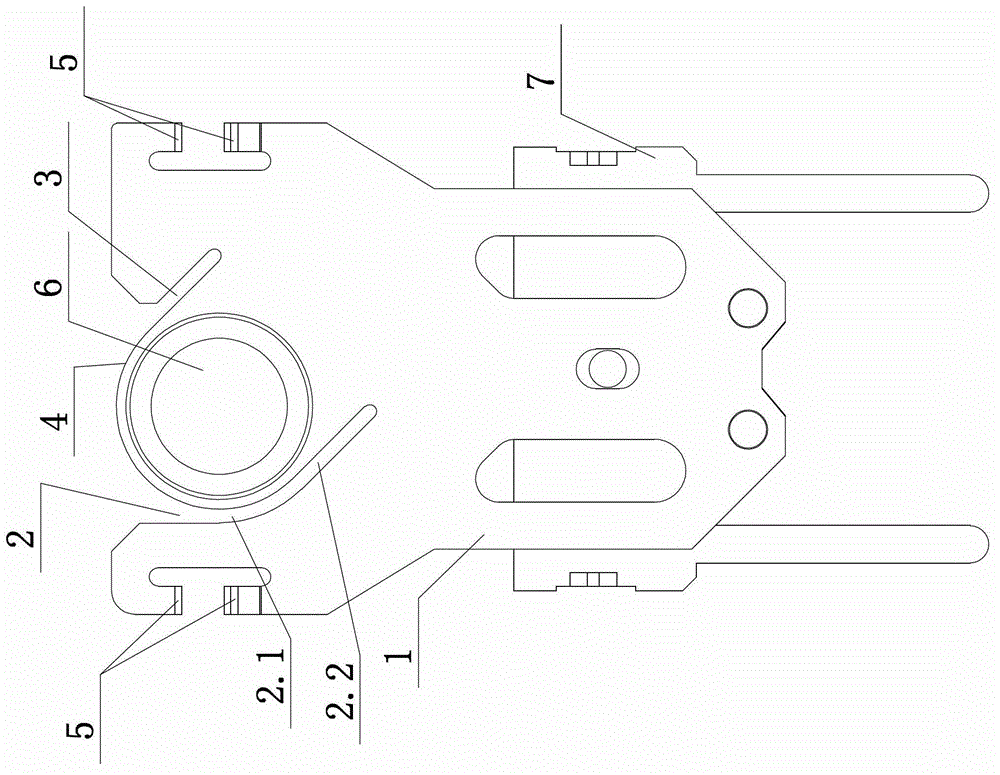

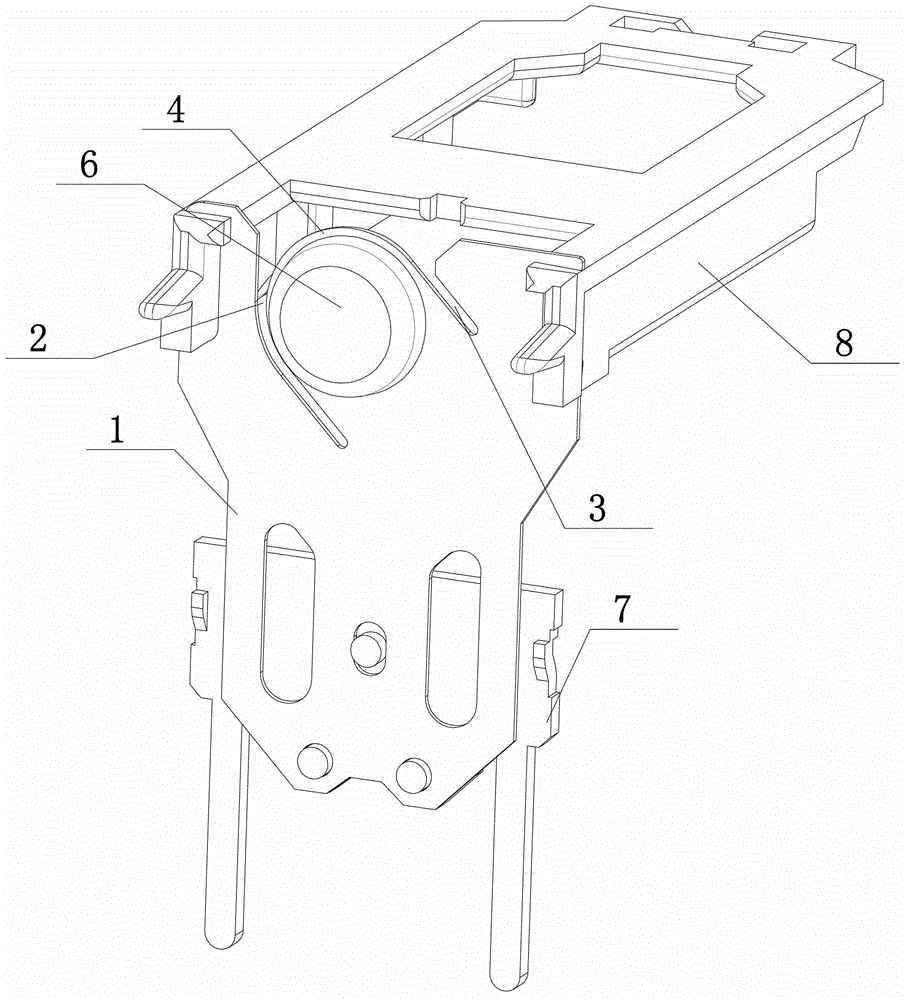

[0015] The moving reed of the relay of the present invention includes a body 1, the body 1 has a first cutout 2 and a second cutout 3, and the part of the body 1 between the first cutout 2 and the second cutout 3 is installed as a movable contact part 4.

[0016] The first incision 2 is formed by sequentially connecting the arc portion 2.1 and the straight portion 2.2; the second incision 3 is a straight incision.

[0017] The straight portion 2.2 of the first cutout 2 and the second cutout 3 are parallel to each other.

[0018] Both the straight line portion 2.2 and the second cutout 3 are oblique cutouts.

[0019] The inclination angle of the oblique cut is 45 degrees, and the inclination angle can also be 30 degrees, 40 degrees, 50 degrees, 55 degrees or the like.

[0020] In order to easily understand the moving reed of the relay of the present invention, figure 2 ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com