Needle handle sleeve for bone puncture needle

A bone-piercing needle and needle handle technology, applied in the field of medical and health equipment, can solve the problems of inconvenient hand holding and force, and the core needle is easy to fall off, and achieve the effect of convenient application, low cost and simple manufacture

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment approach 1

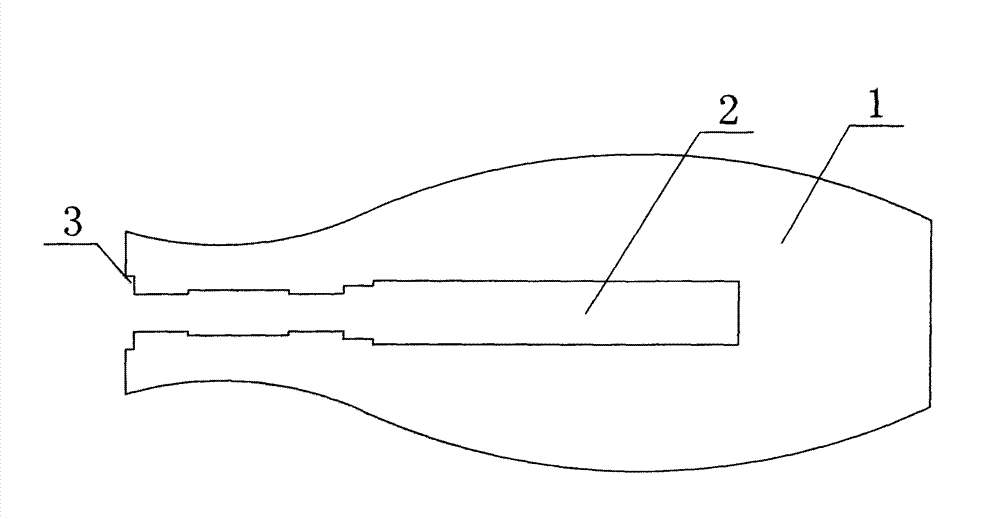

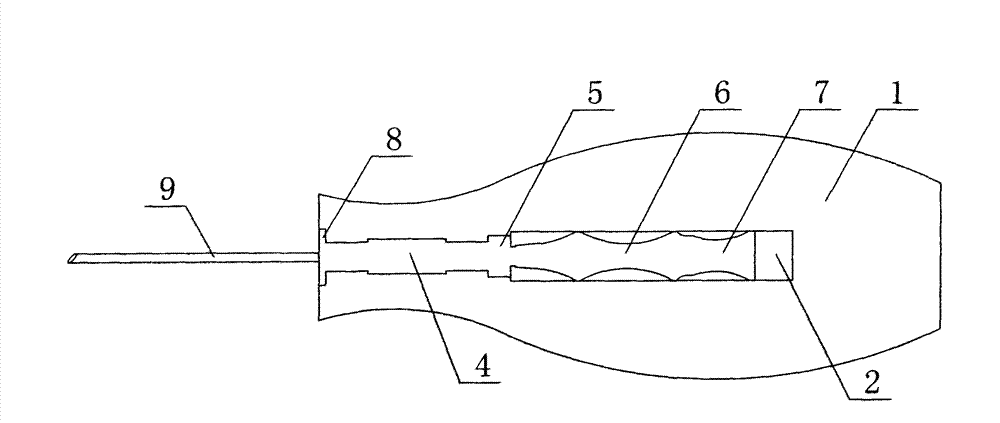

[0020] Specific implementation mode one: as Figure 1-2 As shown, a needle handle cover for bone penetration needles, the needle handle cover 1 is set as an internal hollow structure with an open front end, the needle handle can be set in the hollow cavity 2 inside the needle handle cover, and the length of the cavity 2 is longer than the needle The length of the handle. The shape of the needle handle adjusting screw 4 and the fixing screw 5 placed at the front end of the cavity 2 is consistent with the shape of the needle handle adjusting screw 4 and the fixing screw 5; the shape of the needle body cap 6 placed in the cavity 2 is oval in cross section cylinder, and the long diameter and short diameter of the elliptical cross-section are consistent with the ellipse of the needle body cap 6; the shape of the core needle cap 7 in the cavity 2 and the shape of the cavity 2 longer than the needle handle are both circular in cross section Shaped cylinder, and the diameter of the c...

specific Embodiment approach 2

[0024] Embodiment 2: Different from Embodiment 1, in Embodiment 2, the length of the internal hollow structure of the needle handle cover 1 is 70 mm, wherein the length of the core needle cap is 20 mm, and the length of the needle body cap is 27 mm. The length of the fixed screw part is 3mm, and the length of the adjusting screw part is 20mm.

specific Embodiment approach 3

[0025] Specific embodiment three: different from specific embodiment one, in specific embodiment three, the internal hollow structure length of the needle handle cover 1 is 75 mm, wherein the length of the core needle cap part is 22 mm, and the length of the needle body cap part is 30 mm. The length of the fixed screw part is 3mm, and the length of the adjusting screw part is 20mm.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com