Intelligent control method for preparing limestone slurry

A technology of limestone slurry and intelligent control, applied in separation methods, chemical instruments and methods, and separation of dispersed particles, can solve the problems of no published patent documents, reduce equipment loss and energy waste, ensure stability, and manufacture The effect of pulp density stabilization

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0037] Embodiments of the present invention will be described in detail below in conjunction with the accompanying drawings. It should be emphasized that the embodiments of the present invention are illustrative rather than limiting, so the present invention is not limited to the implementation described in the specific embodiments. For example, all other implementations obtained by those skilled in the art according to the technical solution of the present invention also belong to the protection scope of the present invention.

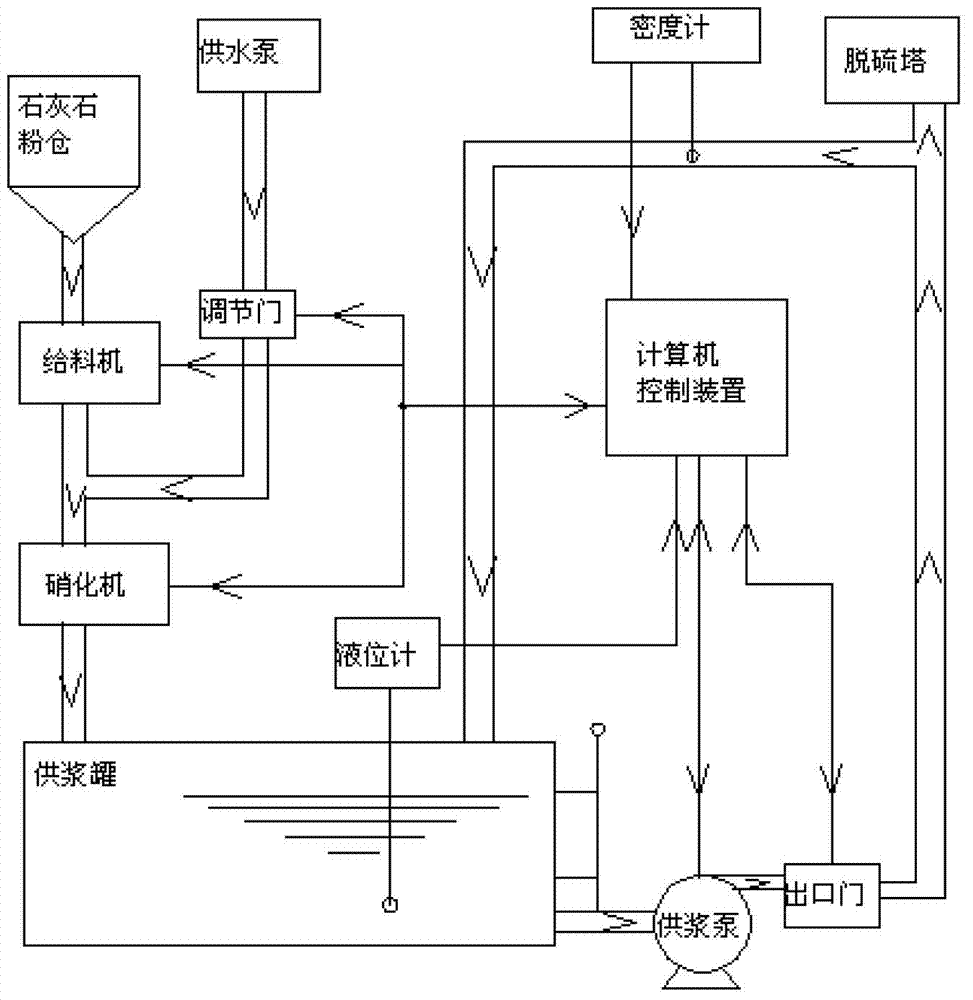

[0038] A kind of limestone slurry preparation intelligent control method, limestone slurry preparation system such as figure 1 As shown, the working steps are as follows:

[0039] (1) The computer control device starts the related equipment in the limestone slurry preparation system in sequence:

[0040] ① Start the water supply pump: the operator starts the operation of the water supply pump through the button of the computer control device;

[004...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com