Nano-solution for tiles to remove formaldehyde and production process of formaldehyde-removing tiles

A ceramic tile and nanotechnology, applied in other chemical processes, dispersed particle separation, chemical instruments and methods, etc., can solve the problems of activated carbon being easily oxidized, high cost of tile manufacturers, and limited ability to absorb formaldehyde, etc., to achieve long-term removal Formaldehyde, low promotion cost, strong formaldehyde adsorption effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

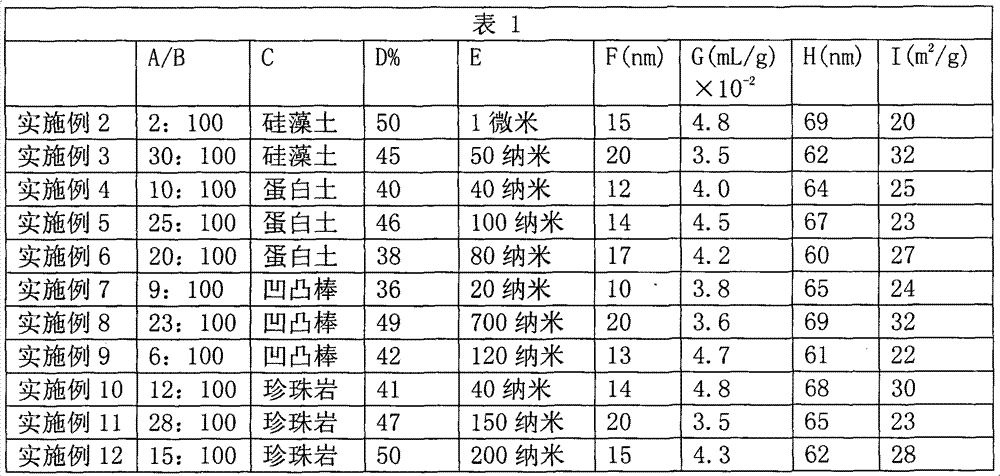

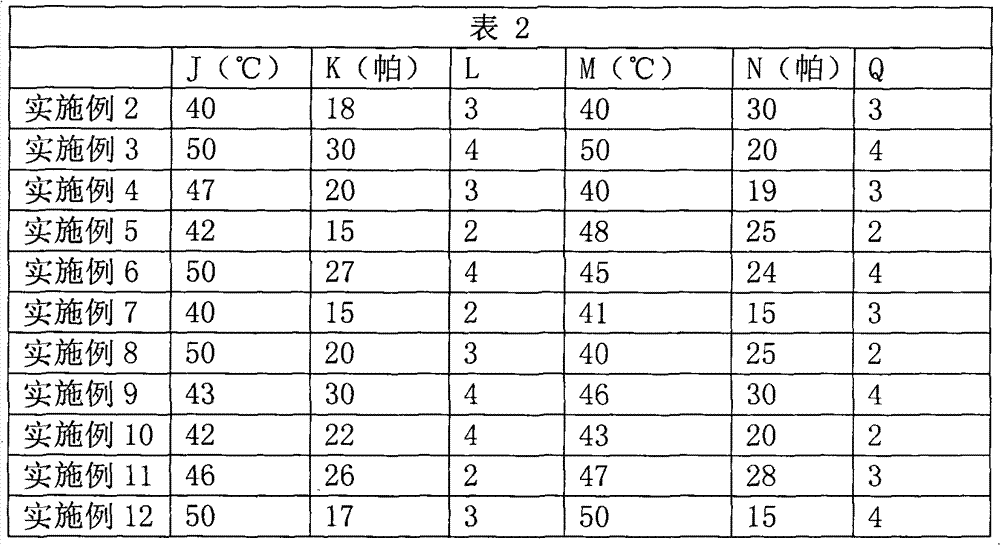

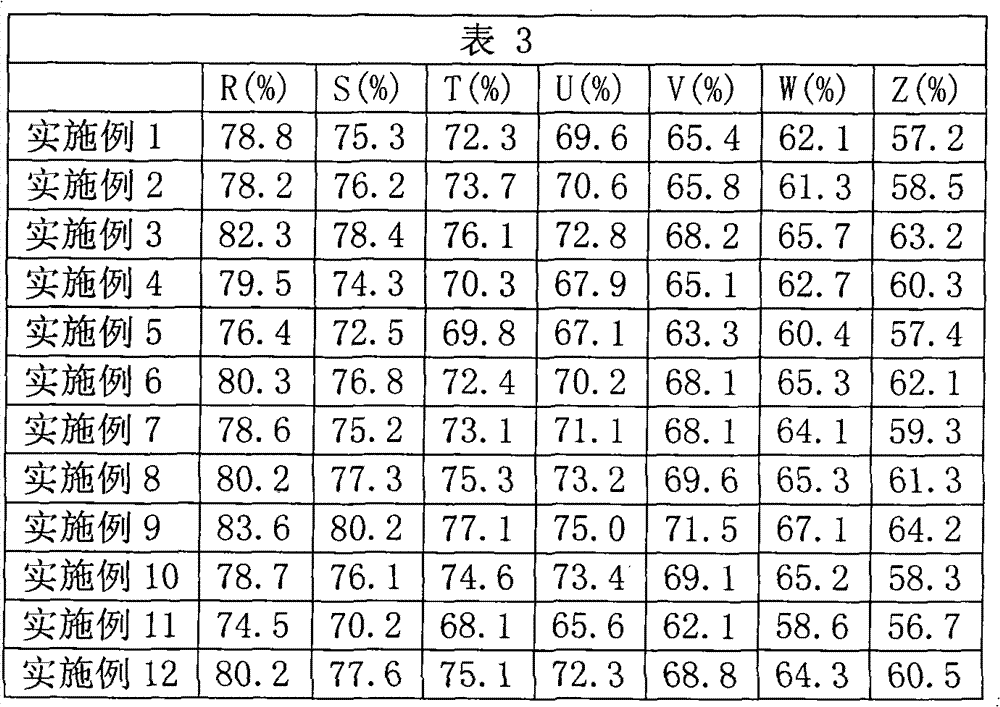

Embodiment 1

[0025] In this embodiment, the formaldehyde-removing nano-liquid for tiles includes a porous mineral-loaded titanium dioxide composite material and a tile antifouling liquid, and the porous mineral-loaded titanium dioxide composite material is added to the tile antifouling liquid to form a mixture. The mass ratio of porous mineral-loaded titanium dioxide composite material to tile antifouling liquid is 2:100; It is referred to as commodity base liquid and commodity surface liquid), which can be purchased from the market, and will not be described in detail here. The porous mineral loaded titanium dioxide composite material is composed of porous mineral and titanium dioxide, and the porous mineral is diatomaceous earth. The mass fraction of titanium dioxide in the porous mineral-loaded titanium dioxide composite material is 36%. The particle size of the porous mineral-loaded titanium dioxide composite material is 50 nanometers. In the porous mineral-supported titanium dioxide...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com