Exhaust device with deflection plate

A technology of exhaust device and deflection plate, which can be applied to home appliances, cleaning methods and appliances, and dust removal, etc. It can solve the problems of inability to completely block harmful gas leakage, unstable vortex, etc., to reduce large backflow, reduce The effect of leakage

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

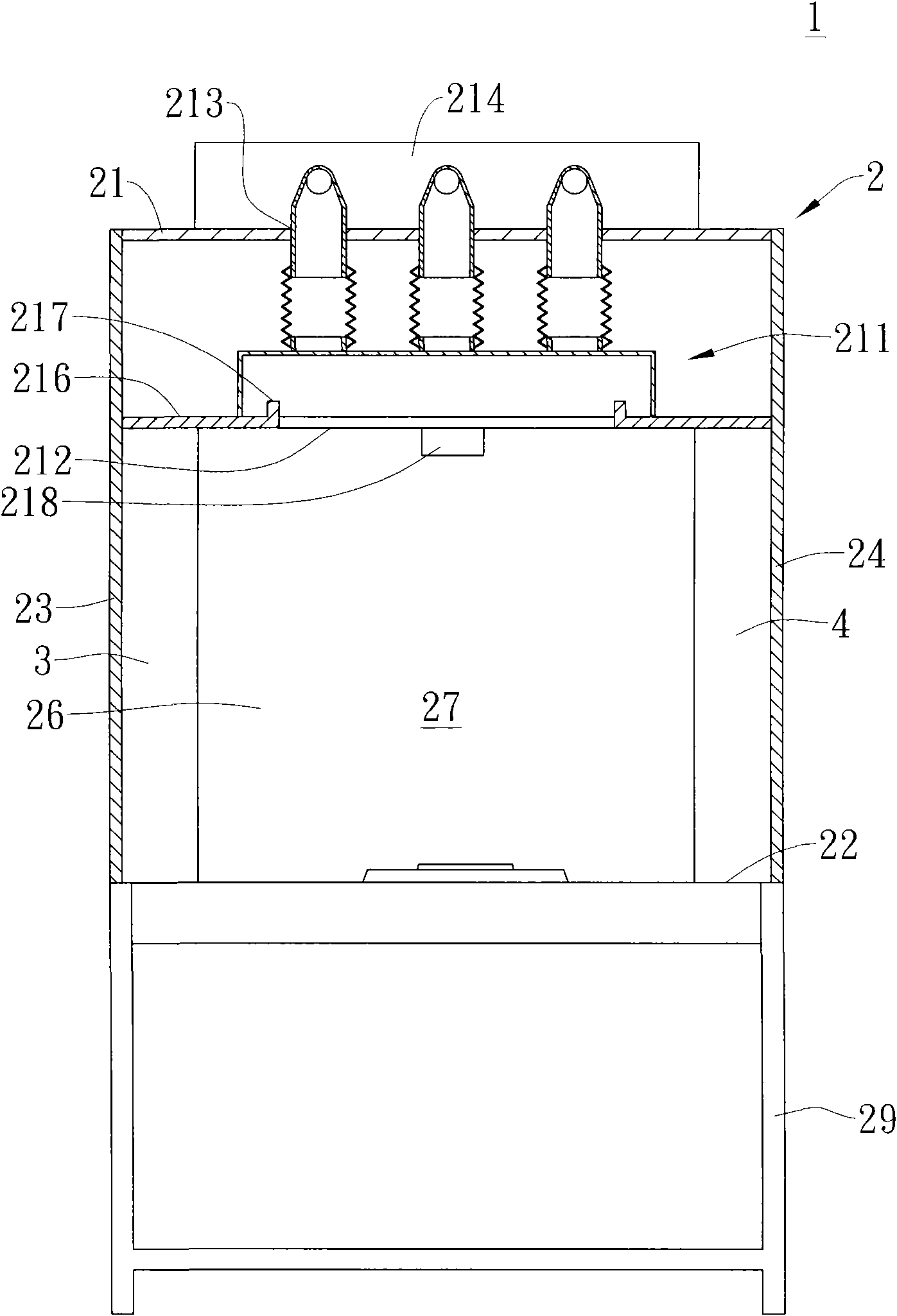

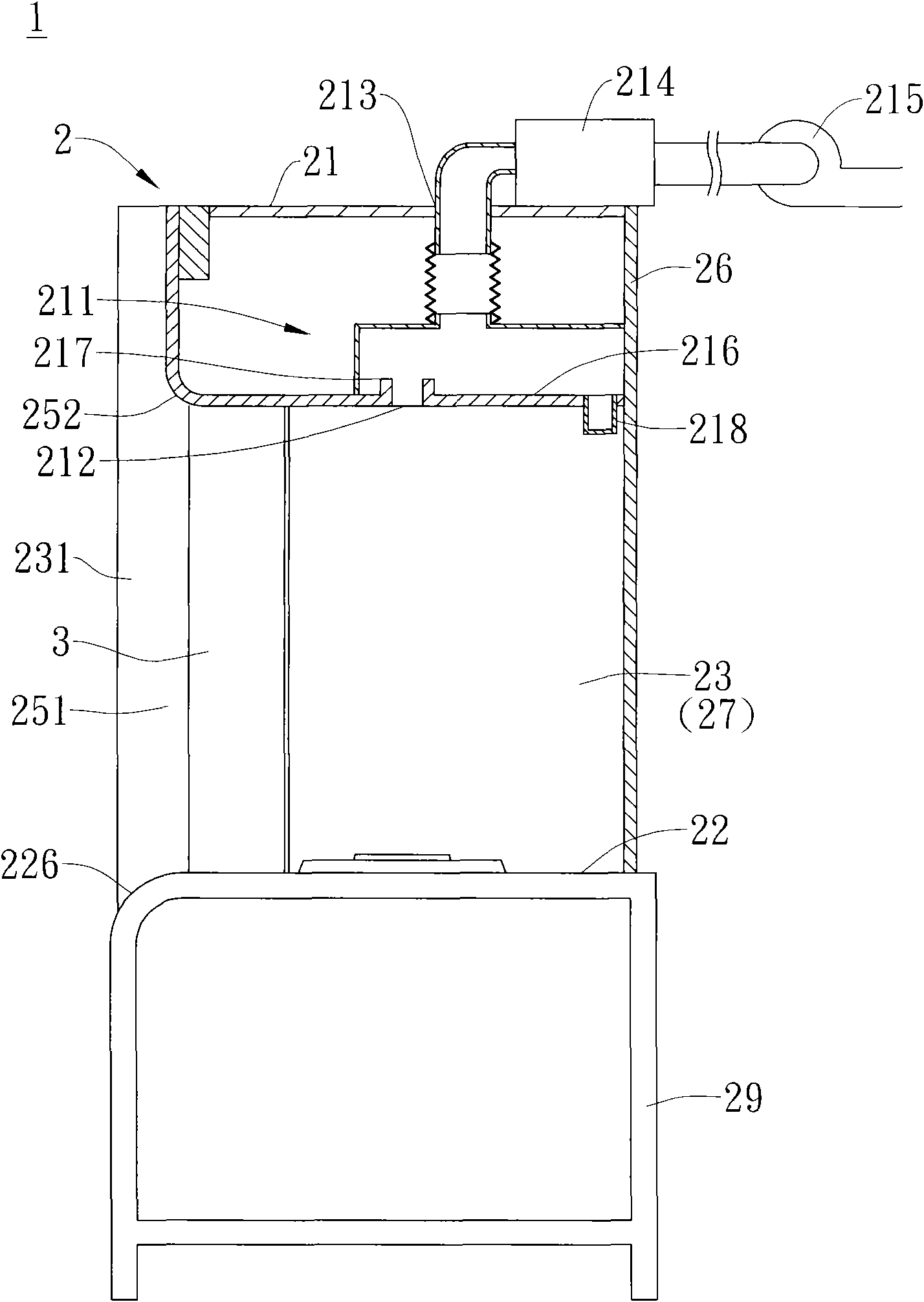

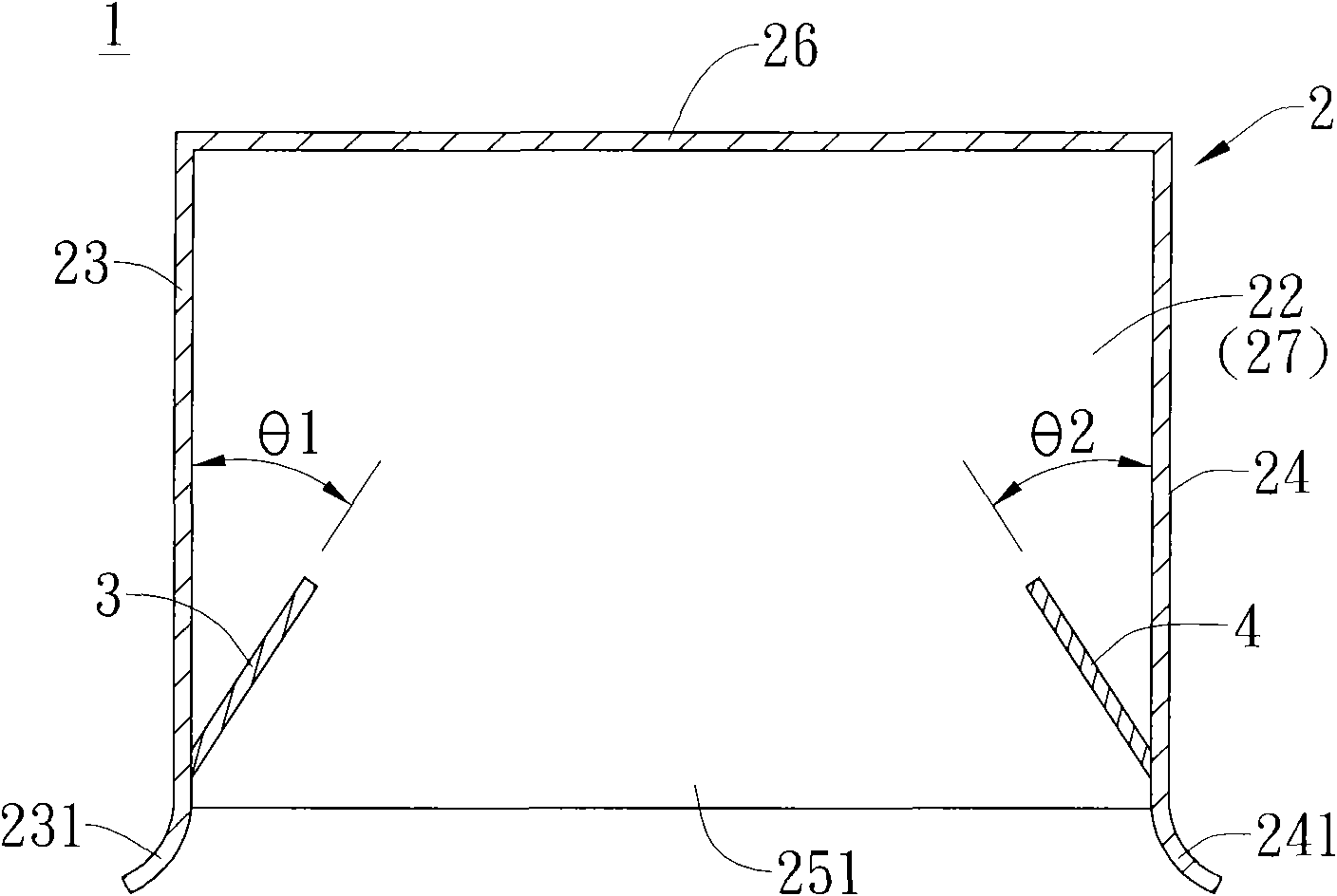

[0051] Such as Figure 1-3 As shown, it is the first embodiment of the exhaust device 1 with deflecting plates of the present invention, which includes an operation cabinet 2 , a left deflecting plate 3 and a right deflecting plate 4 .

[0052] The operating cabinet 2 is roughly in the shape of a cuboid, and a locker 29 with legs is provided below it to support the operating cabinet 2 upwards and store objects. The operating cabinet 2 includes a suction hood 21, a bottom plate 22, and a left side plate 23. A right side panel 24 and a rear panel 26. After the panels are combined, an accommodating space 27 is formed inside the operation cabinet 2, and an opening 251 is formed under the front end of the suction hood 21. And the bottom of the front end of the suction hood 21 is provided with an arc-shaped first guide portion 252, and the top of the front end of the base plate 22 is provided with an arc-shaped second guide portion 226, and the left side plate 23 in the operation ca...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com