Annular part fixture

A technology of ring parts and fixtures, which is applied in the direction of manufacturing tools, forging/pressing/hammer devices, forging/pressing/hammering machinery, etc., which can solve the problems of poor firmness of clamping workpieces, low strength of claws, and easy falling off of workpieces, etc. , to achieve the effects of small clamping force, high clamping rigidity and reduced residual stress

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0017] In order to make the object, technical solution and advantages of the present invention clearer, the present invention will be further described in detail in conjunction with the accompanying drawings.

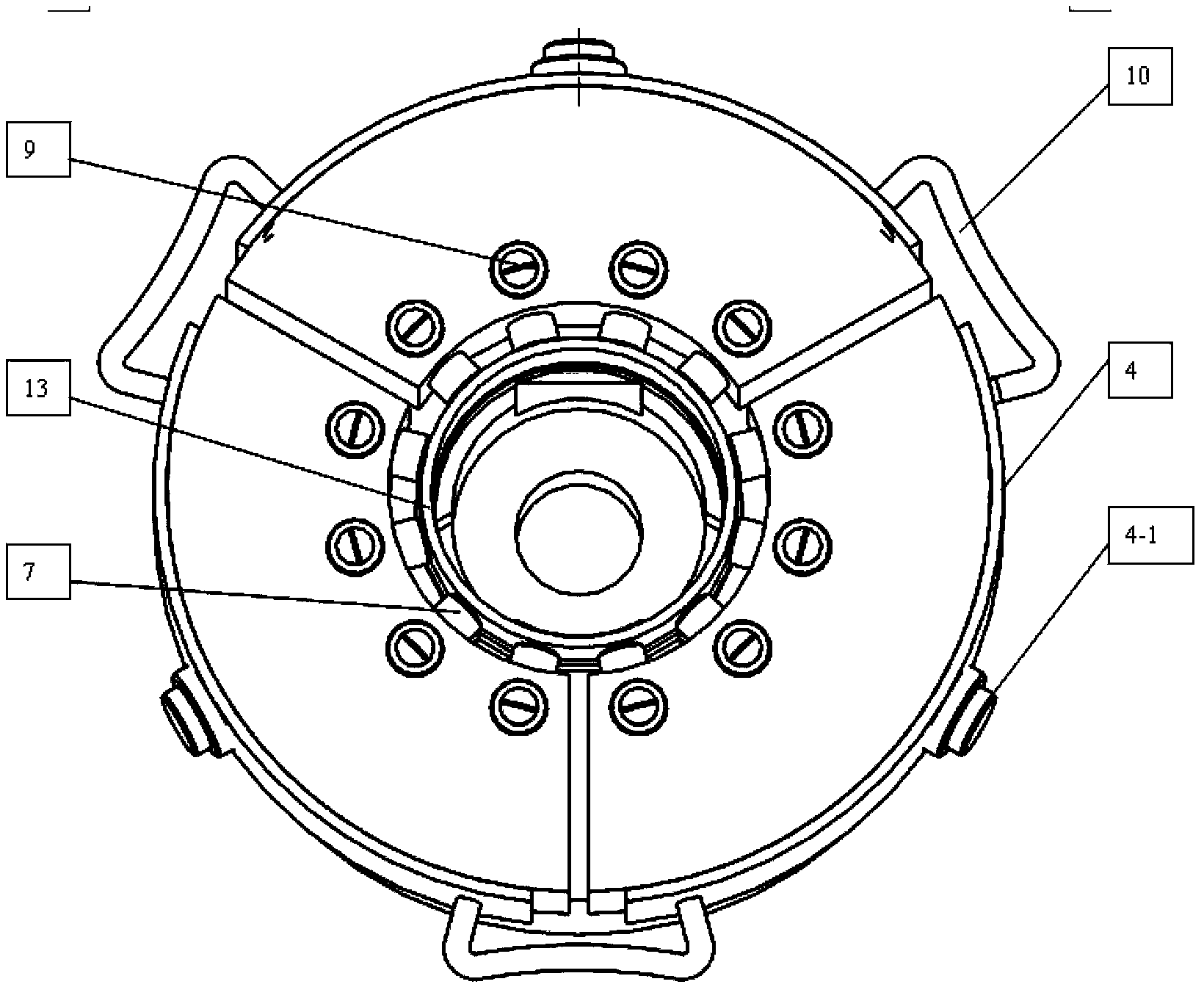

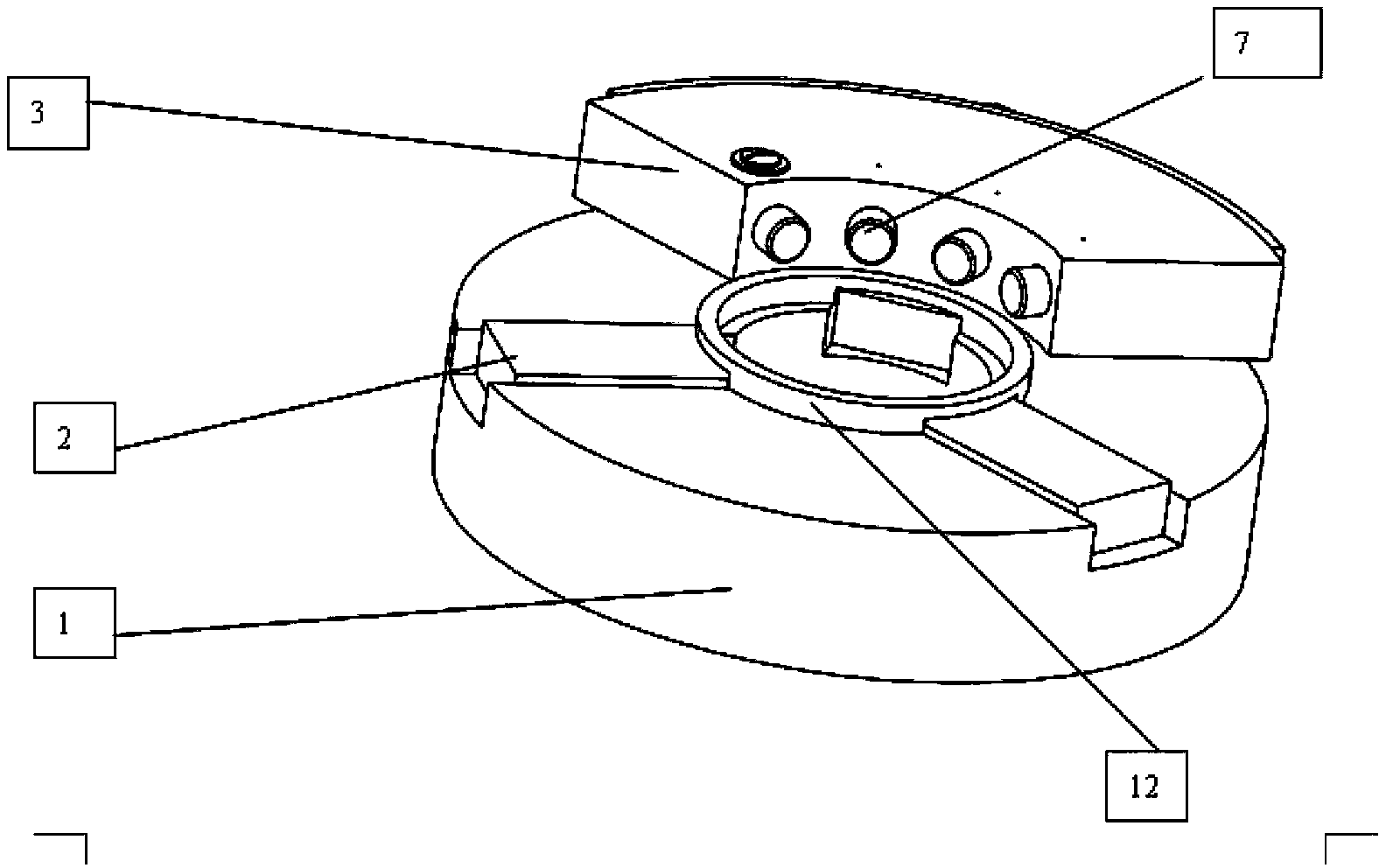

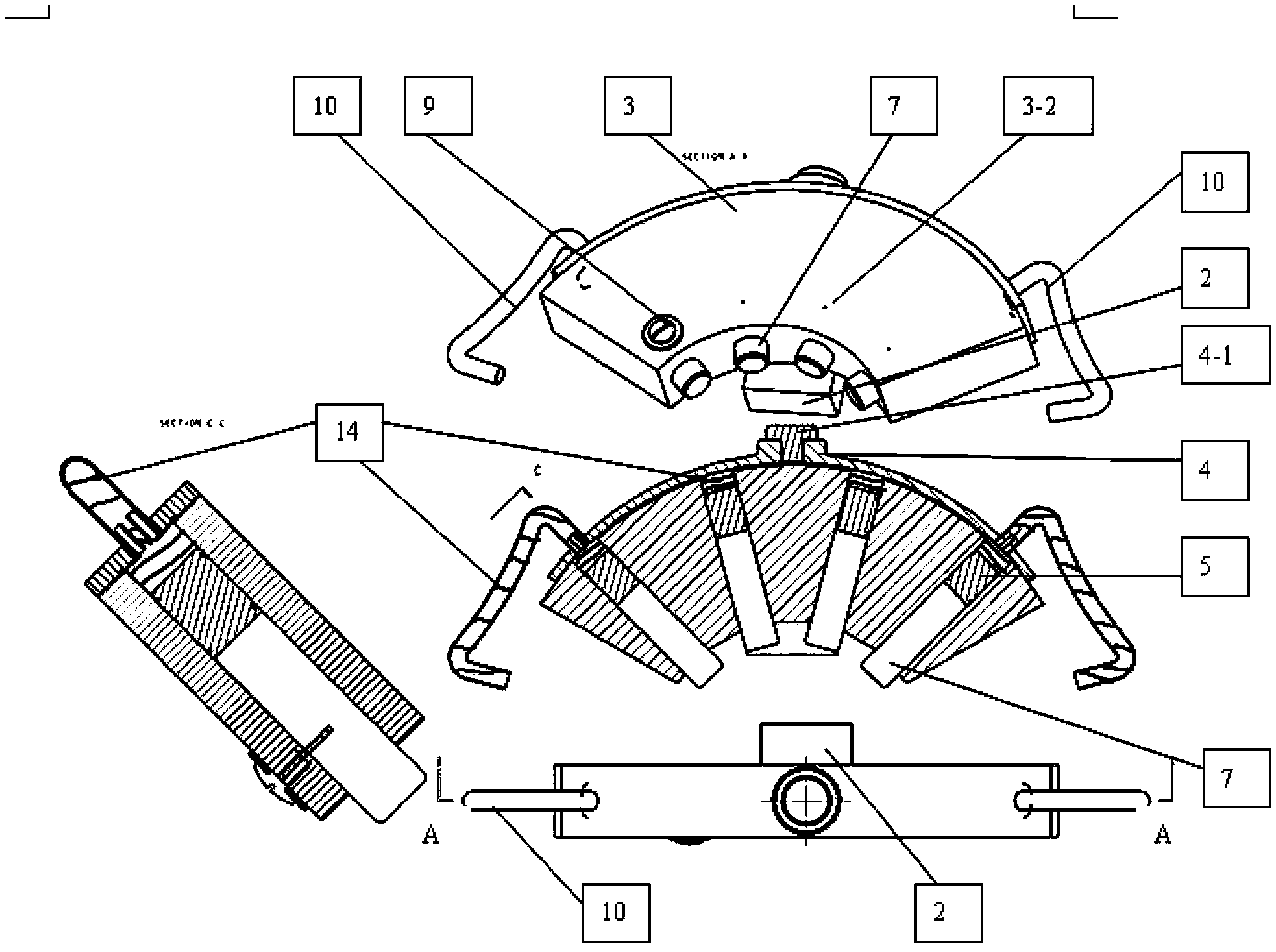

[0018] Such as figure 1 , figure 2 The shown annular part fixture of the present invention includes a three-jaw wedge power chuck seat 1, a base jaw 2, a jaw hydraulic seat 3, an arc-shaped sealing seat 4, a jaw 7, a hydraulic hose 10, and an end positioning ring 12, Ring workpiece 13. On the jaw hydraulic seat 3, several jaw base holes 3-1 are evenly distributed radially with the center of the three-jaw wedge power chuck seat 1 as the axis. Jaw base hole 3-1 is integrally slidably matched with jaw piston 5, the front end of jaw piston 5 is in contact with jaw 7, the rear end of jaw piston 5 is in contact with hydraulic oil 14, and jaw piston 5 is in jaw base hole 3-1 Under the action of internal hydraulic oil, the jaws 7 are pushed to move radially along the center...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com