Clamp for machining drilling and milling joint surface of engine cylinder head

A technology of engine cylinder head and joint surface, which is applied in the direction of manufacturing tools, metal processing equipment, metal processing machinery parts, etc., can solve the problems of system deviation, time-consuming, and the decline of cylinder head yield, so as to reduce the excessive flatness , easy operation and simple structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

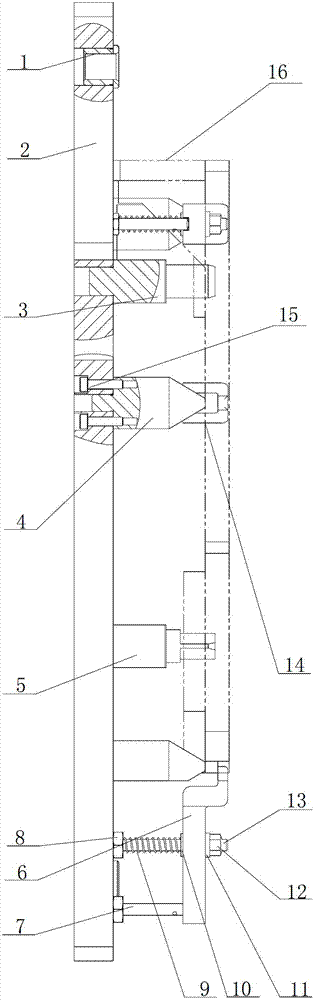

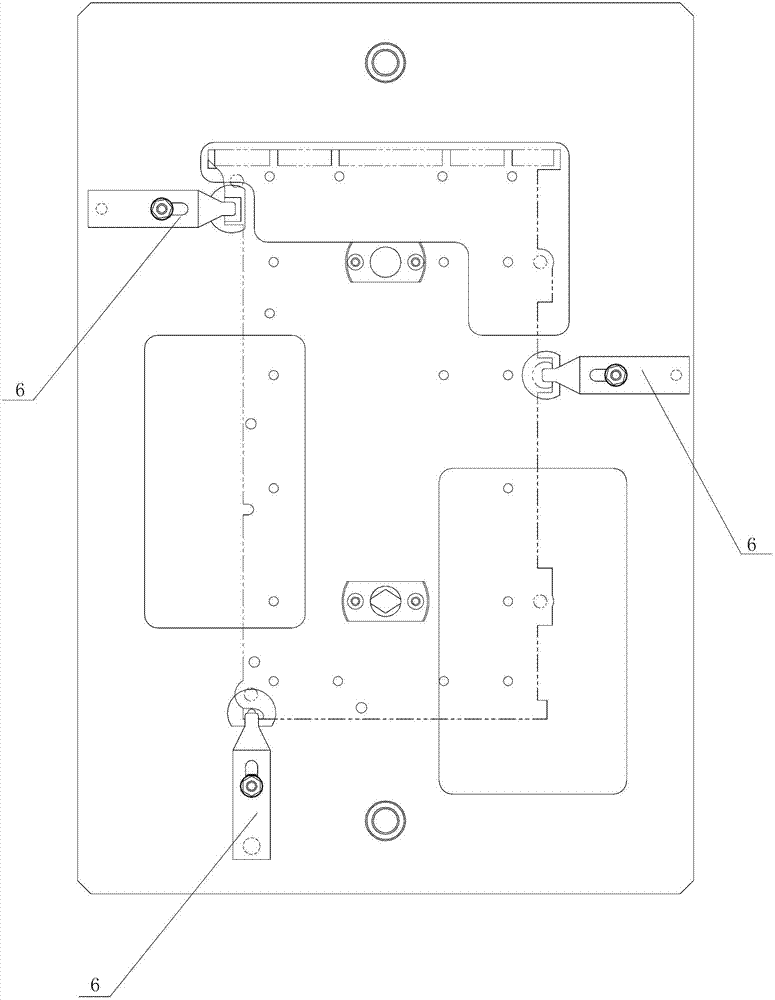

[0015] Such as figure 1 with figure 2 Shown is a clamp for machining the joint surface of engine cylinder head drilling and milling according to the present invention, which includes a bottom plate 2, a pressing mechanism provided on the bottom plate 2 for pressing the cylinder head 16 and a clamping mechanism provided on the bottom plate 2 The positioning mechanism for positioning the cylinder head 16 includes a plurality of supporting blocks 4 arranged at specific positions on the bottom plate 2. The cylinder head 16 is placed on the positioning plane formed by the supporting blocks 4, and the upper surface of the supporting block 4 Grinding in the same plane to ensure that the flatness of the positioning surface meets the technical requirements for adjustment of the processing position of the cylinder head 16. The size of the bottom plate 2 is equivalent to the size of the cylinder head 16. Compared with the prior art, this clamp uses the supporting block 4 instead of the ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com