Parameter optimization method for six-degree of freedom parallel mechanism for modal space control

A modal space and optimization method technology, applied in the direction of program control manipulators, manipulators, manufacturing tools, etc., can solve the problem that modal space decoupling control is still applicable

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

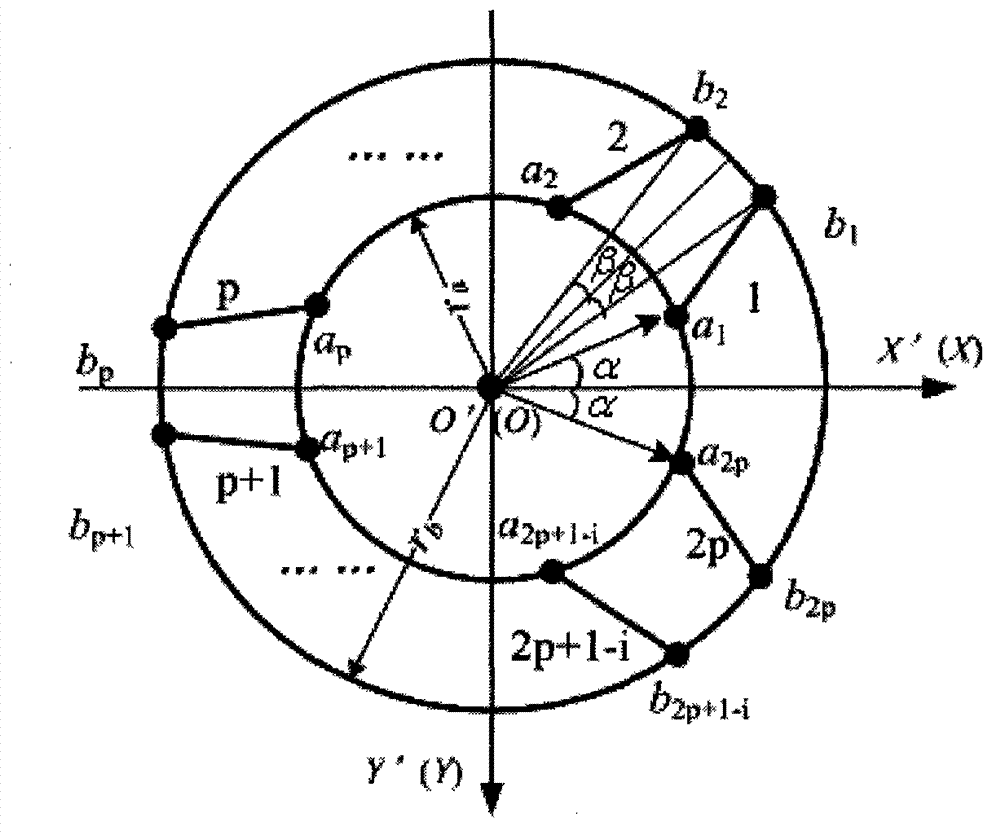

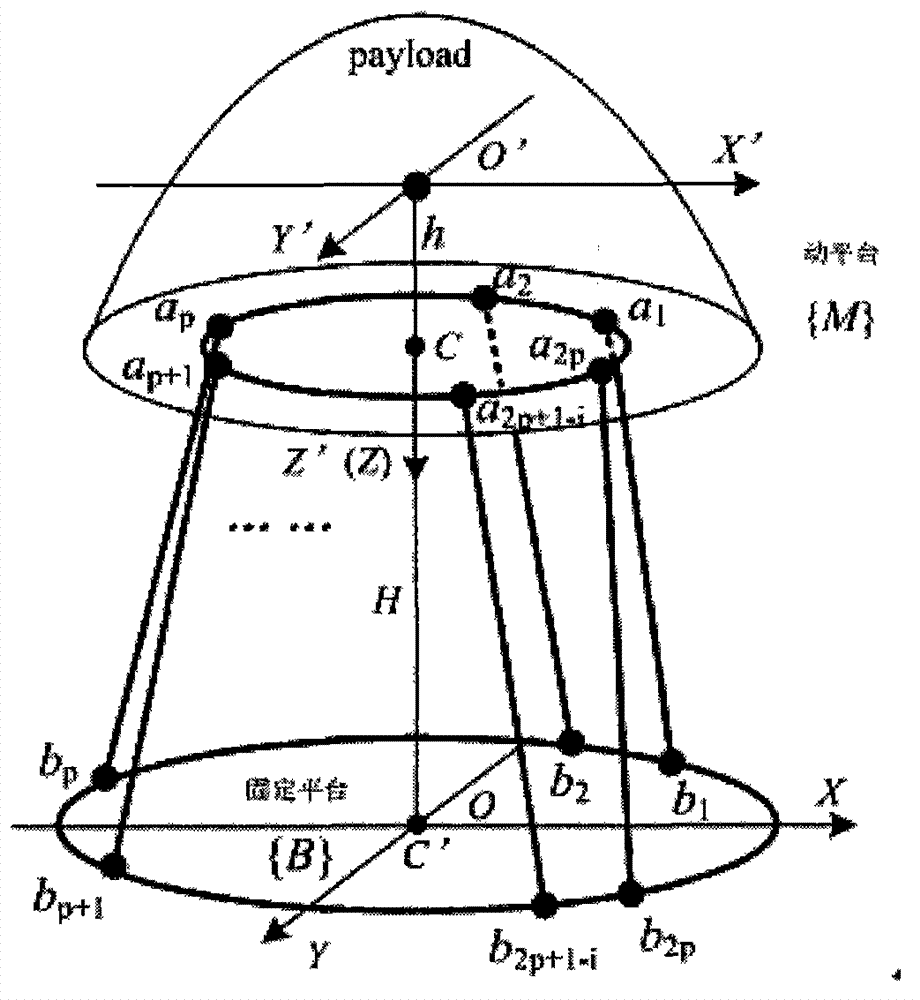

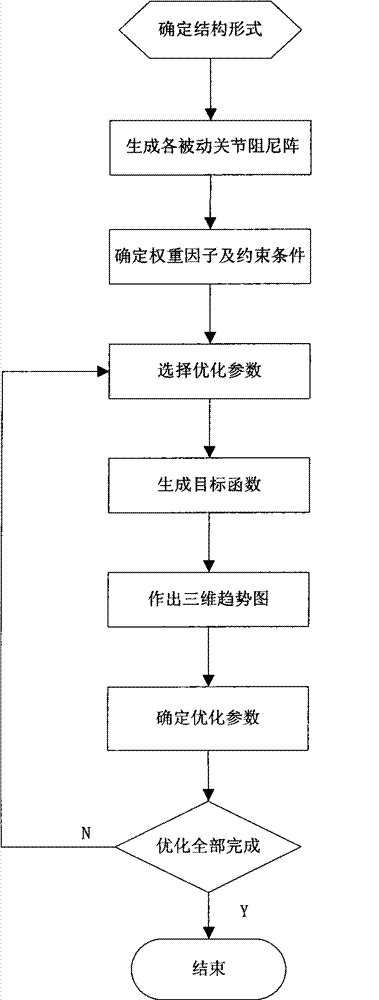

[0112] Step 1: Determine System Configuration

[0113] The configuration of the system to be optimized is the 6-leg UCU (double-end universal joint or Hooke hinge), p=3, and its structural diagram is shown in the attached image 3 As shown, the schematic diagram of a single outrigger is attached Figure 4 shown.

[0114] Step 2: Generate the damping matrix of each passive joint.

[0115] Lower hinge damping array:

[0116] Direction 1: C cd 1 = diag ( C cd 1 x C ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com