Coke oven collecting main pressure intelligent decoupling control method

A technology of collecting pipe pressure and decoupling control, applied in the direction of adaptive control, general control system, control/regulation system, etc. Control, eliminate coupling effects, reduce production costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

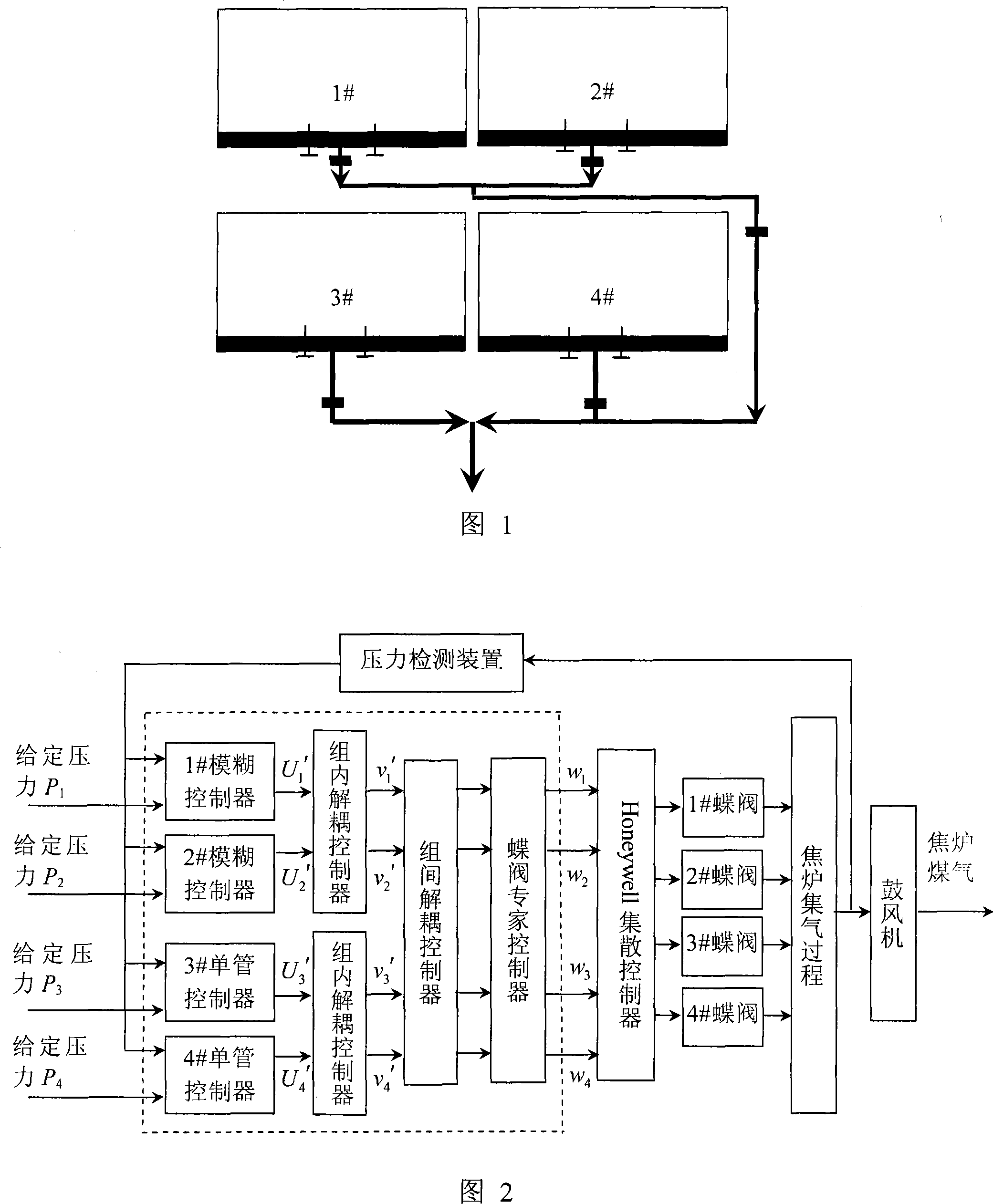

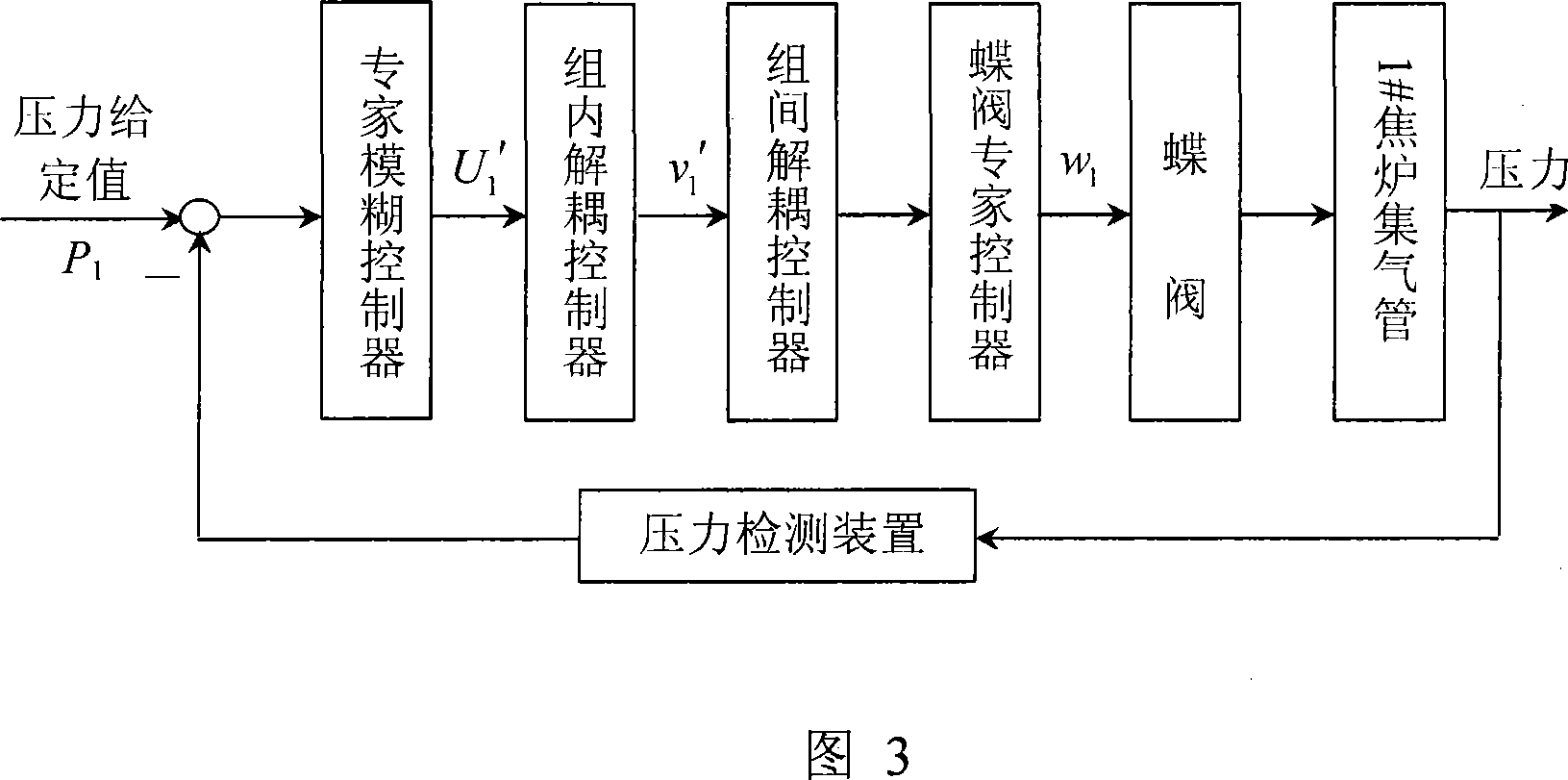

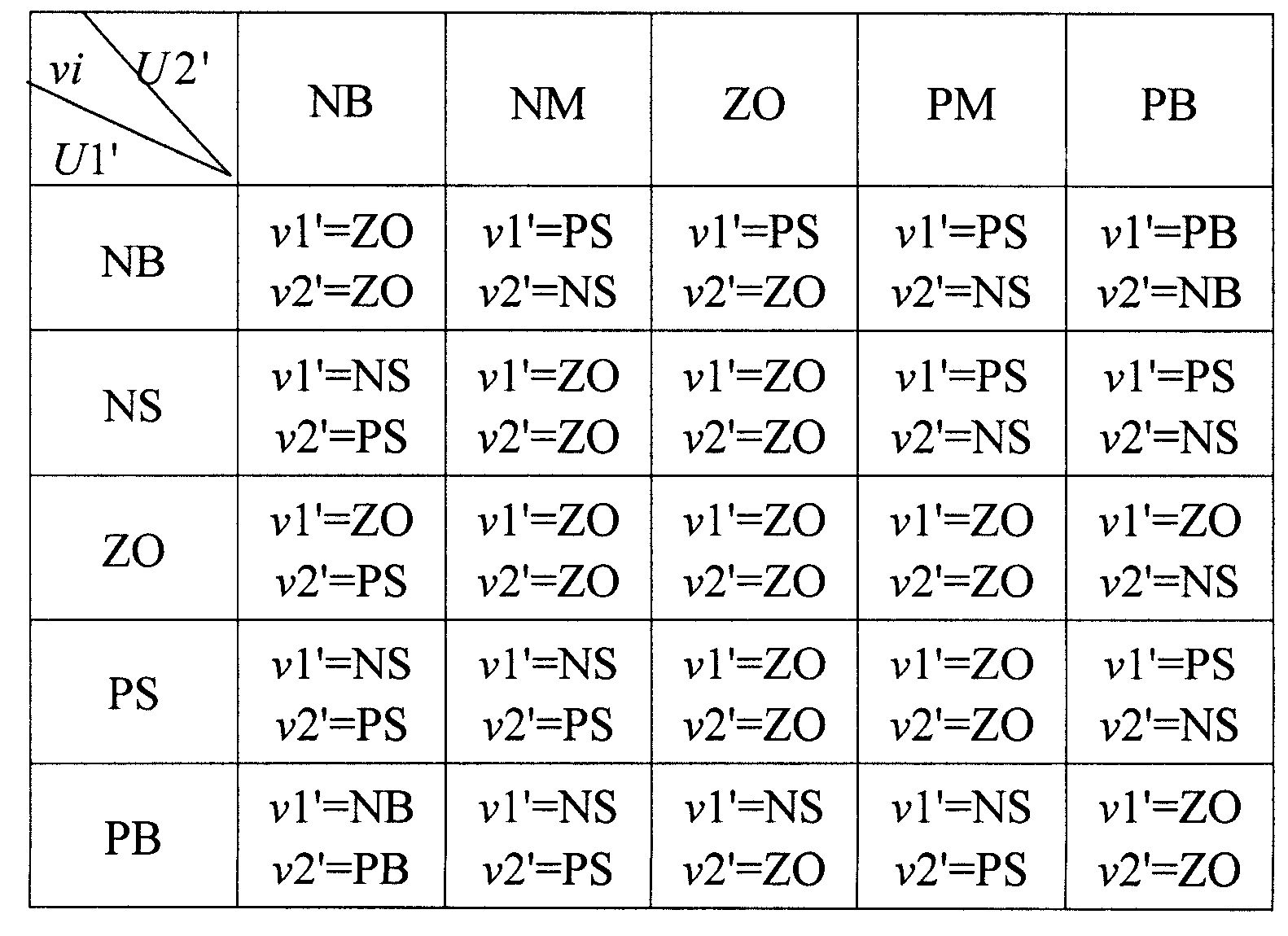

[0019] The intelligent decoupling control process of coke oven gas collecting pipe pressure in the present invention is as follows: In the present invention, there are 4 coke ovens No. 1-4. First detect the actual pressure P of the coke oven gas collector of No. 1-4 1 '-P 4 ’, and then the pressure P of each coke oven gas collector 1 '-P 4 ’ and pressure given value P 1 -P 4 The deviation and the deviation change rate are used as the input of each coke oven gas collecting pipe pressure fuzzy controller, and the control increment U of each single output is calculated by each coke oven gas collecting pipe fuzzy controller 1 '-U 4 ’, and then use the decoupled controller pair within the group to control the increment U 1 '-U 4 ′ Decoupling within the group to obtain the correction value v of the control increment 1 '-v 4 ′, on this basis, use the inter-group intelligent decoupling controller to compensate the control correction calculated by the intra-group intelligent d...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com