Method for producing carbon fiber bicycle frame

A production method and carbon fiber technology, applied in the field of carbon fiber bicycle frame production, can solve the problems that epoxy resin is not easy to be evenly distributed, pinholes are easy to be generated, and shear strength is reduced, so as to achieve uniform distribution of epoxy resin and reduce The problem of pinholes and fine holes, the effect of improving interlayer bonding

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

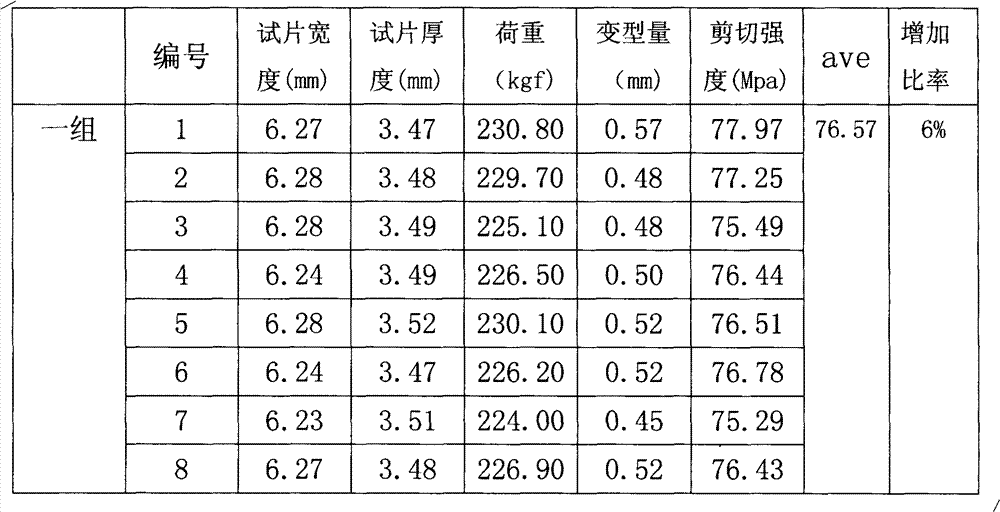

Examples

Embodiment Construction

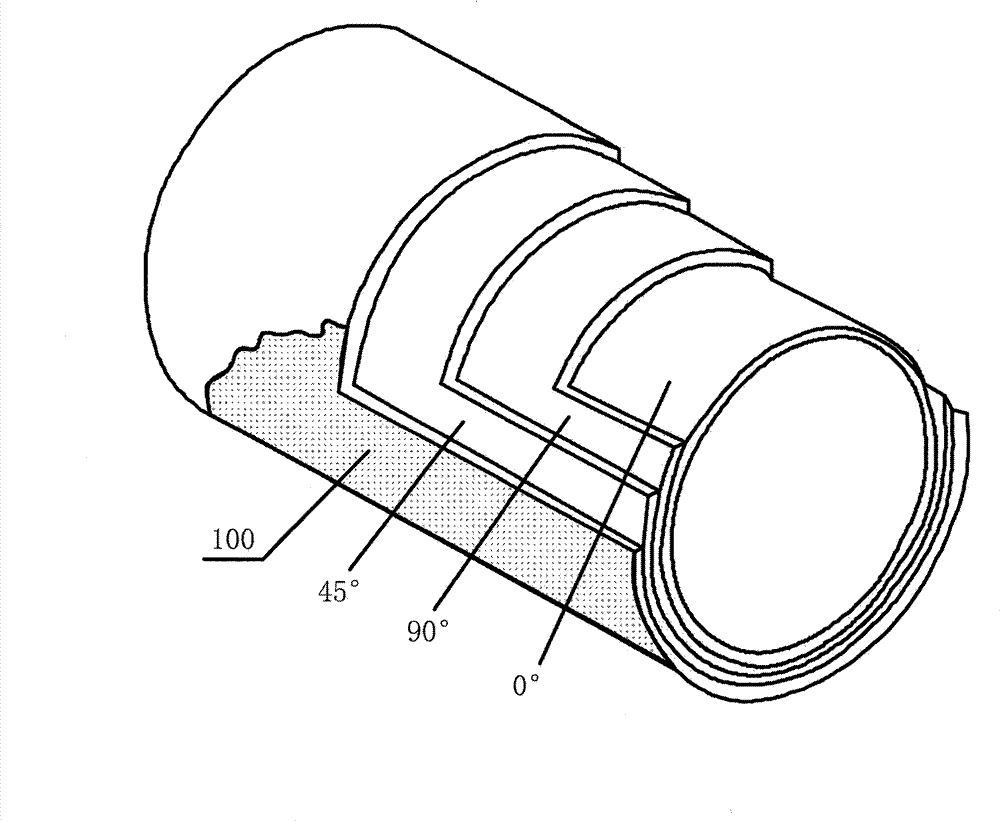

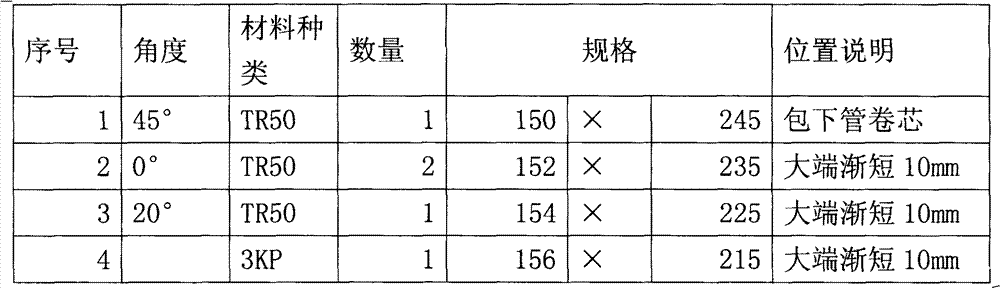

[0018] The present invention will be further described below in conjunction with the accompanying drawings and preferred embodiments.

[0019] Carbon fiber, as the name suggests, not only has the inherent intrinsic characteristics of carbon materials, but also has the softness and processability of textile fibers. It is a new generation of reinforcing fibers. Compared with traditional glass fiber (GF), the Young's modulus is more than 3 times; compared with Kevlar fiber (KF-49), not only the Young's modulus is about 2 times, but also in organic solvents Insoluble and non-swelling in acid and alkali, with outstanding corrosion resistance. Some scholars soaked PAN-based CF in a strong alkali NaOH solution in 1981. More than 30 years have passed, and it still maintains the fiber form. At present, carbon fiber has high strength and light weight, which is an ideal material for making bicycle frames. The invention is a manufacturing method of a carbon fiber bicycle frame, combined...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com