Novel packing machine

A new type of packaging and rack technology, applied in the direction of packaging, transport packaging, multiple packages, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

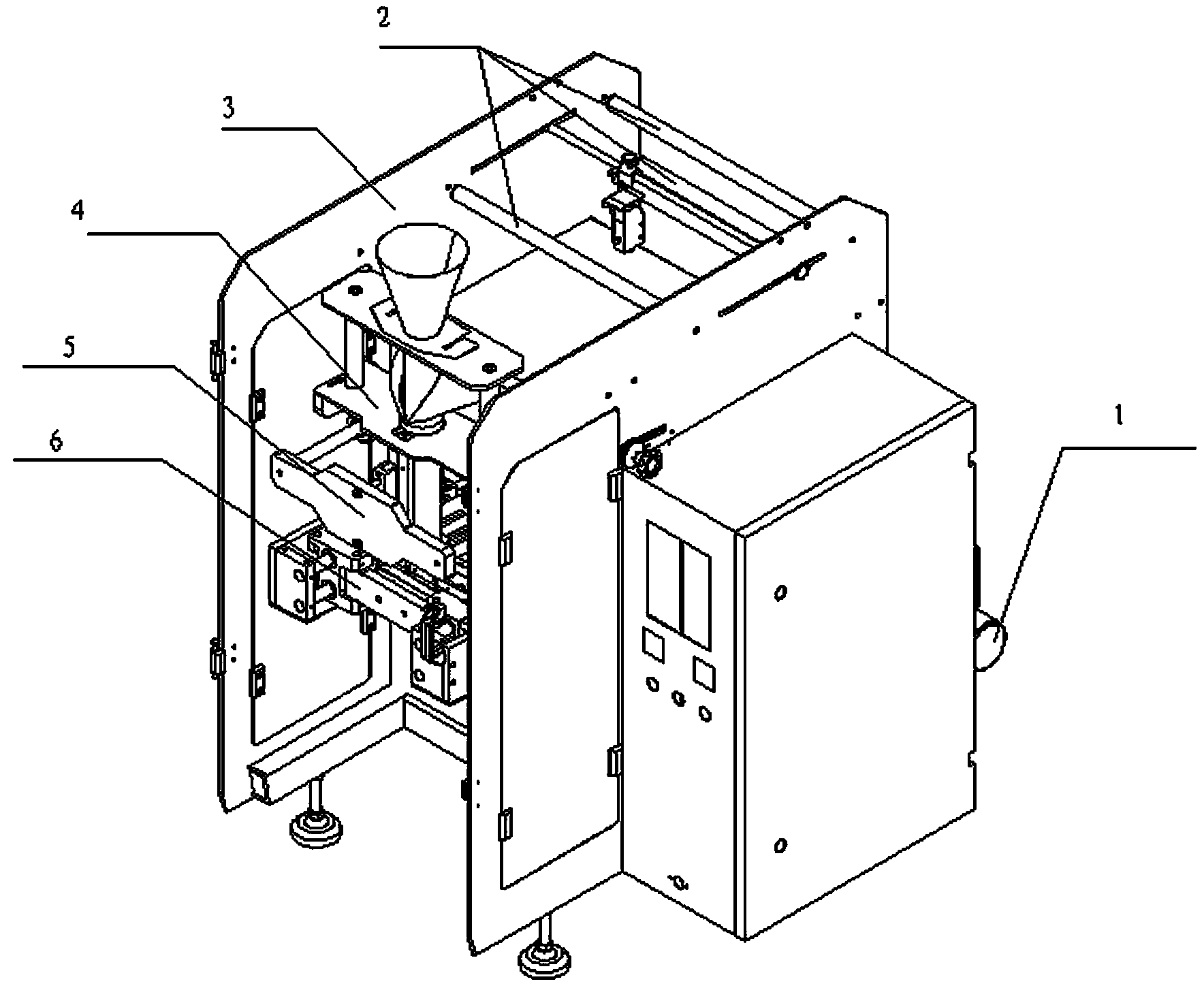

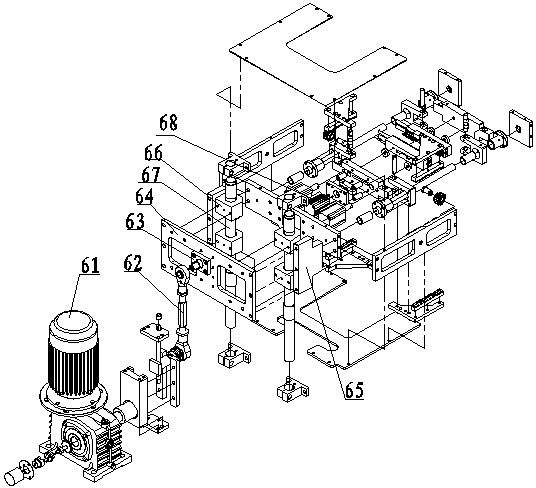

[0033] Such as figure 1 , figure 2 and image 3 As shown, a new type of packaging machine includes a frame 3, a film-moving mechanism 2, a bag-forming mechanism 4, a vertical sealing mechanism 5 and a horizontal sealing mechanism 6. It is characterized in that: according to the direction of film movement, the film-moving mechanism 2 , the bag forming mechanism 4, the longitudinal sealing mechanism 5 and the horizontal sealing mechanism 6 are installed on the frame 3, the bag forming mechanism 4 is installed above the vertical sealing mechanism 5, and the vertical sealing mechanism 5 is installed above the horizontal sealing mechanism 6, The horizontal sealing mechanism 6 includes a horizontal sealing device 68 and a lifting mechanism. The lifting mechanism includes an upper and lower horizontal sealing connecting plate 64, a guide shaft 67 fixed on the upper and lower horizontal sealing connecting plate 64, and a horizontal sealing seat fixed on the guiding shaft 67. Plate...

Embodiment 2

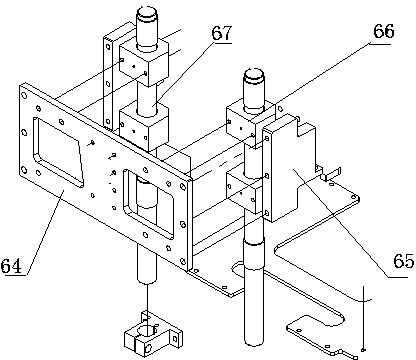

[0035] Such as Figure 4 As shown, the preferred horizontal sealing device 68 of this embodiment on the basis of Embodiment 1 includes a front knife seat fixing seat 685, a rear knife seat fixing seat 6812, and a heat insulation pad 686 arranged between the front and rear knife seat fixing seats. , The front knife seat 684 and the rear knife seat 683 arranged between the heat insulating pads 686, the front knife seat 684, the rear knife seat 683, the front knife seat fixing seat 685, and the rear knife seat fixing seat 6812 pass through the horizontal sealing guide shaft 11 connected, the two sides of the front knife seat fixing seat 685 and the rear knife seat fixing seat 6812 are provided with sliding blocks 6810, the sliding blocks 6810 are connected to the front and rear connecting plates through the pin shaft 687, and the sliding block 6810 is equipped with a linear sliding film , the sliding block 6810 is equipped with a rack fixing plate 682 on the left and right, front...

Embodiment 3

[0037] Such as Figure 4 and Figure 5 As shown, in this embodiment, on the basis of Embodiment 2, the horizontal seal guide shaft 11 is a horizontal seal single guide shaft, and the horizontal seal single guide shaft is provided with a linear sliding bearing 12, which is mainly supported by two sets of upper and lower sliders 13 Fix the linear sliding bearing 12 to make the single horizontal seal guide shaft slide smoothly, and it is mainly used in short tool holders and narrow tool holders, and under light load conditions.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com