Shuttle vehicle

A shuttle car and frame technology, which is applied in the field of shuttle cars, can solve the problems of difficult driving skills for forklift drivers, reduce the efficiency of cargo access, and reduce the utilization rate of warehouses, so as to reduce the cost of personnel training, improve space utilization, Effect of reducing cargo damage rate

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

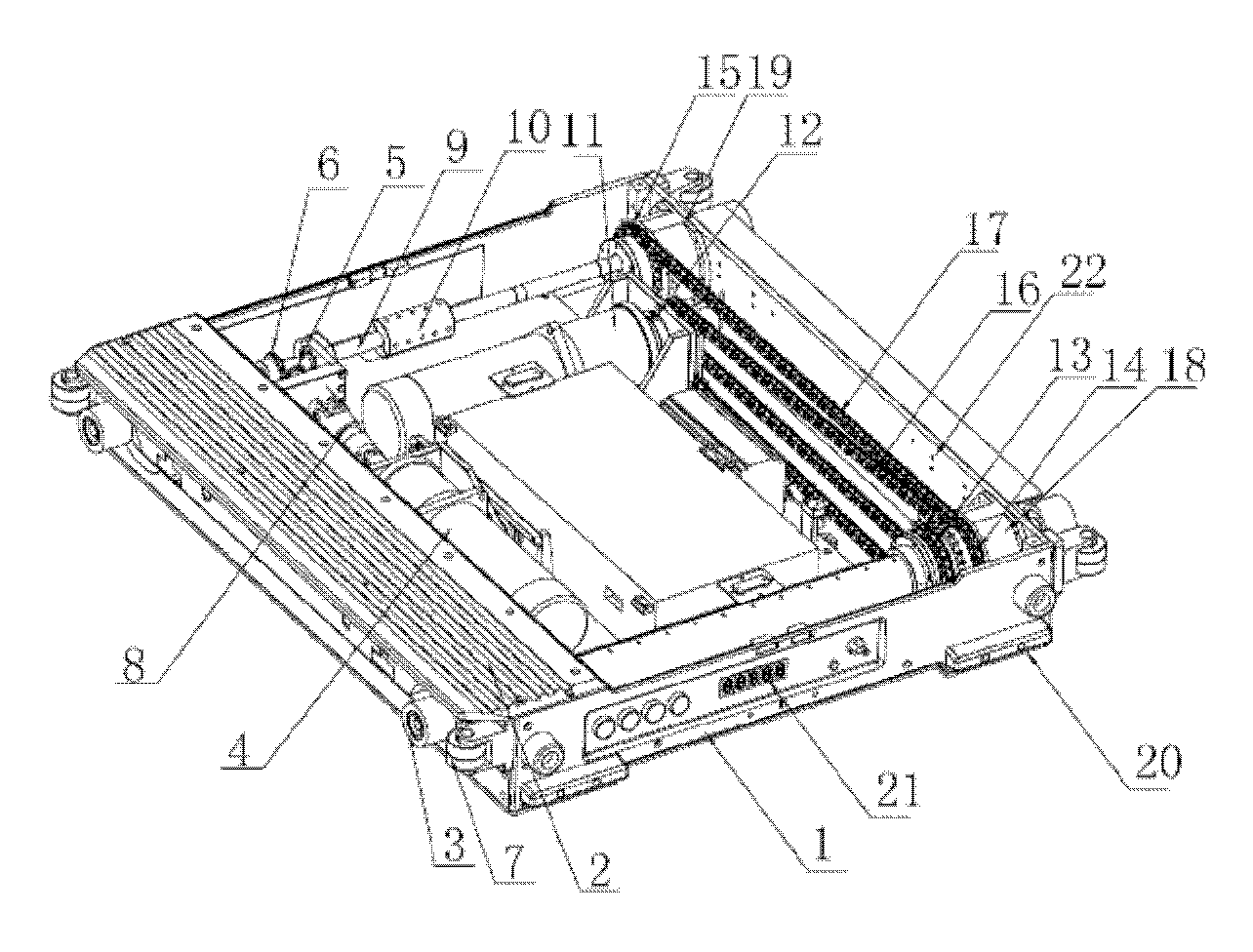

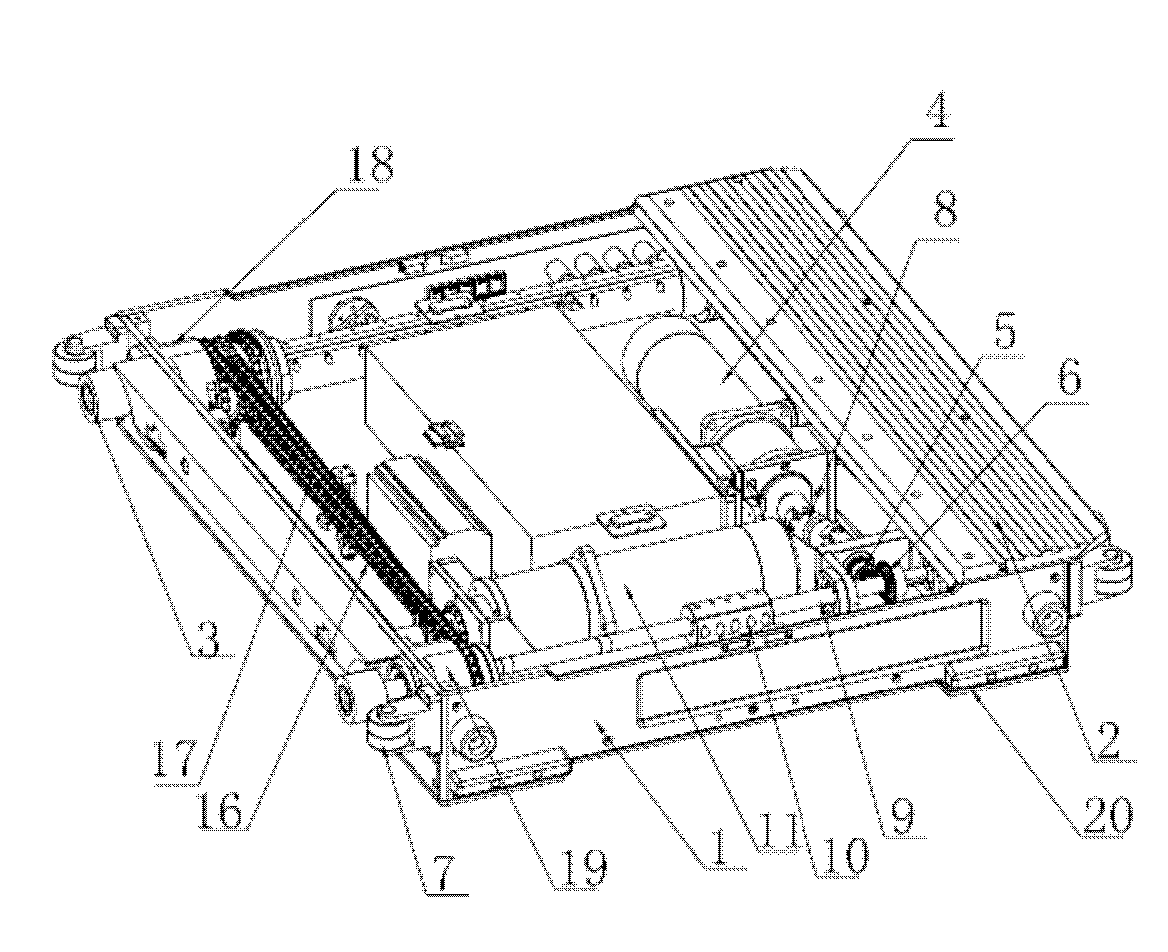

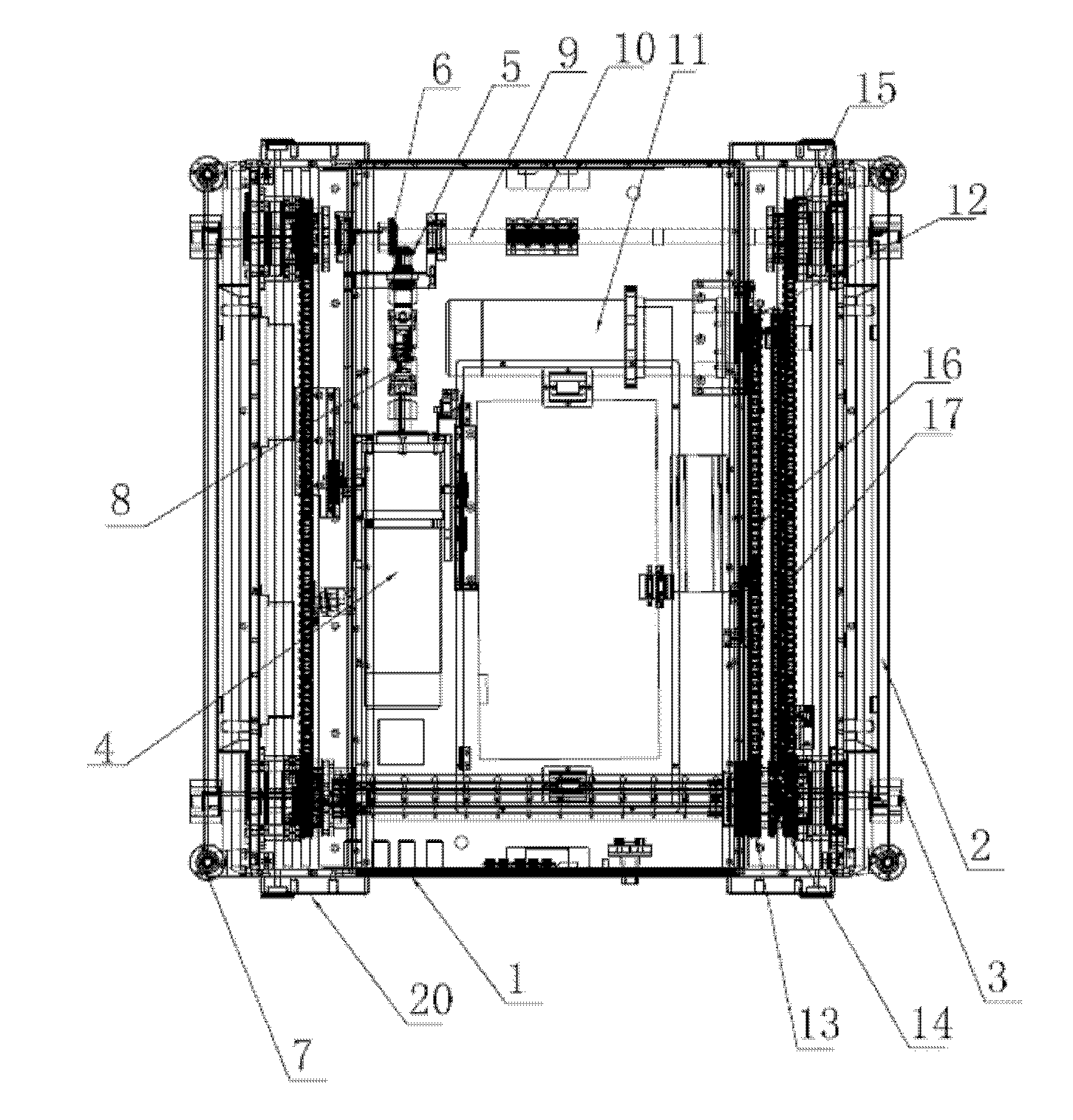

[0019] Embodiment: A shuttle car, including a vehicle frame 1, a supporting plate 2, a lifting mechanism, a driving mechanism and a wheel 3. Based on the direction of use, the supporting plate 2 can be slid and positioned above the vehicle frame 1 in the longitudinal direction, and the lifting mechanism and the driving mechanism Fixed in the vehicle frame 1, at least four wheels 3 can be rotationally symmetrically positioned on the left and right side walls of the vehicle frame 1, the lifting mechanism can drive the supporting plate 2 to move longitudinally, and the driving mechanism can drive the wheels 3 to rotate. When the shuttle car is placed on the shelf track, the shuttle car is driven to travel by controlling the driving mechanism. When the shuttle car reaches the destination, the lifting mechanism is controlled to drive the pallet 2 to rise to lift the goods, and then the drive mechanism is controlled to make the shuttle car take When the goods exit, the movement of th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com