Hydraulic rotary system start-stop buffering device, and crane

A technology of a slewing system and a buffer device, applied in the field of hydraulic systems, can solve the problems of easy wear of brake pads, aggravate the sense of slewing drift, poor controllability, etc., and achieve the effect of facilitating heat dissipation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

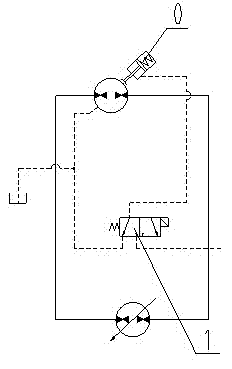

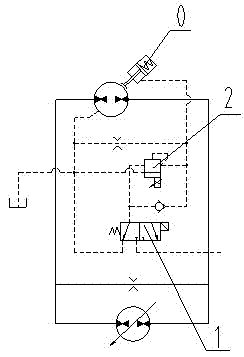

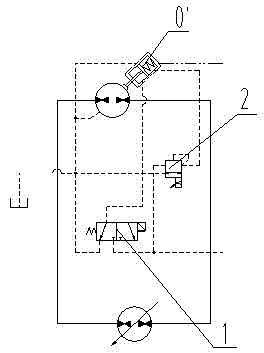

[0027] The present invention will be further described below in combination with principle diagrams and specific operation examples.

[0028] In this embodiment, a start-stop buffer device for a hydraulic rotary system is provided. The hydraulic rotary system includes a closed hydraulic pump 3 and a rotary motor 4. The oil outlet of the closed hydraulic pump 3 is connected to the oil inlet of the rotary motor 4, and the rotary The oil outlet of the motor 4 is connected to the oil inlet of the closed hydraulic pump 3, and the rotary motor 4 is connected to a brake 0. The brake cylinder of the brake 0 is normally closed, that is, the rotary motor 4 is limited by the spring force when it is not in motion. Running, only when the pressure oil enters the brake cylinder, the brake can be released by overcoming the spring force in reverse.

[0029] The buffer device 5 and the rotary motor 4 are connected in parallel on the hydraulic oil circuit. The buffer device 5 includes an oil con...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com