Novel integrated oil-water separation device

An oil-water separation device and centrifugal separation technology are applied in the direction of liquid separation, separation method, grease/oily substance/suspton removal device, etc., which can solve the problems of large energy and chemical consumption, complex equipment structure, expensive equipment, etc., to achieve Easy to operate, easy to process, and easy to popularize and apply

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

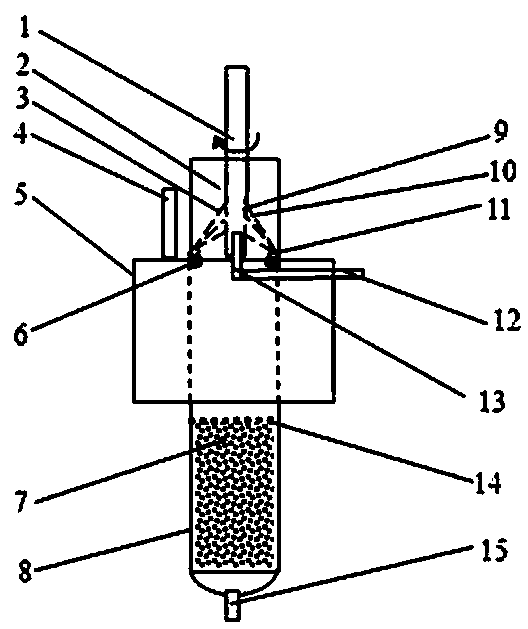

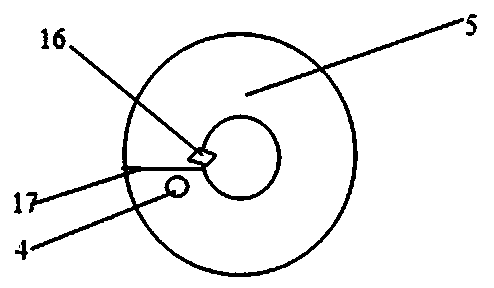

[0011] refer to figure 1 and figure 2 , the integrated oil-water separation device provided by the present invention includes two concentric inner and outer cylinders, the inner cylinder constitutes the centrifugal separation zone 2 and the adsorption separation zone 8 from top to bottom, and the inner and outer cylinders form the annulus gravity settlement Separation zone 5; Gravity sedimentation separation zone 5 has partition plate 17, the upper part of one side of the partition plate 17 has oil-water mixture inlet 4, and the other side has water outlet 16 entering centrifugal separation zone 2; Centrifugal separation zone 2 has oil-water mixture inlet 4; The pipe 13 is connected to the oil discharge port 12, and there is a discharge port 15 at the bottom of the adsorption area 8.

[0012] The centrifugal separation zone 2 is composed of a rotor part 1 and a stator part 6 with uniformly distributed balls fixed horizontally on the inner wall of the inner cylinder, wherein ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| porosity | aaaaa | aaaaa |

| porosity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com