A kind of multilayer oil-water separation material and its preparation method and application

An oil-water separation and resin layer technology, which is applied in the field of polymer materials and filter materials, can solve the problems of not being able to meet industrialized mass production and subsequent processing and application, and achieve high oil-water separation efficiency, high stability, high oil-water separation efficiency, guaranteeing applied effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

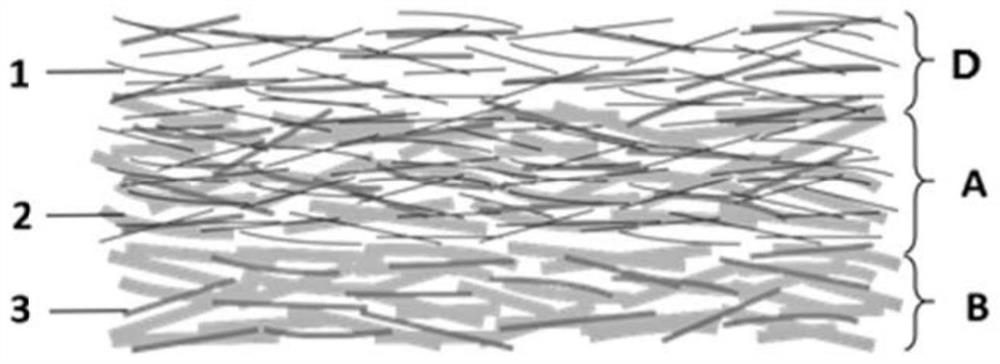

[0090] Example 1 A multi-layer oil-water separation material

[0091] The fiber composition of the multi-layer composite oil-water separation material described in this embodiment is:

[0092] (1) Kapok fiber, diameter 12.0-35.0μm, average diameter 23.0μm;

[0093] (2) Glass wool #1, diameter 0.3-9.0μm, average diameter 2.6μm;

[0094] (3) Glass wool #2, diameter 0.4-4.2μm, average diameter 1.7μm;

[0095] (4) Bicomponent PET fiber, diameter 12.5-15.2μm, average diameter 13.1μm;

[0096] Its preparation method comprises the following steps:

[0097] (1) 80 parts by mass of glass wool (glass wool #1:glass wool #2=1:3) and 20 parts by mass of bicomponent PET fibers were weighed and beaten separately for use. The two kinds of pulp were mixed and disintegrated, and the pulp was diluted to a concentration of 0.06% by mass. Then add cetyltrimethylammonium bromide with a pulp mass of 0.0024% to the slurry and stir to prepare slurry 1;

[0098] 80 parts by mass of kapok fibers...

Embodiment 2

[0101] Example 2 A multi-layer oil-water separation material

[0102] The fiber composition of the multi-layer composite oil-water separation material described in this embodiment is:

[0103] (1) Kapok fiber, diameter 12.0-35.0μm, average diameter 23.0μm;

[0104] (2) Glass wool #1, diameter 0.3-9.0μm, average diameter 2.6μm;

[0105] (3) Glass wool #2, diameter 0.4-4.2μm, average diameter 1.7μm;

[0106] (4) Bicomponent PET fiber, diameter 12.5-15.2μm, average diameter 13.1μm;

[0107] Its preparation method comprises the following steps:

[0108] (1) Weigh 20 parts by mass of kapok fibers, 60 parts by mass of glass wool (glass wool #1:glass wool #2=1:3), and 20 parts by mass of bicomponent PET fibers, respectively, and beating for later use. The kapok fiber length is 0.1-6.0mm, and the weight average length is 1.8mm. The three kinds of pulp were mixed and disintegrated, and the pulp was diluted to a concentration of 0.06% by mass. Then add cetyltrimethylammonium bro...

Embodiment 3

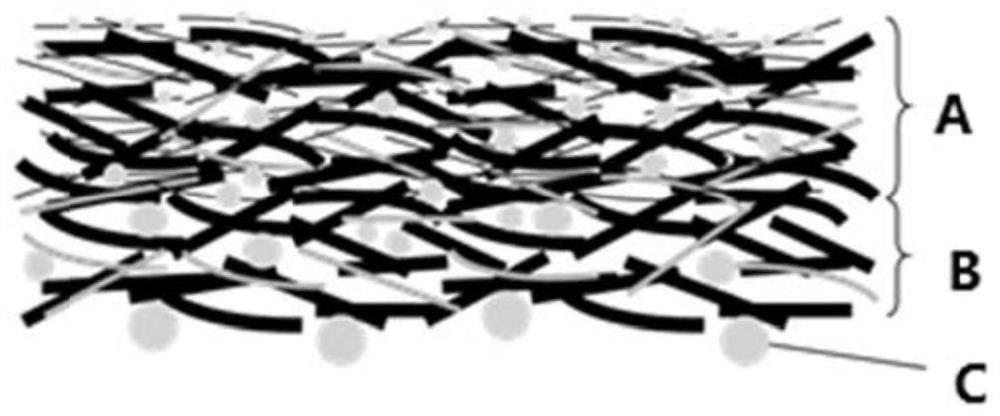

[0112] Example 3 A multi-layer oil-water separation material

[0113] The fiber composition of the multi-layer composite oil-water separation material described in this embodiment is:

[0114] (1) Glass wool #1, diameter 0.3-9.0μm, average diameter 2.6μm;

[0115] (2) Glass wool #2, diameter 0.4-4.2μm, average diameter 1.7μm;

[0116] (3) Polyester fiber (PET), diameter 21.0-25.0μm, average diameter 22.0μm;

[0117] (4) Bicomponent PET fiber, diameter 12.5-15.2μm, average diameter 13.1μm;

[0118] Its preparation method comprises the following steps:

[0119] (1) 20 parts by mass of PET fibers, 60 parts by mass of glass wool (glass wool #1:glass wool #2=1:3), and 20 parts by mass of bicomponent PET fibers were weighed, mixed and beaten, and the pulp was diluted To the mass percentage concentration of 0.06%, slurry 1 was obtained;

[0120] 80 parts by mass of PET fibers and 20 parts by mass of bicomponent PET fibers were weighed and mixed and disintegrated, and then the ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| pore size | aaaaa | aaaaa |

| pore size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com