A kind of three-dimensional printing superhydrophilic and underwater superoleophobic omentum and preparation method thereof

An underwater super-oleophobic, three-dimensional printing technology, applied in separation methods, chemical instruments and methods, membranes, etc., can solve the problems of reducing the mechanical strength of materials, destroying structures, etc., and achieve high oil-water separation efficiency, increased strength, and excellent molding The effect of the characteristic

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0026] A three-dimensionally printed superhydrophilic and underwater superoleophobic membrane and a preparation method thereof, the steps are as follows:

[0027] (1) Preparation of printing ink: 25 wt% of inorganic nano-silica particles with a particle size of 100 nm, 10 wt% of polyvinyl alcohol with a molecular weight of 10,000, 10 wt% of cellulose acetate with a molecular weight of 50,000, and the rest as tetrahydrofuran solvent , mix evenly, and remove the air bubbles in the ink by centrifugation;

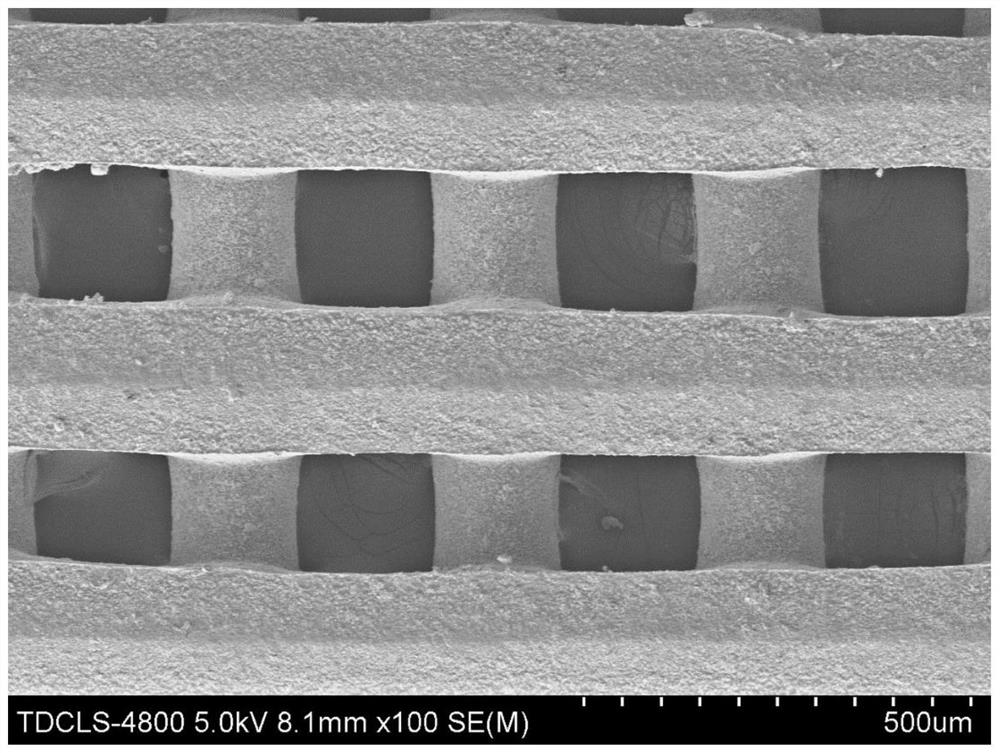

[0028] (2) Three-dimensional printing omentum process: use three-dimensional direct writing printing technology to draw the prepared printing ink on the substrate according to the periodic cross network structure to form an omentum with a grid size of 50 μm;

[0029] (3) The curing process of the omentum: put the printed omentum into a water coagulation bath for curing, the curing time is 10 minutes, the curing temperature is 50°C, and finally put it in water for storage, that ...

Embodiment 2

[0034] A three-dimensionally printed superhydrophilic and underwater superoleophobic membrane and a preparation method thereof, the steps are as follows:

[0035] (1) Preparation of printing ink: 5 wt% of inorganic nano-silver particles with a particle size of 10 nm, 30 wt% of polyvinyl alcohol with a molecular weight of 100,000, 15 wt% of cellulose acetate with a molecular weight of 10,000, and the rest as acetone solvent, Mix well and remove the air bubbles in the ink by centrifugation;

[0036](2) Three-dimensional printing omentum process: use three-dimensional direct writing printing technology to draw the prepared printing ink on the substrate according to the periodic cross network structure to form an omentum with a grid size of 500 μm;

[0037] (3) The curing process of the omentum: put the printed omentum into the ethanol coagulation bath for further curing, the curing time is 180min, the curing temperature is 10°C, and finally put it in water for storage, that is to...

Embodiment 3

[0043] A three-dimensionally printed superhydrophilic and underwater superoleophobic membrane and a preparation method thereof, the steps are as follows:

[0044] (1) Preparation of printing ink: 15 wt% of inorganic nano-alumina particles with a particle size of 55 nm, 21 wt% of polyvinyl alcohol with a molecular weight of 30000, 30 wt% of cellulose acetate with a molecular weight of 5000, and the rest of dimethyl sulfoxide-based solvent, mix evenly, and remove the air bubbles in the ink by centrifugation;

[0045] (2) Three-dimensional printing omentum process: use three-dimensional direct writing printing technology to draw the prepared printing ink on the substrate according to the periodic cross network structure to form an omentum with a grid size of 250 μm;

[0046] (3) The curing process of the omentum: put the printed omentum into the methanol coagulation bath for further curing, the curing time is 120min, the curing temperature is 30°C, and finally put it in water for...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com