Low-water-content dehydrated sludge direct supercritical water gasification processing apparatus and method

A supercritical water gasification and dewatering sludge technology, which is applied in the field of resources and environment, can solve the problems of low treatment efficiency, achieve the effect of reducing clogging and improving sludge flow performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment approach 1

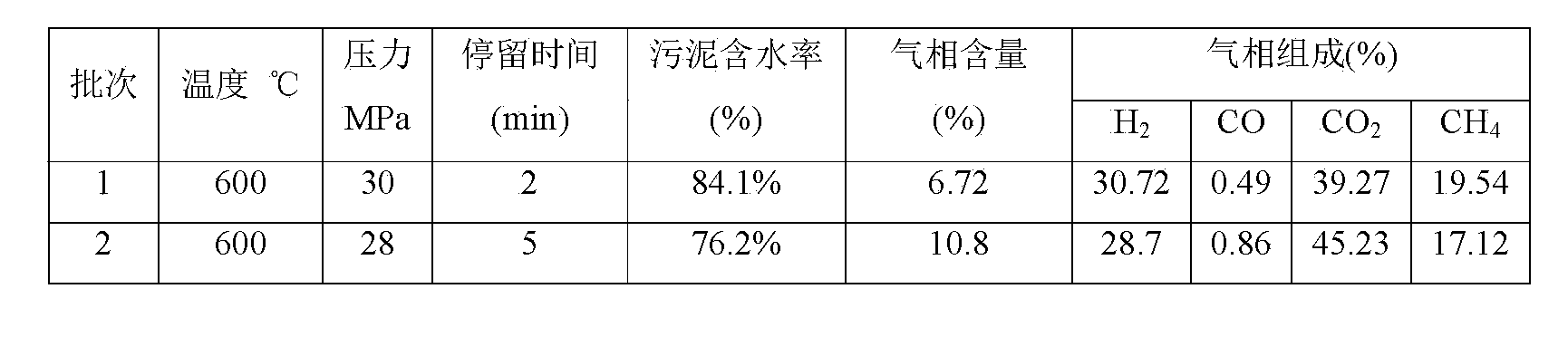

[0029] Embodiment 1 Method of direct supercritical water gasification treatment of dewatered sludge

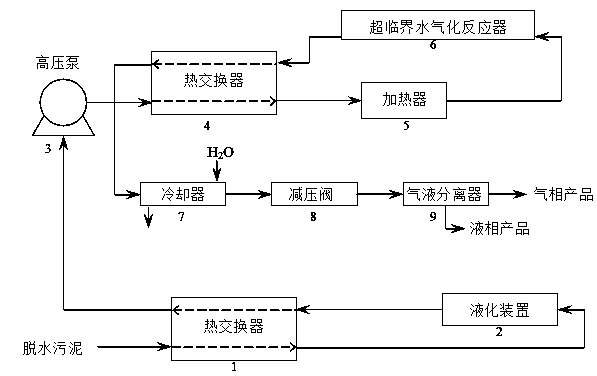

[0030] The dewatered sludge (with a water content of about 84.1%) from a sewage plant in Shenzhen is injected into the liquefaction device through a high-pressure piston pump for pre-liquefaction treatment. The liquefaction temperature is 180°C and the reaction is 30 minutes. After the liquefied product passes through heat exchanger 1, it is boosted to 25MPa with a high-pressure pump, enters the supercritical water gasification reactor and is heated to 600°C. After 2 minutes of reaction, it passes through heat exchanger 4 and cools down to about 200°C. At the same time, the heat exchanger 4 heats part of the high-pressure sludge to 500°C, and then enters the supercritical water gasification reactor. The reaction product after heat exchange by the heat exchanger 4 enters the cooler, and after cooling down to normal temperature, the pressure is reduced to normal pressure through...

Embodiment approach 2

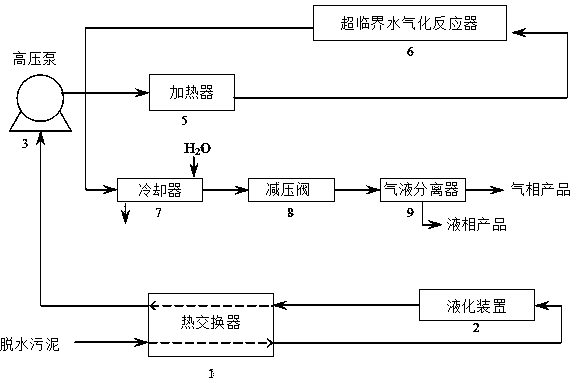

[0039] The device for direct supercritical water gasification treatment of dewatered sludge with low moisture content includes various equipment connected in series in sequence: heat exchanger 1, liquefaction device 2 high-pressure pump 3, heater 5, supercritical water gasification reaction Device 6, cooler 7, pressure reducing valve 8, gas-liquid separator 9, see figure 1 .

Embodiment approach 3

[0041] The difference from Embodiment 2 is that it also includes a heat exchanger 4, and the hot fluid passed into the heat exchanger 4 is the fluid at the outlet end of the supercritical water gasification reaction device 6, so as to recycle the supercritical water gasification reaction and flow out The heat carried by a high temperature fluid, see figure 2 .

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com