Liquid crystal reactive monomer and liquid crystal panel

An active monomer, liquid crystal panel technology, used in liquid crystal materials, nonlinear optics, instruments, etc., can solve problems such as shortening curing time and image retention, and achieve the effects of shortening curing time, improving solubility, and increasing curing speed.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

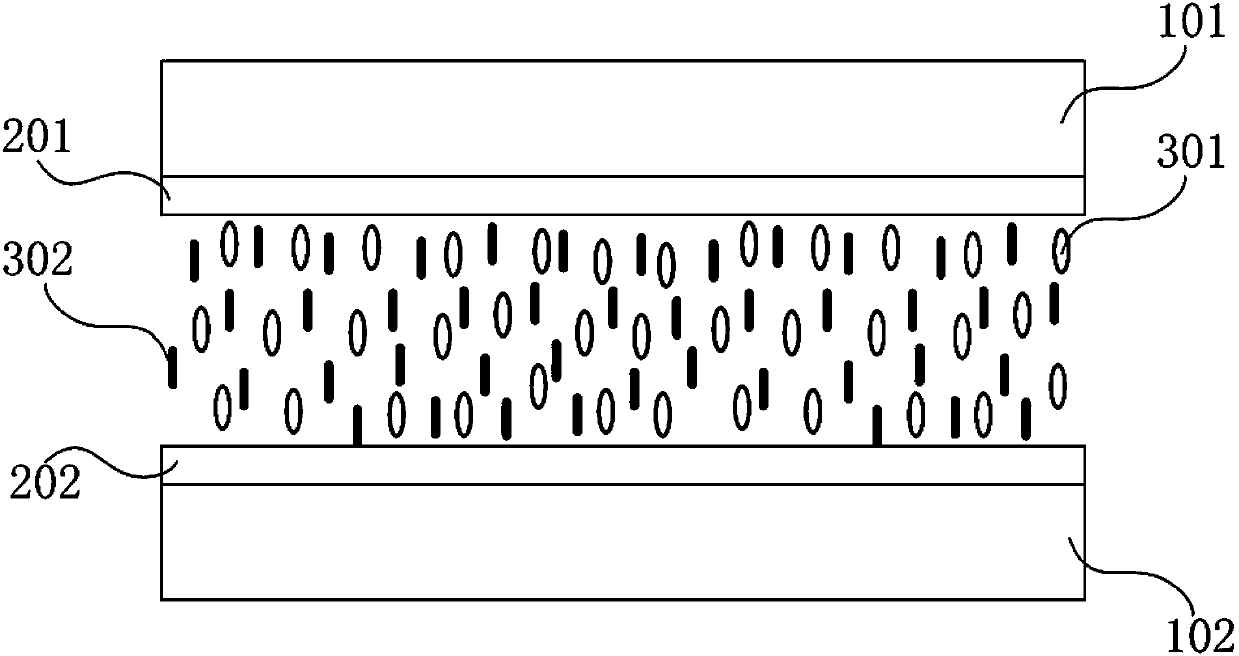

[0035] Please see attached figure 1 , with figure 1 Shown is the liquid crystal panel of the present invention, and described liquid crystal panel comprises:

[0036] A first transparent substrate 101 with a first alignment film 201; a second transparent substrate 102 with a second alignment film 202; and a liquid crystal composition filled between the first transparent substrate 101 and the second transparent substrate 102 between, and the liquid crystal composition is in contact with the first and second alignment films, wherein the liquid crystal composition includes liquid crystal molecules 301 and at least one liquid crystal active monomer 302, the general formula of the liquid crystal active monomer 302 is Ⅲ, Ⅳ or Ⅴ said.

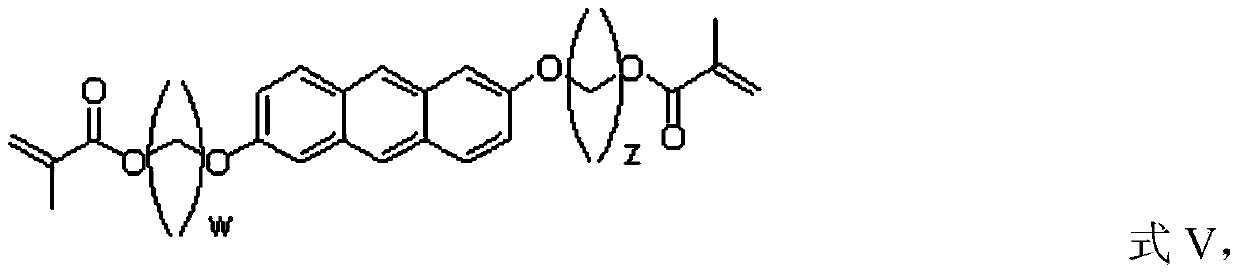

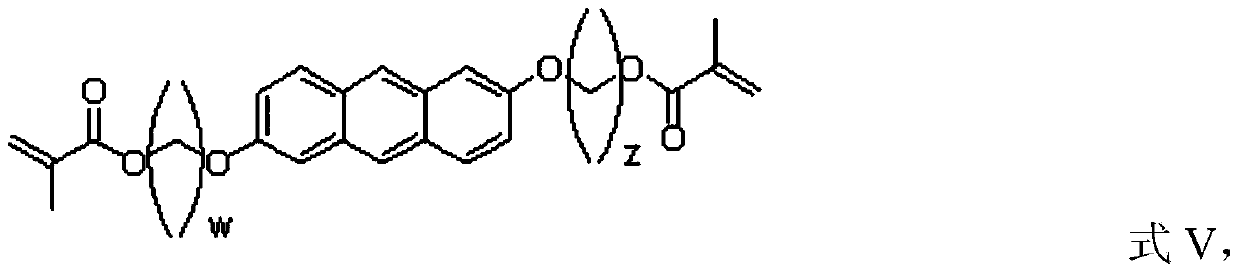

[0037]

[0038] X is selected from H or F;

[0039] p or q is the number of X groups, p or q are respectively selected from integers greater than or equal to 0 (such as 0, 1, 2...), and p+q≥1;

[0040] w or z are respectively selected from inte...

Embodiment 2

[0047] This embodiment provides a liquid crystal active monomer whose structural formula is The preparation path is:

[0048]

[0049] Concrete preparation steps are:

[0050] (A) Preparation of intermediate (1)

[0051] Dissolve 10 mmol 2,6-dihydroxyanthraquinone (2,6-Dihydroxyanthraquinone) in 150 mL of 2.0N Na 2 CO 3 solution, slowly add 127mmolNaBH 4 added to the reaction. The reaction was stirred at room temperature for 3 hours, and after gas evolution ceased, the reaction was heated to reflux for 10 minutes. After cooling, concentrated HCl was slowly added dropwise to acidify the reaction. The precipitate was collected by filtration and dissolved with acetone (acetone), and the solution was MgSO 4 Remove water and filter with air, then concentrate and vacuum to obtain a reddish-brown solid, which is finally purified by silica gel column chromatography with EA / Hexane=1 / 1, and recrystallized with ethanol to obtain light reddish-brown crystals ;

[0052] (B) ...

Embodiment 3

[0055] This embodiment provides a liquid crystal active monomer whose structural formula is The preparation path is:

[0056]

[0057] The specific steps of preparation are:

[0058] (A) Preparation of intermediate (3)

[0059] 10 mmol of intermediate (1) was dissolved in 150 mL of 2.0N KOH / THF solution, and 5 mmol of 2-bromoethanol (2-bromoethanol) was slowly added to the reaction. The reaction was heated to reflux for 24 hours. After cooling, concentrated HCl was slowly added dropwise to acidify the reaction. Extracted with EA and water, with MgSO 4 Water was removed and filtered with air, then concentrated and vacuumed to obtain a yellow liquid, which was finally purified by silica gel column chromatography with EA / Hexane=1 / 1, and recrystallized with ethanol to obtain a light yellow liquid.

[0060] (B) Preparation of target product

[0061] Put 10mmol of intermediate (3) into a 250mL double-necked bottle, use a vacuum deoxygenation and water removal device to p...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com