Burden surface temperature field detection method based on multi-source information fusion

A multi-source information fusion and detection method technology, which is applied in the field of material surface temperature field detection based on multi-source information fusion, can solve the problems of large human differences, furnace wall corrosion, and low accuracy

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0037] The present invention will be further described below in conjunction with the accompanying drawings.

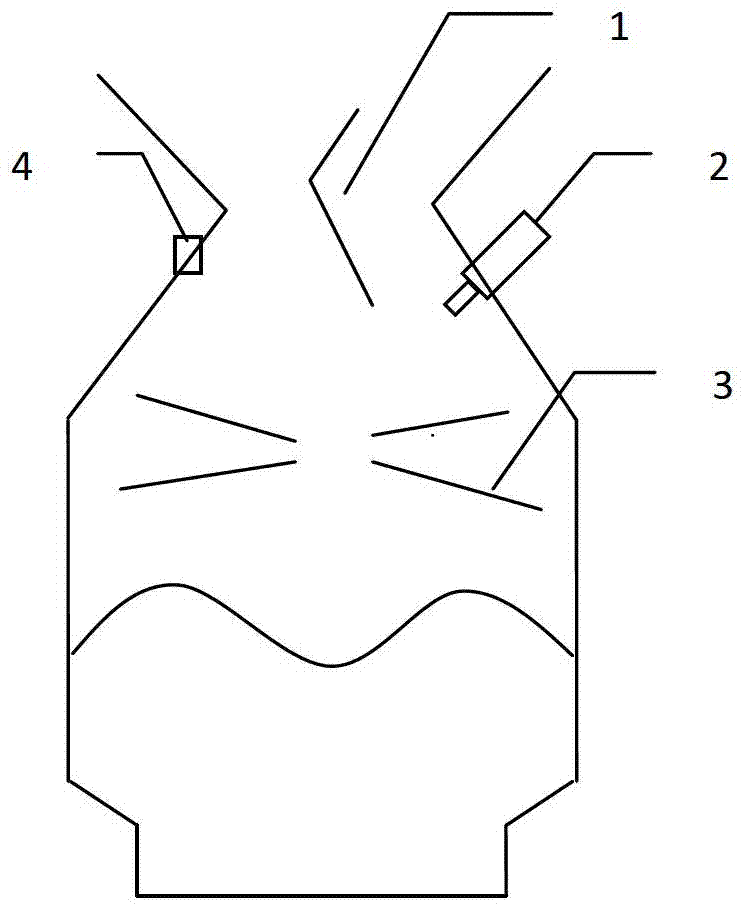

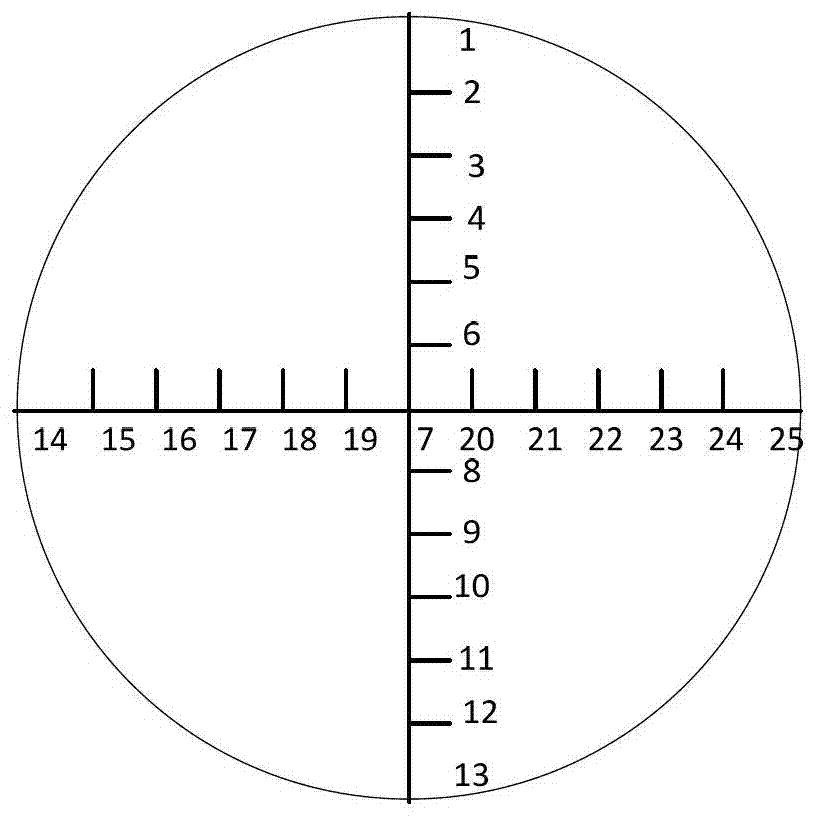

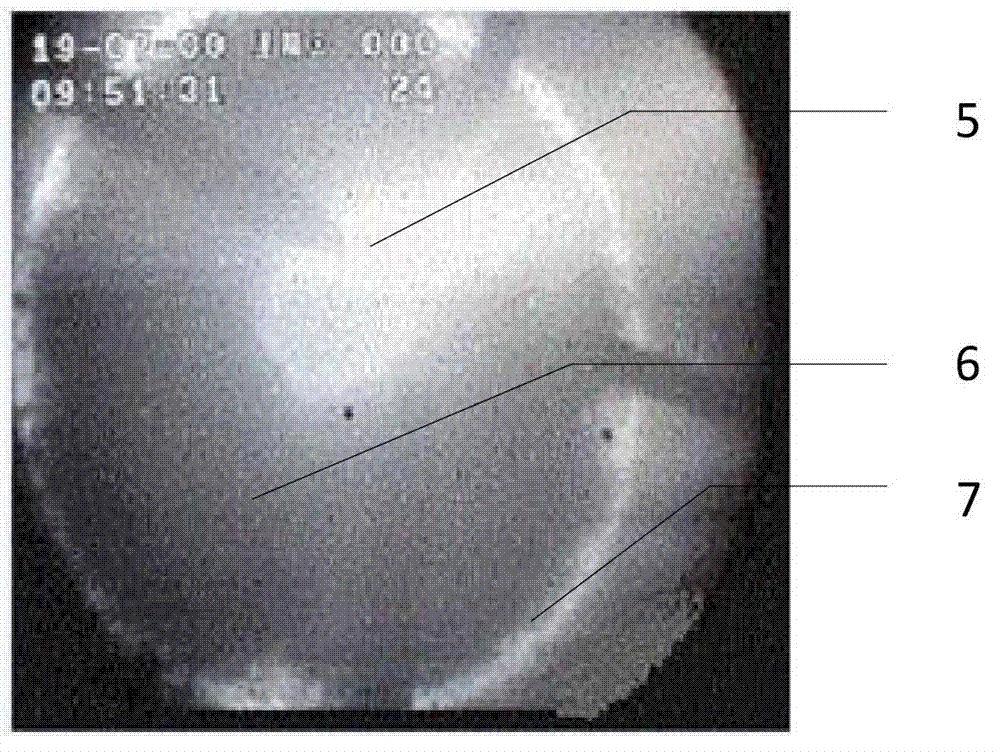

[0038] The method for establishing the temperature distribution field of the blast furnace material surface in the present invention includes the following steps: (1) data collection and time registration; (2) cross temperature measurement preprocessing and mapping modeling; (3) infrared image processing and feature extraction; (4) ) Mineral coke ratio calculation based on cloth model; (5) Support vector machine modeling based on multi-source information.

[0039] Each step is described in detail as follows:

[0040] 1. Data collection and time registration:

[0041] The present invention mainly uses the data-driven method of the support vector machine to establish the temperature field distribution model of the material surface through the detected multi-source temperature related information of the blast furnace, and first collects data, including infrared camera im...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com