Washing control method for roller washing machine and roller washing machine

The technology of a drum washing machine and its control method is applied to the control device of the washing machine, other washing machines, washing machine appliances, etc. It can solve the problems of complex control mode, inability to guarantee the pulse water curtain, and program disorder, so as to achieve good rinsing effect and benefit the health of the body Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

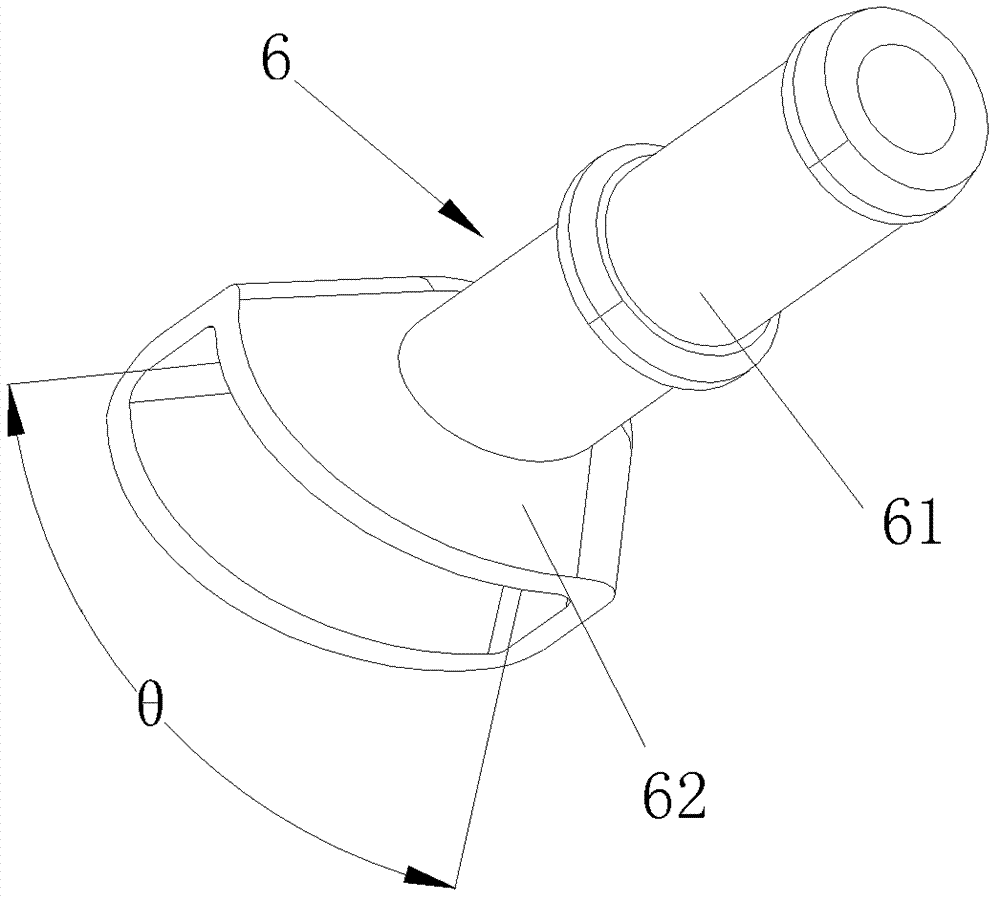

[0033] like Figure 3 to Figure 5 As shown, the nozzle 6 of the present invention includes a water inlet 61 and a nozzle 62. The nozzle 62 is a fan spray structure facing the inside of the drum. The water inlet direction of the water inlet and the fan-shaped water outlet surface of the nozzle form an acute angle α, The height difference H is 30-75°. The water outlet on the left and right sides of the nozzle has a height difference H. The height difference H is related to the front and rear depths of the drum. The included angle γ of the wall is 5-30°, preferably 10°, the included angle β between the water inlet and the nozzle is 90-120°, preferably 100°, which is beneficial to the strength of the sprayed water; the angle θ of the fan surface spray of the nozzle is 60° °-150°, preferably, θ is 75° or 90° or 105° or 120° or 150°. The nozzle structure of the present invention can not only cover the front and rear areas of the drum, so that the clothes must pass through the spray...

Embodiment 2

[0049] refer to Image 6 , in the washing process of step S1, add a high-speed drum rotation washing process, control the drum speed to 200-250r / min, in order to realize fast washing, soaking and dissolving detergent, the running time t1 can be adjusted according to the material of the clothes, the amount of clothes, and the water temperature , clothing dirtiness and other factors to adjust;

[0050] In step S5, during the circulating water spraying and rinsing process, the drum rotates at a normal rinsing speed;

[0051] In step S7, after step S6 dehydration, control the drum to maintain the rotating speed and enter the next step S8;

[0052] In step S8, during the high-speed rinsing process with clean water spraying, the drum speed is controlled to be above 250r / min, and the running time t3 can also be adjusted according to factors such as the material of the clothes, the amount of clothes, the water temperature, and the degree of dirtiness of the clothes.

Embodiment 3

[0054] The difference between this embodiment and Embodiment 2 is that in step S5, in the process of spraying and rinsing with circulating water, the drum is rinsed at a higher rinsing speed. , The drum speed and running time can also be adjusted according to factors such as the material of the clothes, the amount of clothes, the water temperature, and the degree of dirtiness of the clothes.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com