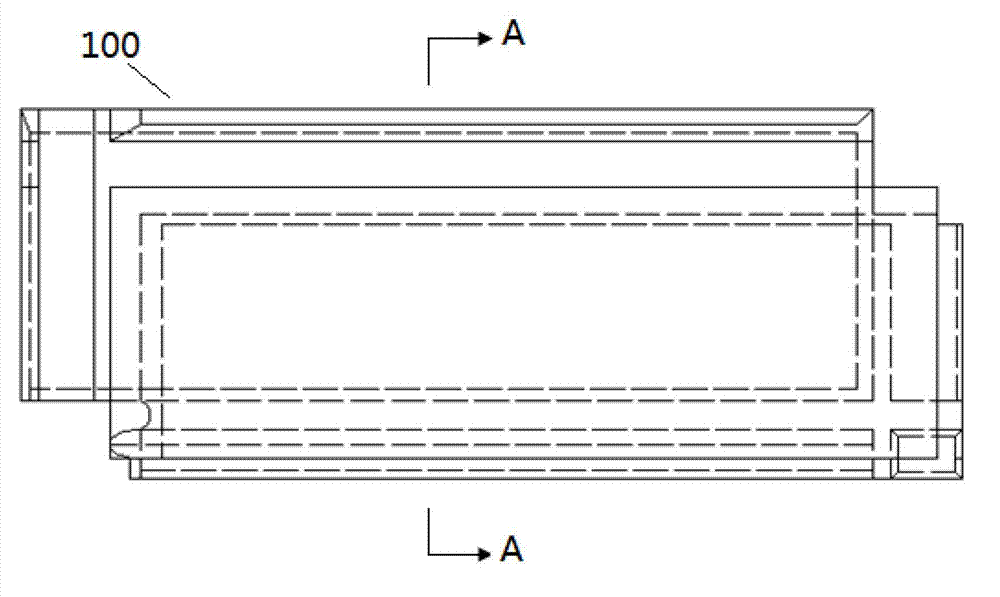

Lock buckle type split joint plastic floor tile and preparation method of lock buckle type split joint plastic floor tile

A spliced, plastic technology, applied in chemical instruments and methods, layered products, construction, etc., can solve the problems of heavy single-piece quality of locking floor tiles, inaccurate product flatness and thickness, and inconvenience, so as to reduce the need for floor tiles. The effect of good quality, dimensional stability, and ease of handling and installation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

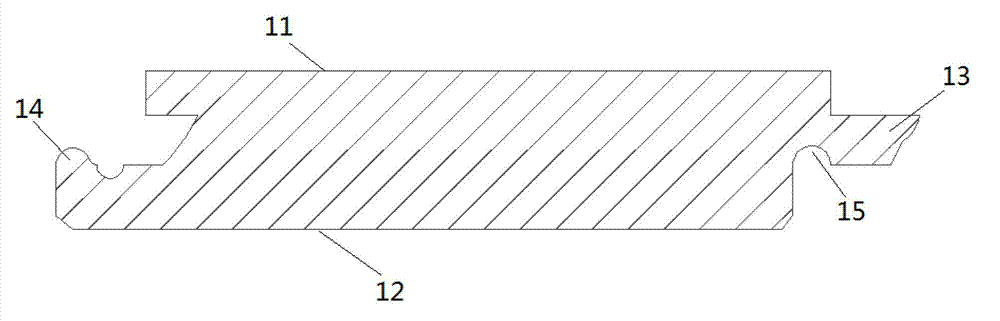

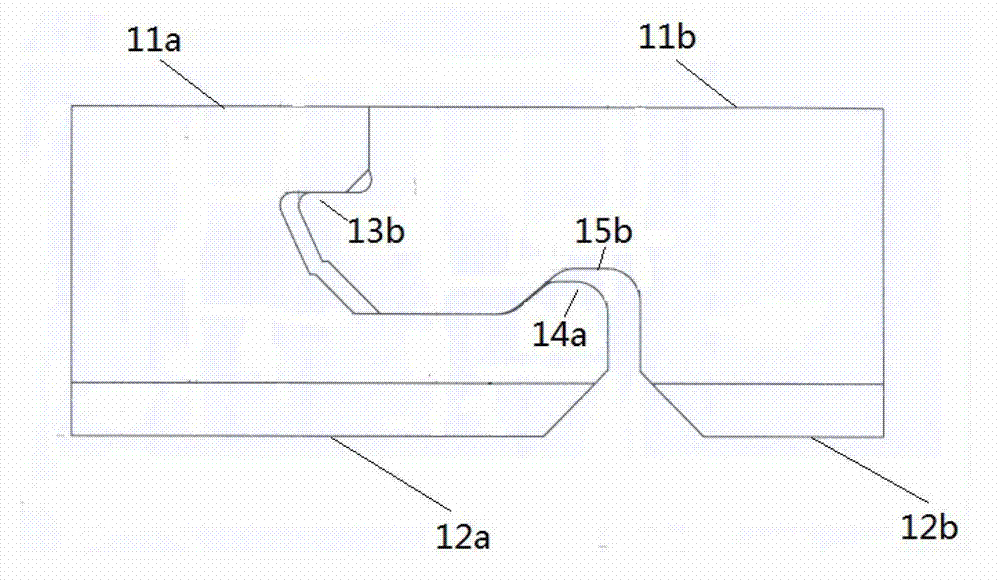

[0015] The locking type splicing plastic floor tiles involved in the present invention will be described in detail below with reference to the accompanying drawings. However, the present invention should be understood as not limited to such embodiments described below, and the technical idea of the present invention can be implemented in combination with other known technologies or other technologies having the same functions as those known technologies.

[0016] In the following description, in order to clearly show the structure and working method of the present invention, many directional words will be used to describe, but "front", "rear", "left", "right", "outer", "inner" should be used Words such as ", "outward", "inward", "upper" and "lower" are to be understood as convenient terms, and should not be understood as restrictive terms. In addition, the word "below" used in the following description mainly refers to the side close to the ground, the word "upper" mainly re...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| density | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com