Anti-corrosion dust collection energy-saving chimney

A chimney and flue technology, applied in the field of anti-corrosion dust collection and energy-saving chimneys, can solve the problems of high cost, poor flow disturbance effect, corrosion of the cylinder body, etc., and achieve the effects of prolonged service life, good flow diversion effect, and low self-resistance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 2

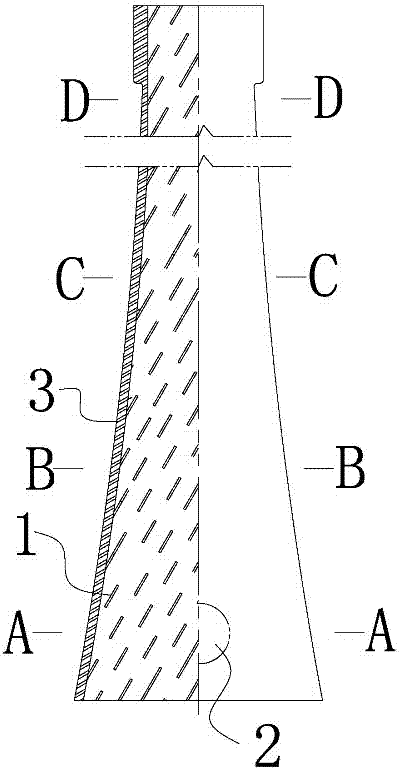

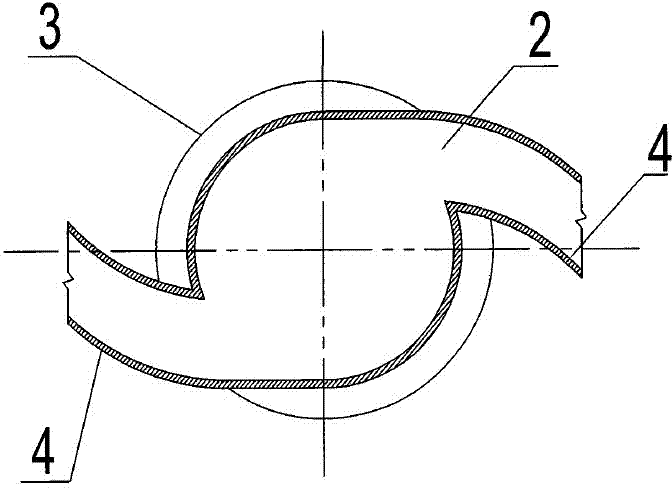

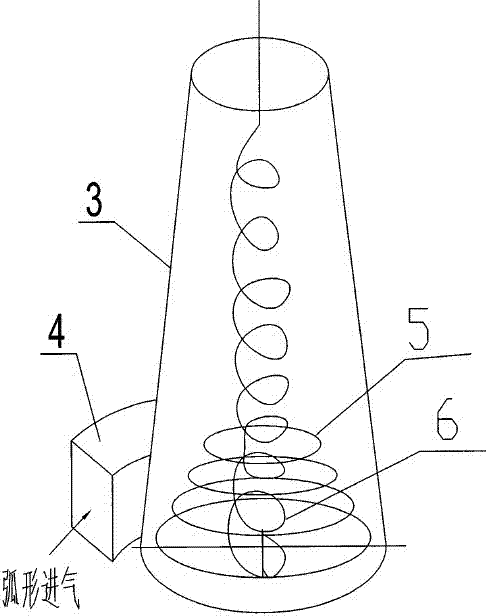

[0034] A kind of anti-corrosion and dust collection energy-saving chimney, such as Figure 7 As shown, it comprises a chimney body 3 made of equal diameter steel with a height of 120 m. The diameters of the chimney body 3 with different horizontal sections of the chimney body 3 are equal, and the spoiler rib 1 at a position with a high level is formed by the chimney body 3 The height H that the inner wall protrudes toward the center of the chimney cylinder 3 h = the height H that the spoiler rib 1 protrudes from the inner wall of the chimney cylinder 3 to the center of the chimney cylinder 3 at a position with a low horizontal height L . The rest of the structural features are the same as those in Embodiment 1 and will not be repeated here.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com