Axial supporting device

A support device, axial technology, applied in the direction of bearings, ball bearings, bearing components, etc., can solve the problem of high tool cost, and achieve the effect of saving tool cost, reliable function, and avoiding self-locking

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

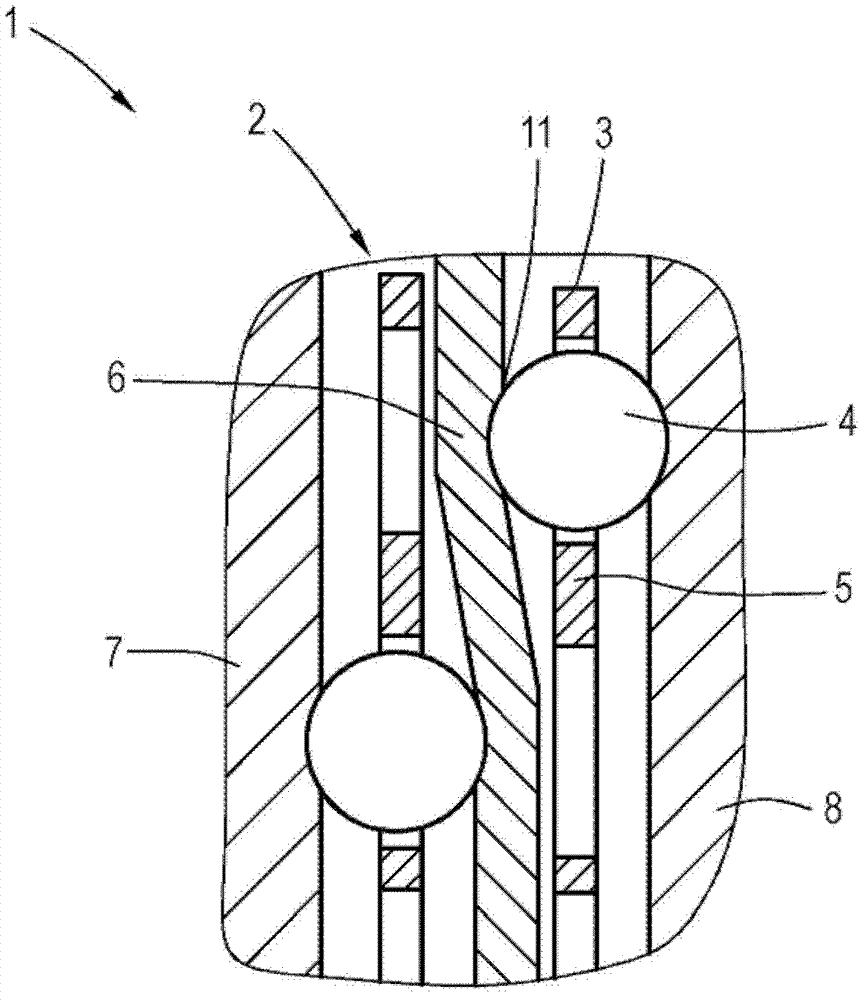

[0017] exist figure 1 The axial bearing 1 shown in the sectional side view of FIG. 2 comprises two rolling bearings 2 , 3 each having a rolling body 4 configured as a ball, which is accommodated in a cage 5 . The cage 5 is made of plastic material.

[0018] Roller bearings 2 , 3 are arranged parallel to one another with a component between them, which in the exemplary embodiment shown is designed as toothed segment 6 . The toothed segment 6 is a component part of an actuator for an electric axle of a vehicle. This electric axle includes a transmission, which is switched between two transmission stages by actuating an actuator. The toothed segment 6 is thus displaced axially during the shifting process.

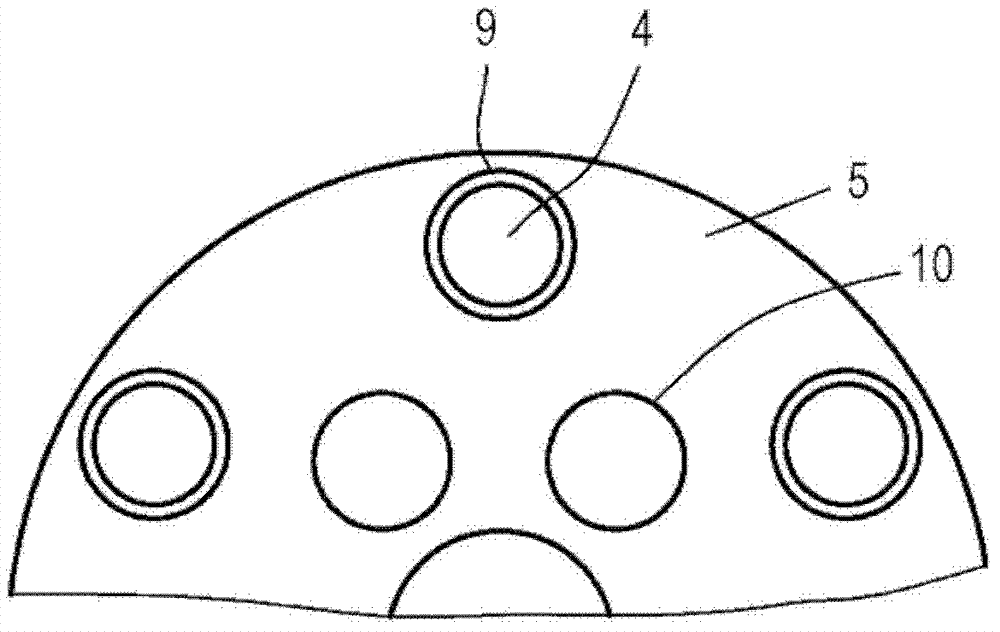

[0019] The rolling bodies 4 of the two rolling bearings 2 , 3 are each supported on the outer sides on raceways 7 , 8 . as best in the figure 2 As can be seen in the side view of , the cage 5 has a first opening 9 for a first (outer) pitch circle and a second opening 10 ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com