Sea platform uplift reducer bearing clearance adjusting method and special tool therefor

A bearing clearance and offshore platform technology, applied in metal processing, manufacturing tools, transmission parts, etc., can solve problems such as poor stability of axial clearance precision control, influence of reducer service life, and difficult control of axial clearance, and achieve high precision Good stability, extended service life and high precision

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0021] The specific method steps are:

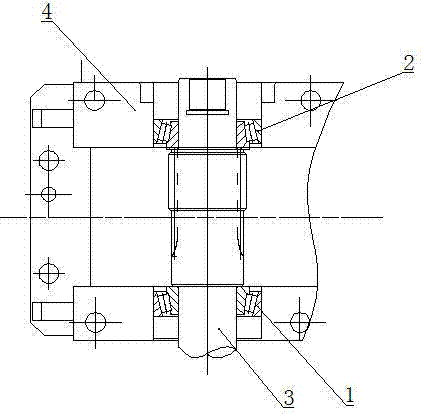

[0022] a) if figure 1 As shown, first, the two ends of the reducer shaft 3 are connected to the bearing A1 and the bearing B2, and the bearing A1 and the bearing B2 are installed in the bearing installation holes on the two side walls of the reducer housing 4 . The bearing A1 at one end is limited by the step surface of the bearing installation hole of the reducer housing 4 or other structures, and the bearing B2 at the other end is not limited.

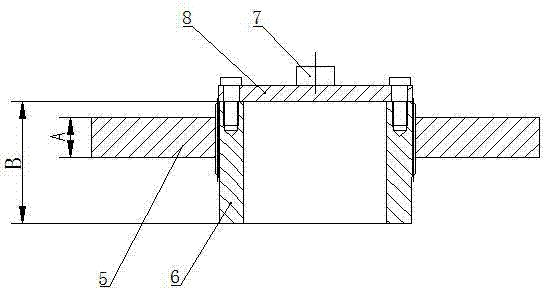

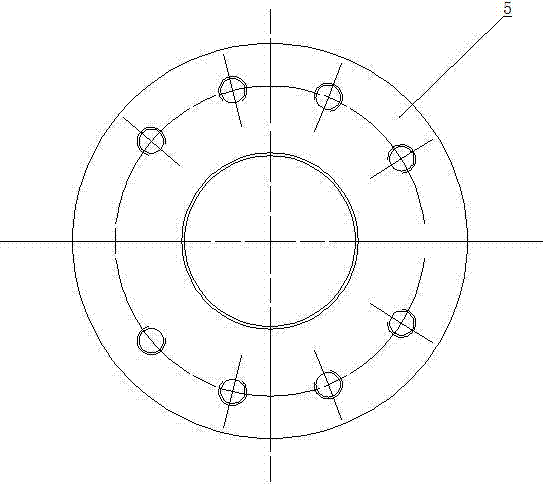

[0023] b) Then install the clearance adjustment gland 5 of the special tooling outside the bearing installation hole of the bearing B2, and the clearance adjustment gland 5 and the outer wall of the reducer housing 4 on this side are fixed by bolts.

[0024] In this step, a special tool for realizing the method of adjusting the bearing clearance of the lifting reducer of the offshore platform is involved, such as figure 2 , 3 As shown, it includes: a flange-shaped gap adjustment gland 5, a ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com