Light-emitting diode (LED) illumination module

A technology of LED lighting and LED light source, which is applied in the field of optics, can solve the problems of not meeting the requirements of light distribution and single light distribution effect, and achieve the effect of improving utilization rate and uniform light spot

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

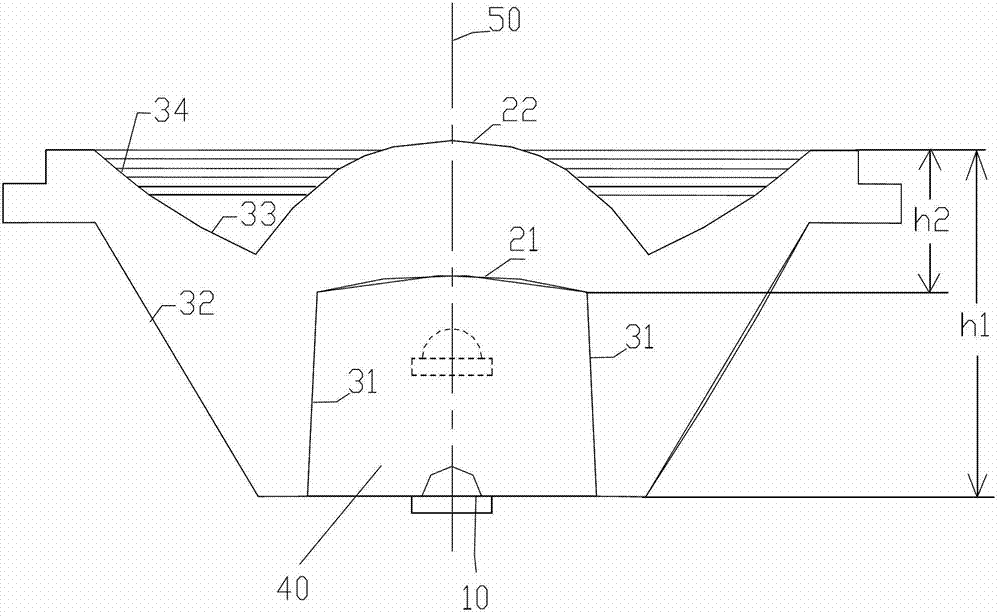

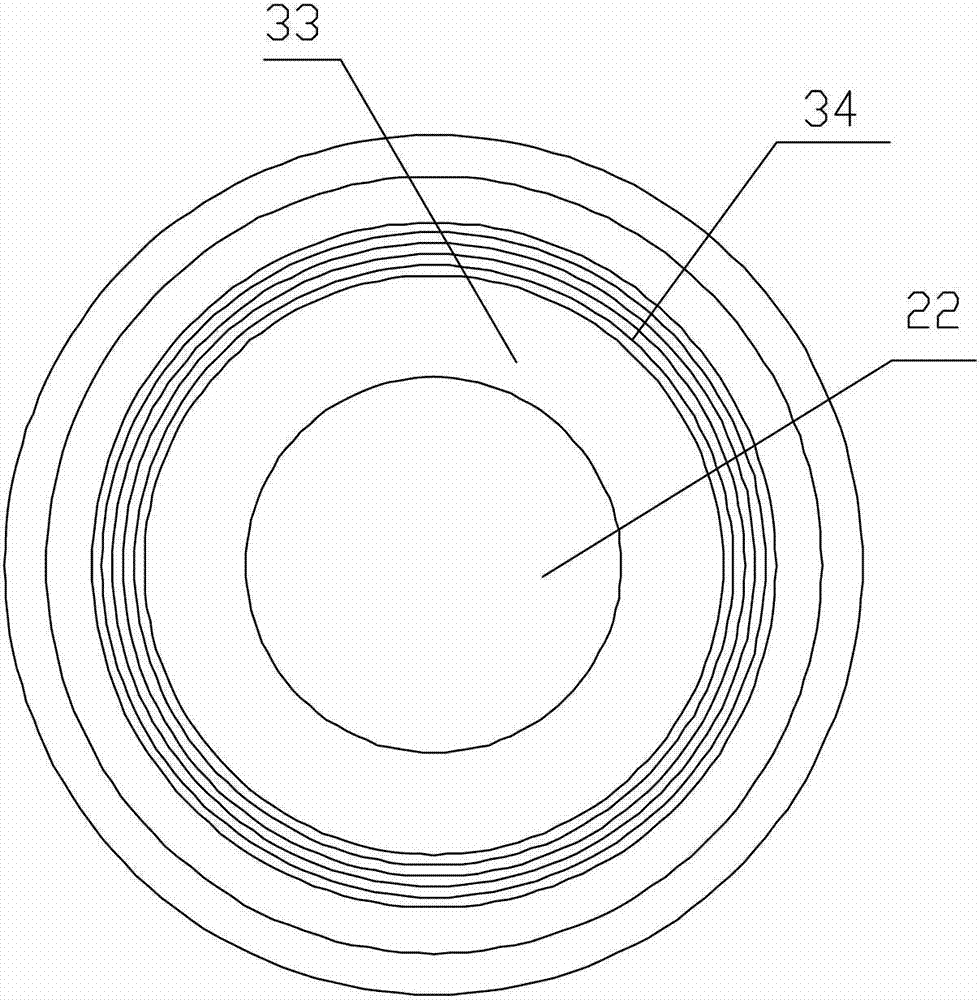

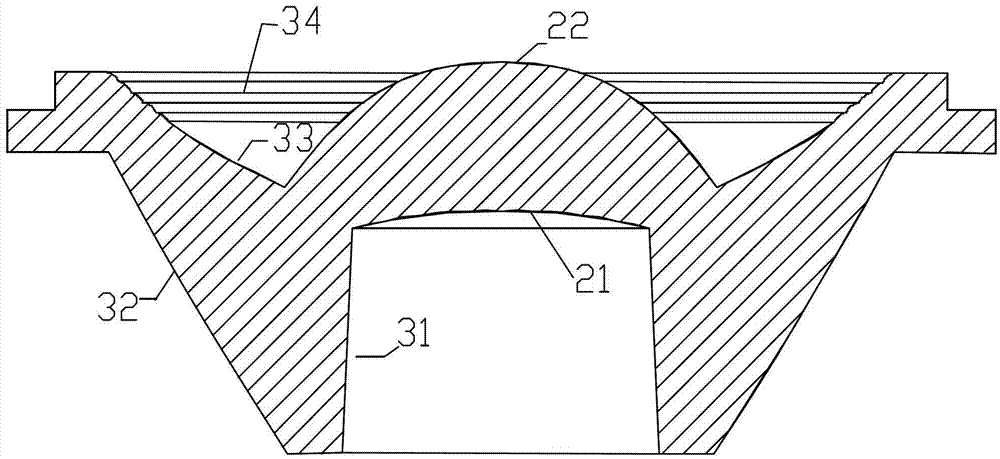

[0028] The LED lighting module structure of the preferred embodiment of the present invention is as follows: figure 1 , figure 2 , image 3 shown, see also Figure 4 and Figure 5 , the LED lighting module includes an LED light source 10 and a rotationally symmetrical single-piece light-transmitting auxiliary optical structure. The light-transmitting auxiliary optical structure is a secondary optical system, including a flood lens group 20 located in the middle, a reflective lens group 30 located around, and a blind hole-shaped opening 40 located on the back, where the LED light source 10 is disposed. Wherein, the opening 40 includes a concave curved base surface 21 and a tapered circumferential surface 31, and the opening 40 has a circumferential diameter that allows the LED light source 10 to move relatively along the optical axis 50 of the light-transmitting auxiliary optical structure; the flood lens group 20 includes as The base surface 21 of the light incident surfa...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com