LED (Light Emitting Diode) strip-shaped lamp and manufacturing method thereof

An LED strip light and the technology of the manufacturing method are applied to the cooling/heating device of the lighting device, the lighting and heating equipment, the semiconductor device of the light-emitting element, etc., and can solve the problem of low luminous flux rate of the plastic lamp tube, unsatisfactory heat dissipation effect, Reduce the utilization rate of light sources and other issues, and achieve the effect of good heat dissipation, simple structure, safe and reliable use

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

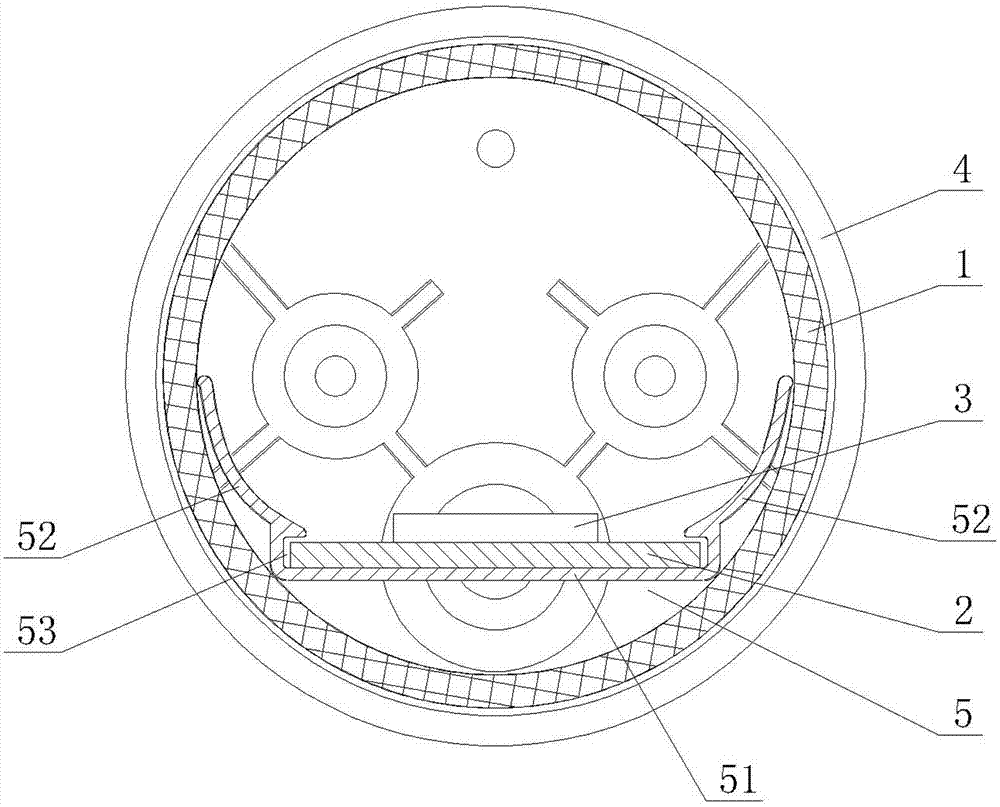

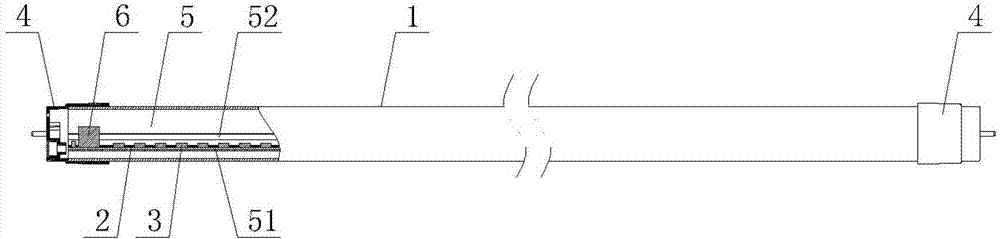

[0023] Such as Figure 1-Figure 4 As shown, the LED strip lamp according to the present invention includes a strip lamp tube 1, an aluminum substrate 2 and an LED lamp bead 3, wherein the LED lamp bead 3 is patched on the aluminum substrate 2, and the LED lamp bead 3 is pasted The aluminum substrate 2 is installed in the strip-shaped lamp tube 1, and the strip-shaped lamp tube 1 is a glass lamp tube. In order to make the LED strip light of the present invention have various lighting effects on the basis of high light efficiency, the above-mentioned glass lamp tube is a transparent glass lamp tube or a frosted glass lamp tube. In order to improve the versatility and convenience of the LED strip light of the present invention, a lamp cap connector 4 is provided at both ends of the strip light tube 1 . In order to further increase the service life of the LED strip light of the present invention and effectively improve its heat dissipation efficiency, a heat dissipation base 5 is...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com