Method for measuring relationship between external load of ceramic soldering joint and metal deformation of welding line

A technology of weld metal and brazing joint, which is applied in the field of measuring the relationship between the external load of the welded joint and the deformation of the weld metal

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment approach 1

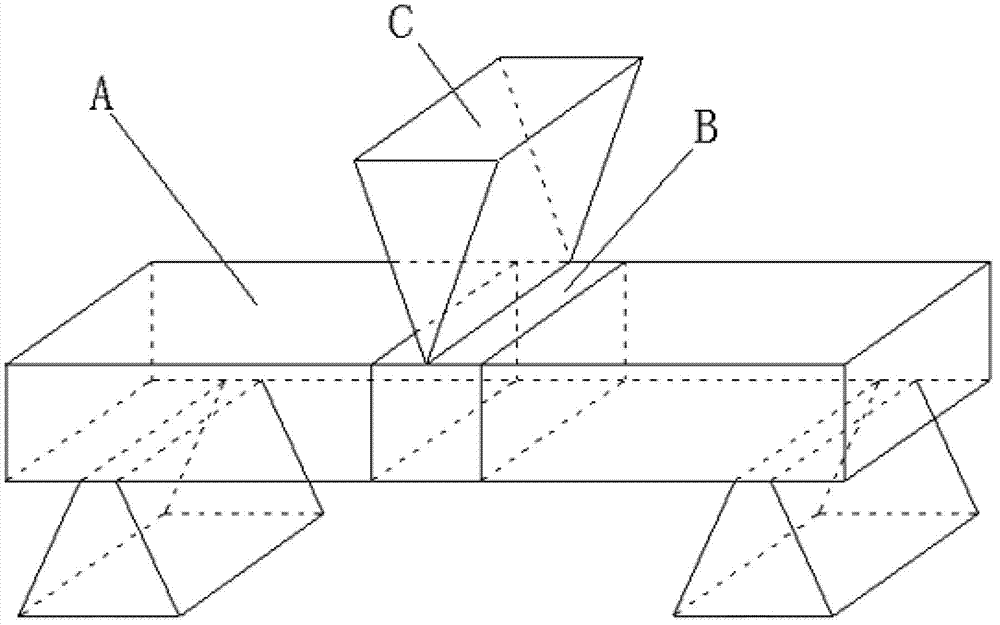

[0009] Specific implementation mode 1: This implementation mode is a method for measuring the relationship between the external load of a ceramic brazing joint and the deformation of the weld metal, which is specifically completed according to the following steps:

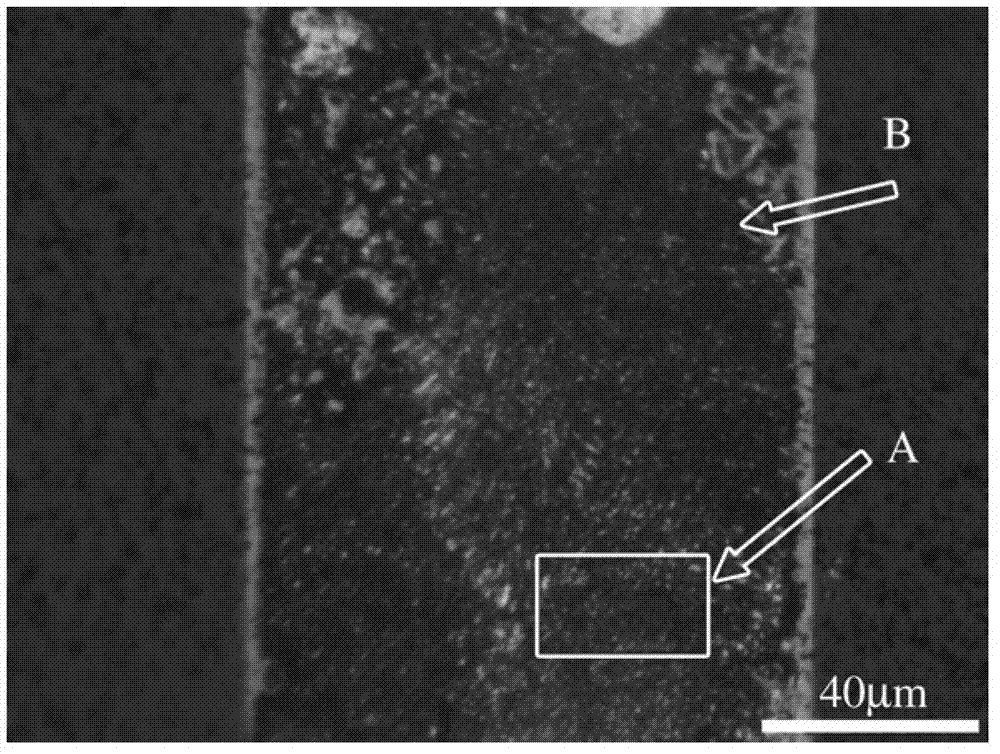

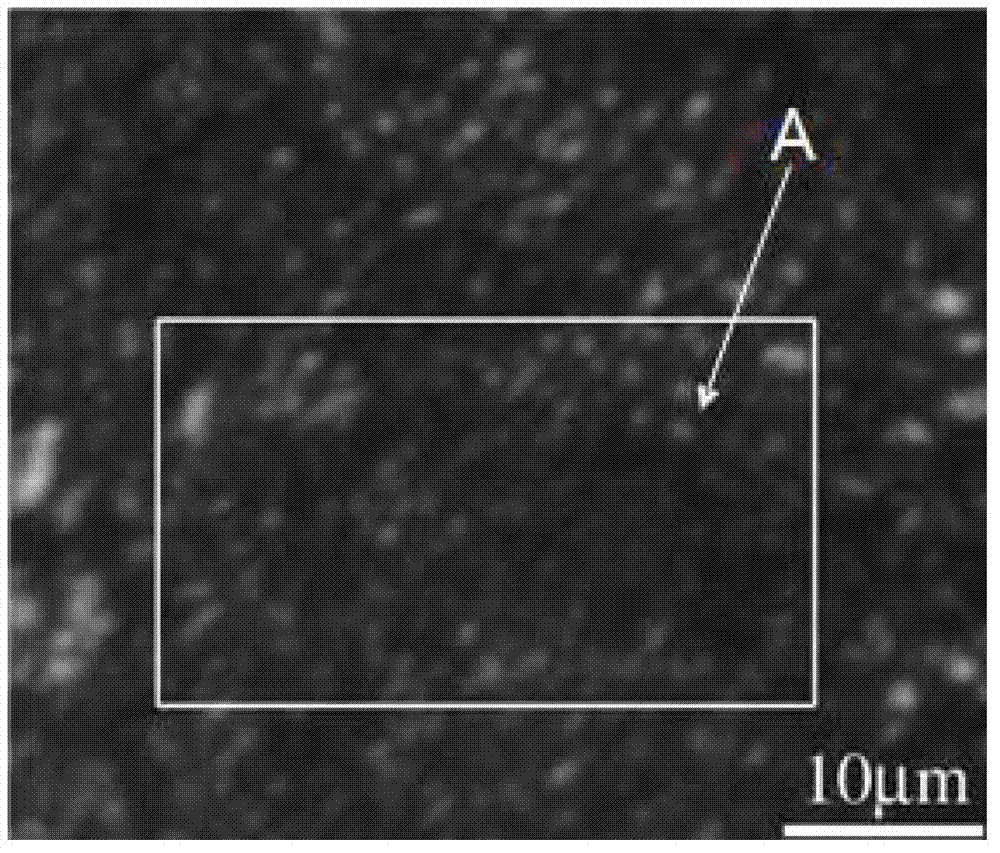

[0010] First, select the welding plate obtained by ceramic brazing as the test piece, and then conduct a three-point bending test on the test piece. The loading position of the external load is required to be directly above the center of the weld seam of the test piece, and a metallographic microscope is used in the process of carrying the external load. Record the deformation pictures of the weld under different load conditions, and then use the digital image fitting method to analyze the deformation pictures with DIC software to obtain the deformation of the weld metal under different load conditions. The relationship between the amount of deformation of the weld metal of the test piece.

[0011] This embodiment ...

specific Embodiment approach 2

[0012] Embodiment 2: The difference between this embodiment and Embodiment 1 is that a stepper motor is used to load the load, which is as follows: a stepper motor is used to drive the left-right ball screw to rotate, and the two nuts on the screw Make the two fixtures move in the same direction at the same speed at the same time, and then realize the in-situ bending of the weld seam of the piece to be tested. Others are the same as the first embodiment.

specific Embodiment approach 3

[0013] Embodiment 3: The difference between this embodiment and Embodiment 1 or 2 is that the method of segmented loading is adopted, specifically as follows: after a single loading is completed, first use a metallographic microscope to record and detect the weld seam of the welding plate. After the photo, proceed to the next load. Others are the same as those in Embodiment 1 or 2.

[0014] Adopt following test to verify effect of the present invention:

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com