Constant-pressure water jet cavitation test device

A cavitation test, water jet technology, applied in the direction of testing wear resistance, etc., can solve the problems of poor versatility, complex structure, and inaccurate characterization of the device, and achieve easy anti-cavitation performance, compact and reasonable structure, and flexible disassembly easy effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0016] The present invention will be further described below in conjunction with the drawings and specific embodiments.

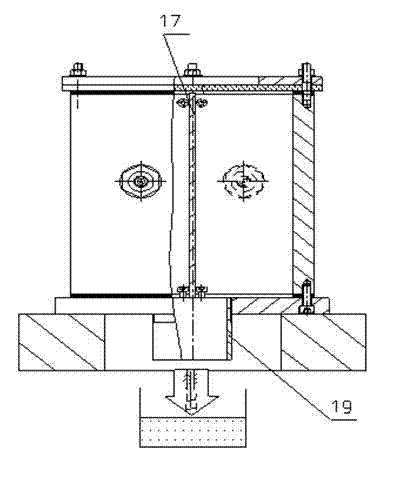

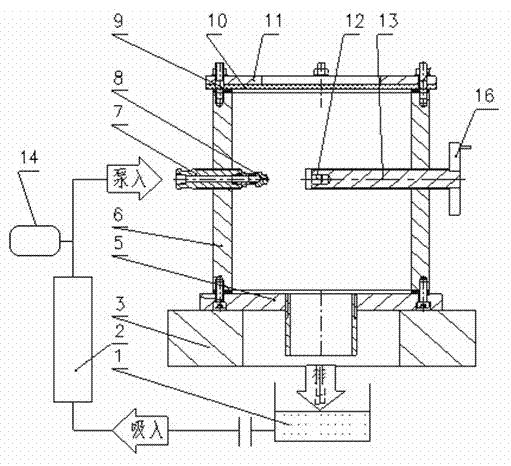

[0017] Such as figure 1 with 2 Shown: a constant pressure water jet cavitation test device, the constant pressure variable frequency water supply equipment 2 is a water supply equipment 2DRL2-22 with two vertical pumps, connected to the diaphragm pressure tank 14, and connected to two jet nozzles 8 in two ways , There is a partition 17 between, the jet nozzle 8 adopts 2012GG series SiC ceramic material jet solid cone nozzle, the nozzle diameter is 0.8-2mm, the nozzle adopts G1 / 8 sealing pipe thread, and is installed on the left and right nozzle fixed pipes The nozzle fixing tube 7 and the sample fixing tube 13 are both installed on the wall of the jet chamber 6 with fine thread pairs. The sample fixing tube 13 is equipped with a handwheel 16 and the jet chamber 6 is made of aluminum with a specification of 232X17. Tube profile, the upper end surface is equipp...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com