Multi-channel Parallel Laser Ultrasonic Testing System

A detection system, laser ultrasonic technology, applied in measuring devices, material analysis through optical means, instruments, etc., can solve problems such as limited detection speed, achieve high detection efficiency, fast scanning speed, and improved laser ultrasonic detection speed Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

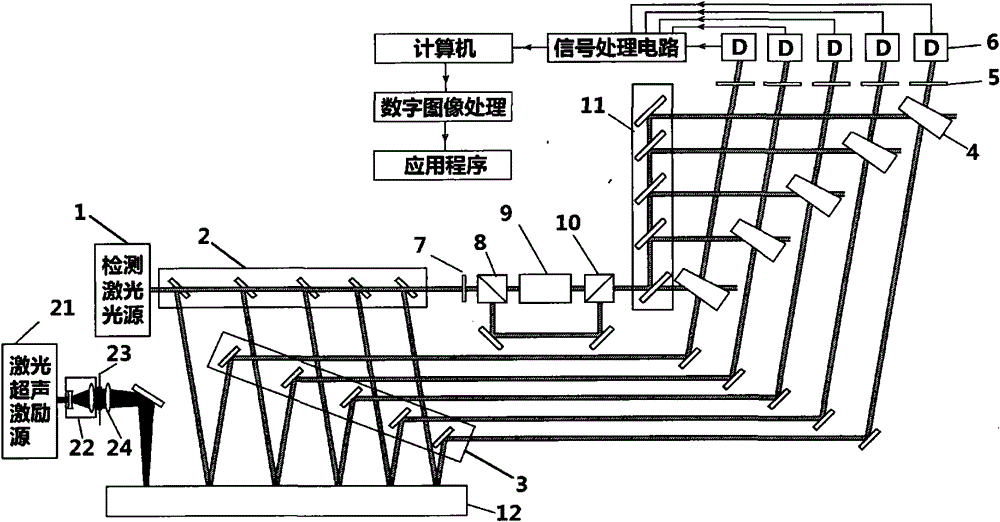

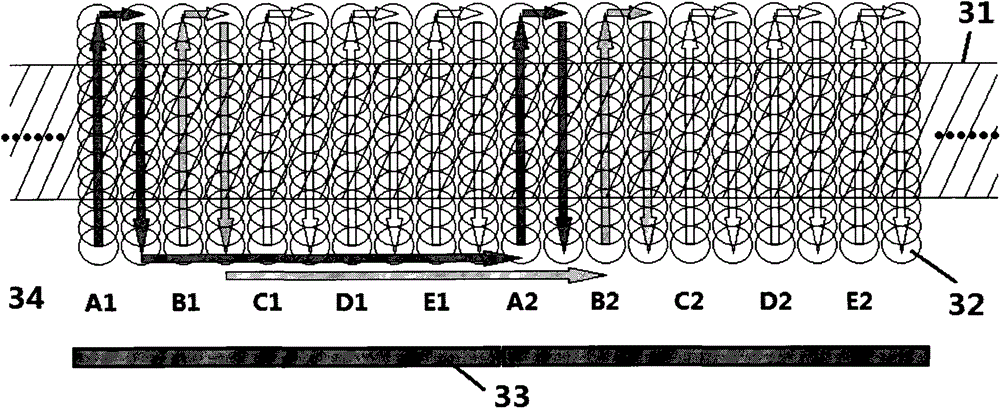

[0031] According to the instructions, a set of multi-channel parallel laser ultrasonic detection system of the present invention is produced, including a detection laser light source 1, a front beam splitting structure 2, an acquisition structure 3, a birefringent crystal 4, a polarizer 5, a detector 6, a dichotomous One wave plate 7, front polarizing beam splitting prism 8, acousto-optic modulator 9, rear polarizing beam splitting prism 10, rear beam splitting structure 11, detected object 12, laser ultrasonic excitation source 21, beam expander structure 22, bidirectional adjustable diaphragm 23, focusing mirror 24. Such as figure 1 shown. Wherein, the front splitting structure 2 can divide the signal light into 5 beams, and the collection structure 3 collects the 5 beams of signal light respectively. The front beam splitting structure 2 is a mirror group composed of 5 mirrors, the detector 6 is a scientific CCD, and the acquisition structure 3 is a mirror group composed o...

Embodiment 2

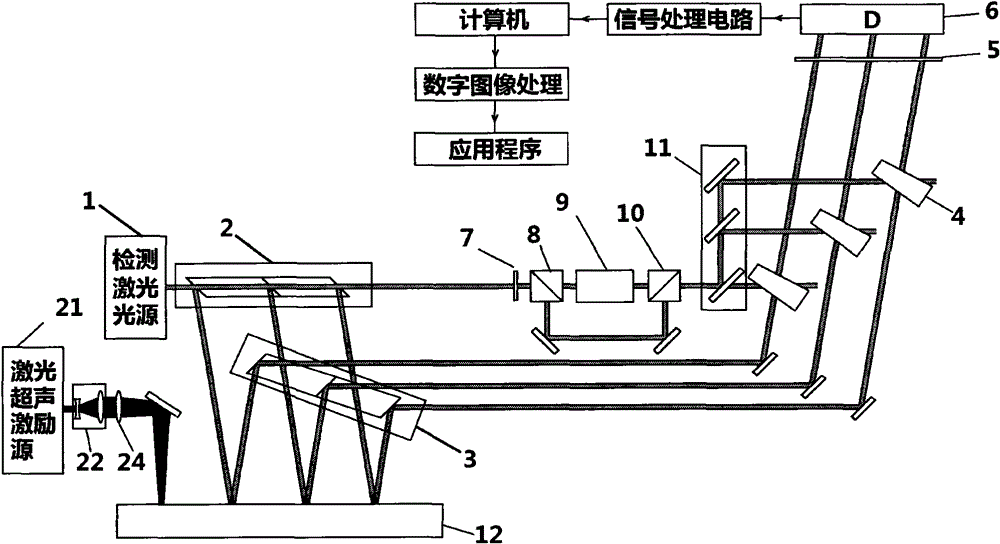

[0035] According to the instructions, a set of multi-channel parallel laser ultrasonic detection system of the present invention is produced, including a detection laser light source 1, a front beam splitting structure 2, an acquisition structure 3, a birefringent crystal 4, a polarizer 5, a detector 6, a dichotomous A wave plate 7, a front polarizing beam splitting prism 8, an acousto-optic modulator 9, a rear polarizing beam splitting prism 10, a rear beam splitting structure 11, a detected object 12, a laser ultrasonic excitation source 21, a beam expander structure 22, and a focusing mirror 24. Such as image 3shown. Wherein, the front splitting structure 2 can divide the signal light into 3 beams, and the collection structure 3 collects the 3 beams of signal light respectively. The front light splitting structure 2 is an optical structure composed of two prisms, the detector 6 is a CMOS image acquisition device, and the acquisition structure 3 is an optical structure com...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com