Light emitting diode (LED) lamp panel packaging structure and method thereof

A technology of LED light board and packaging structure, applied in the direction of semiconductor devices, electrical components, circuits, etc., can solve the problems of affecting life, large chip current, current difference, etc., to achieve the effect of improving efficiency and ensuring design life

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0023] Reference herein to "one embodiment" or "an embodiment" refers to a particular feature, structure or characteristic that can be included in at least one implementation of the present invention. "In one embodiment" appearing in different places in this specification does not all refer to the same embodiment, nor is it a separate or selective embodiment that is mutually exclusive with other embodiments.

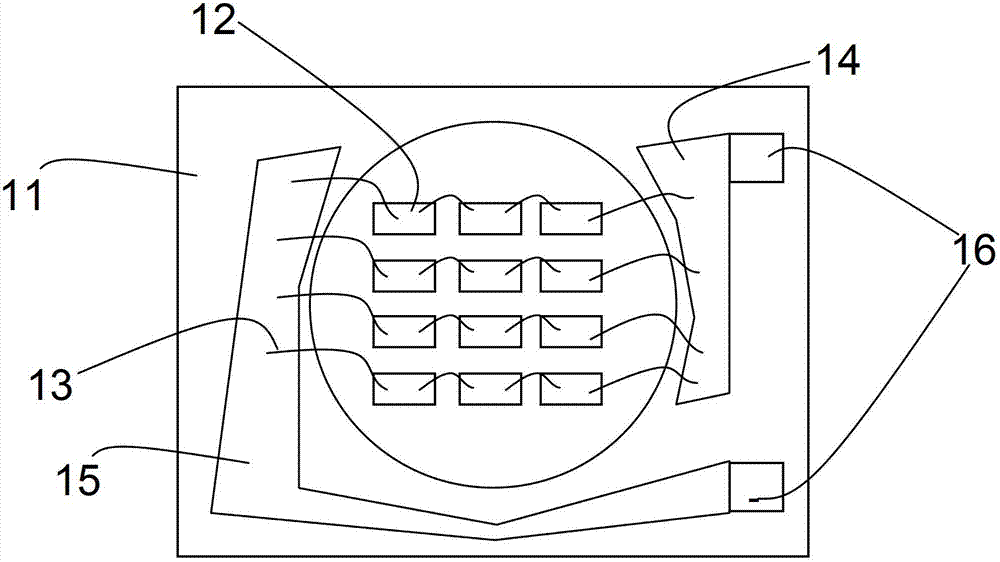

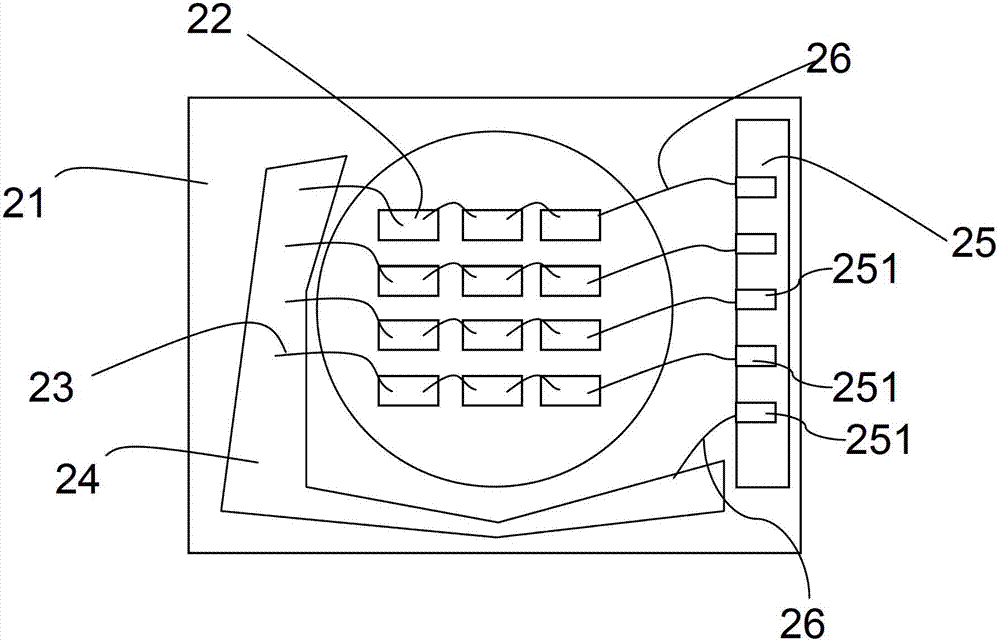

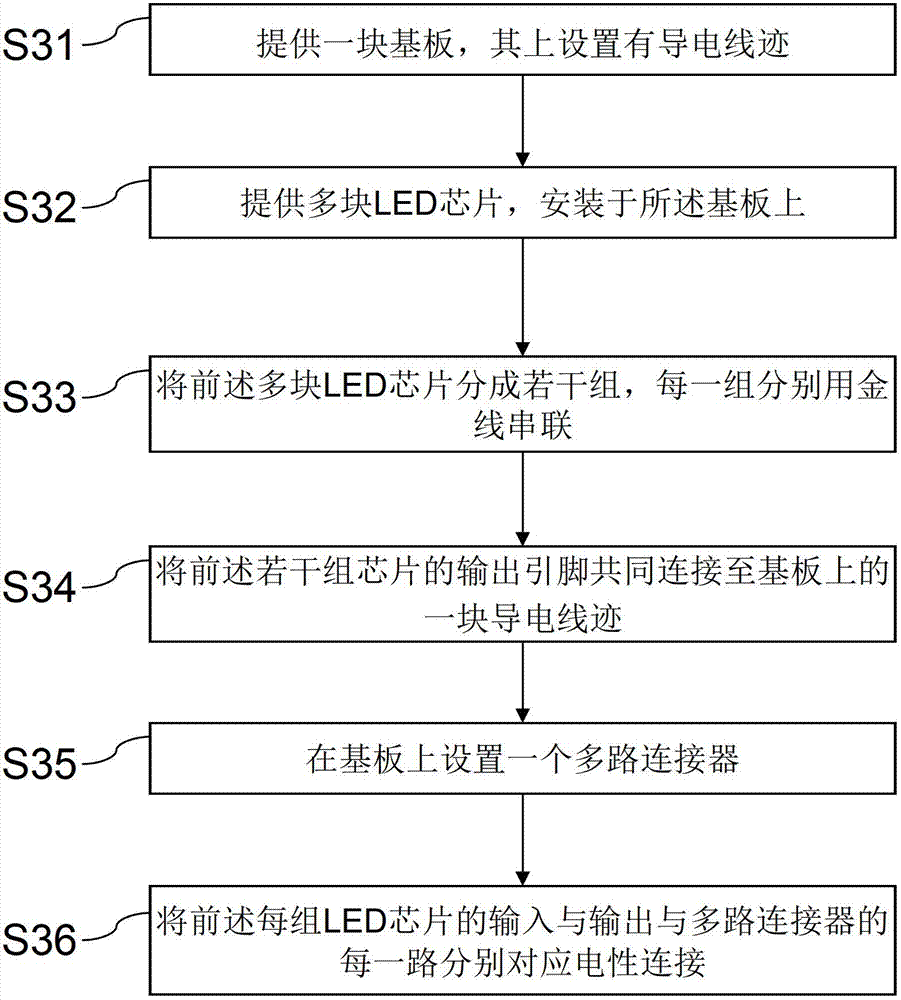

[0024] see figure 2 As shown, it shows a schematic diagram of the packaging structure of the LED light board of the present invention. Such as figure 2 As shown in , the package structure of the LED light board of the present invention includes a package substrate 21 , wherein the package substrate 21 is provided with conductive traces 24 .

[0025] A plurality of chips 22 are installed on the packaging substrate, and the plurality of chips 22 are divided into four groups, and the chips 22 in each group are connected in series through gold wires 23 .

[0026] A mult...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com