Contact component

A technology for contact elements and electrical wiring, which is applied in the manufacture of contacts, electrical elements, connections, etc., can solve the problems of high cost of contact elements, and achieve the effect of improving conductive transition and reliable quality

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

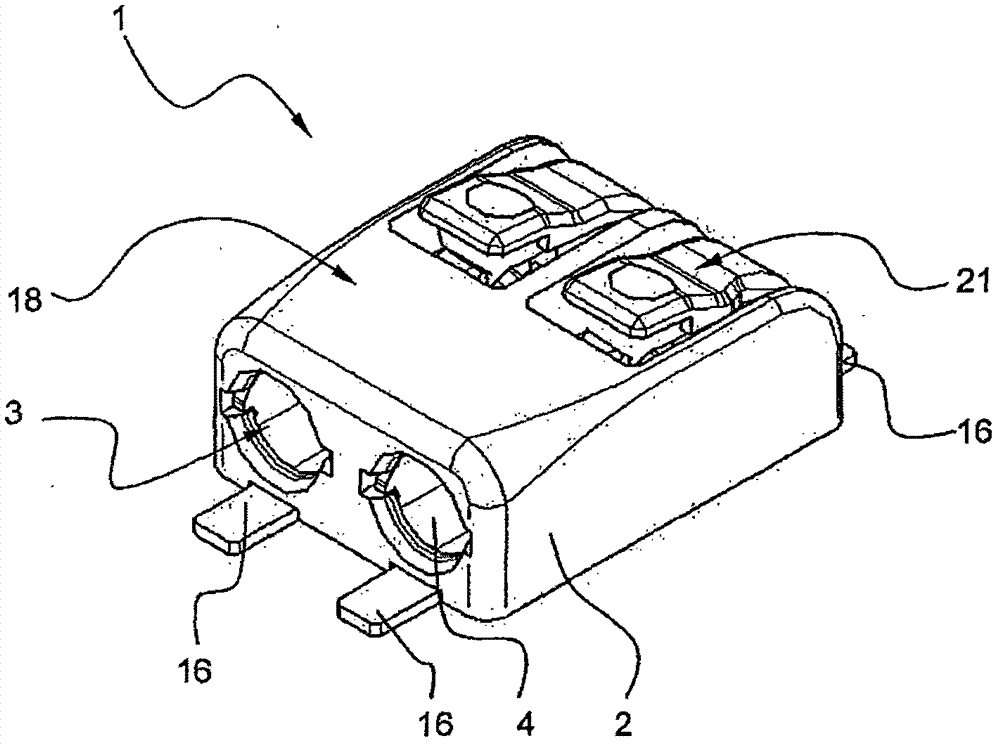

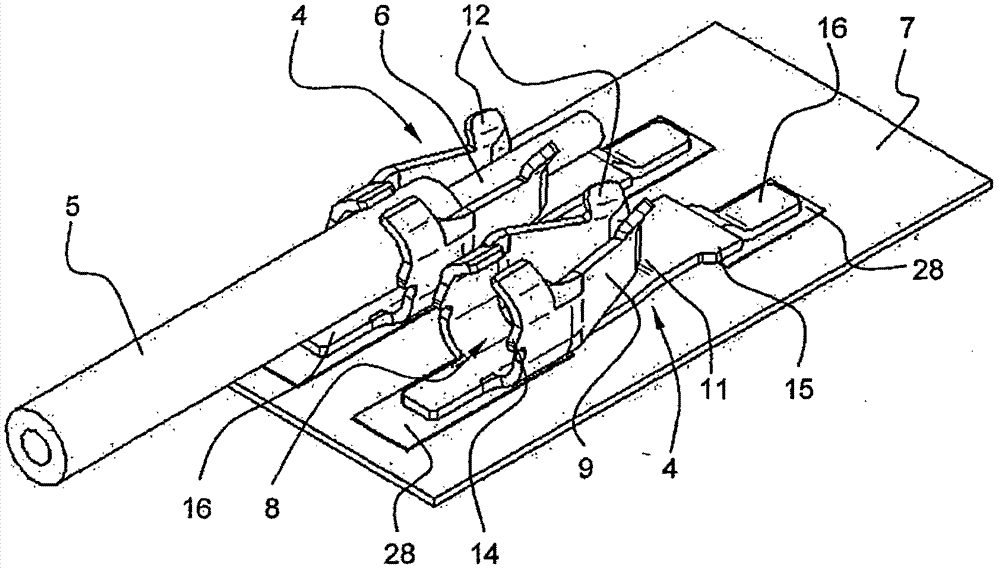

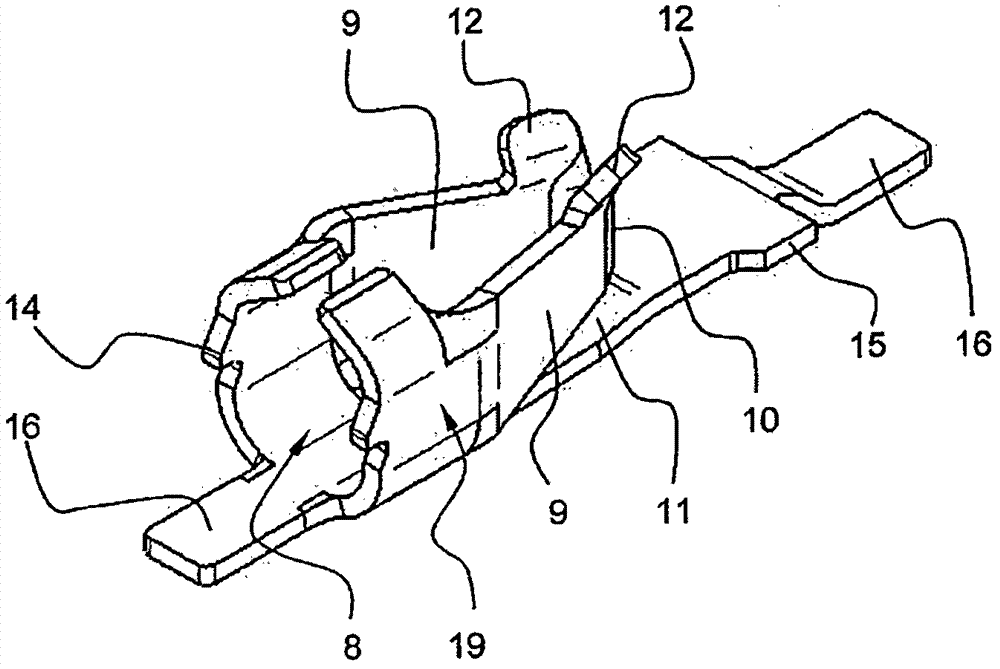

[0020] figure 1 It shows an electrical terminal 1 with an insulating material housing 2 in which metallic contact elements 4 are accommodated. The insulating material shell 2 has at least one wire lead-in hole 3 on its one end face, is used for inserting electric wire 5 ( figure 2 ). In the exemplary embodiment shown, the terminal clamp 1 is designed as a double pole, each pole having a conductor feedthrough 3 and a contact element 4 . However, the terminal clip can also have any other different number of poles.

[0021] Also from figure 1 It can be seen in the connection area 16 of the contact element 4, whose contacts make contact with the printed circuit board 7 ( figure 2 ) of the corresponding contact segment 28, such as a printed circuit. The connection area 16 is here in particular connected to the contact section 28 by a solder connection (SMD soldering), but a plug connection is also conceivable. exist figure 2 The contact element 4 fixed on the printed circ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com