Method of preparing yarn thrum cut in a certain length and spinner with a device for preparing the yarn thrum for executing said method

A technology of preparation device and textile machine, applied in the direction of piecing device, continuous winding spinning machine, spinning machine, etc., can solve problems such as damage to the yarn end, and achieve the effects of reliable energy, energy saving, and reliable longitudinal alignment

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

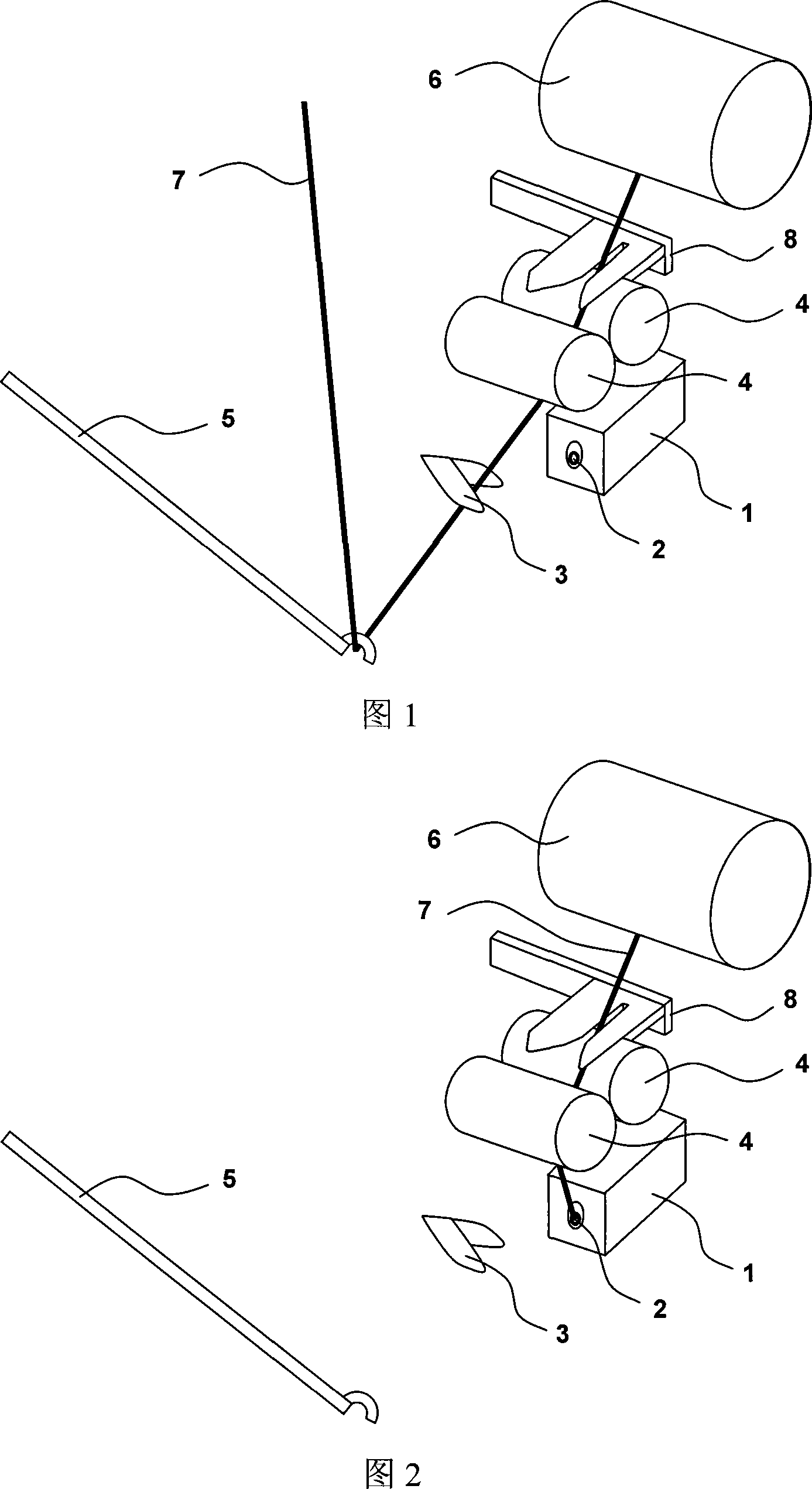

[0037] Figure 1 shows parts of a device for preparing yarn ends for subsequent joining of yarn ends to fiber material, for example in the rotor of an air spinning machine, or for joining yarn ends to another during splicing yarn head. The device has a yarn end preparation device (GEP) 1 comprising a cavity open at least towards one side, into which the yarn end is introduced via an inlet 2 after being cut to length by a cutting device 3 Inside. Here, a mechanism is assigned to the GEP1 or the yarn end, by means of which the yarn end and / or the GEP1 can be moved substantially in the axial direction of the thread introduction at least during the preparation of the yarn end.

[0038] In the embodiment shown in FIG. 1, the mechanism is a pair of feed rollers 4 provided with at least one, in particular reversible, individual drive. For example, the yarn end of the yarn 7 wound on the cross-wound bobbin is usually moved to the vicinity of the GEP1 by the grabbing device 5 after th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com