Plugging device for circuit board and server

A technology for plugging and unplugging devices and circuit boards, which is applied in the directions of servers, circuits, coupling devices, etc., can solve problems such as difficulty in realizing hot plugging and unplugging of PCI-E cards.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

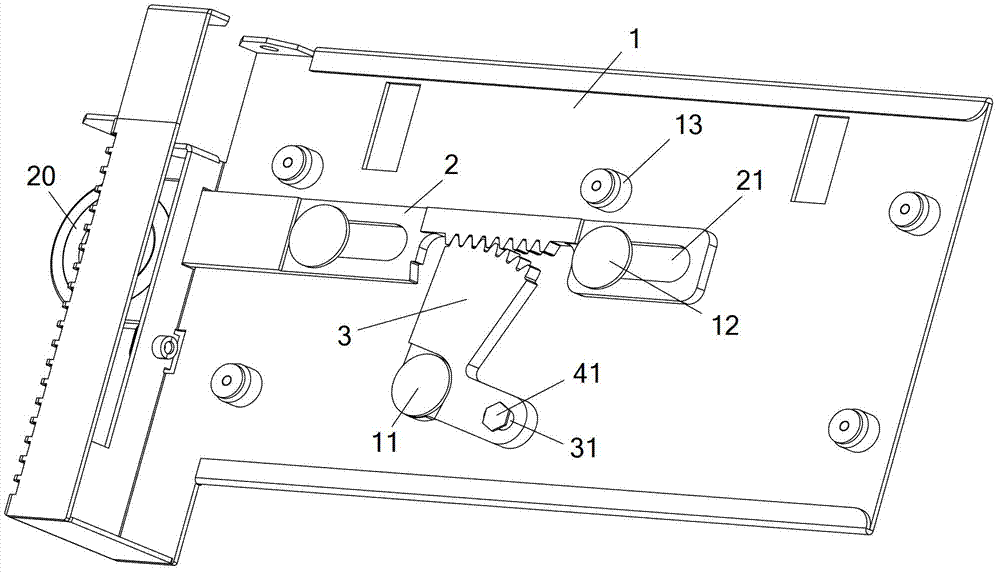

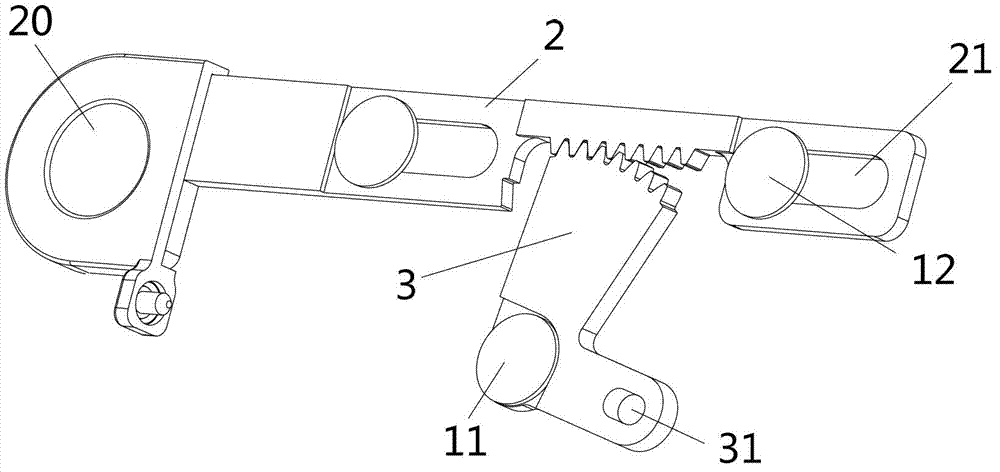

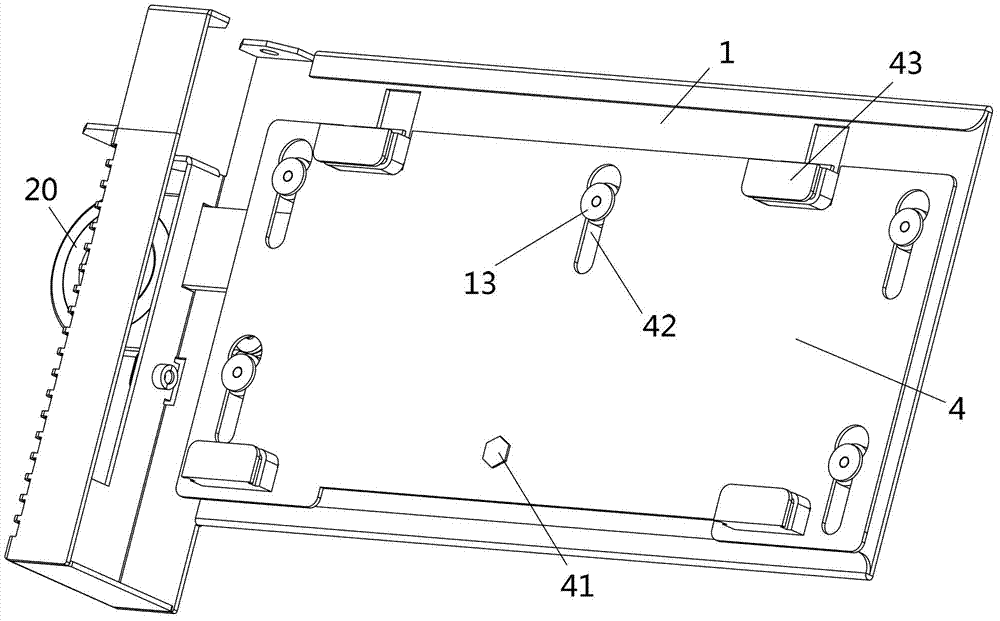

[0031] Such as figure 1 , figure 2 and image 3 As shown, the circuit board insertion and extraction device provided by the embodiment of the present invention includes a base plate 1, a pull bar 2, a rotating member 3 and a carrier plate 4, wherein the pulling bar 2 and the rotating member 3 are located between the carrier plate 4 and the base plate 3 .

[0032] The pull bar 2 is movably connected with the bottom plate 1 through a transverse guiding mechanism, and the bar body of the pull bar 2 is provided with sawtooth. One end of the pull bar 2 extends out of the board surface of the bottom plate 1 and forms a handle 20 as a handle when moving the pull bar 2 . The rotating part 3 is in the shape of a broken line, and the bending angle is preferably 90°. The rotating part 3 includes a first arm, a first rotating shaft (or hinge) 11 and a second arm. The first rotating shaft 11 is arranged at the turning point of the rotating part 3. A rotating shaft 11 is used for movab...

Embodiment 2

[0044] This embodiment is basically the same as Embodiment 1, the difference is: as Figure 7 and Figure 8 As shown, in this embodiment, the transmission mechanism includes a transmission guide groove 412 arranged on the carrier plate 4, and a first fixed pin 312 sleeved in the transmission guide groove 412, and the first fixed pin 312 is fixed on the rotating member (Fig. not shown in the second arm). Preferably, the transmission guide groove 412 extends laterally, and the length of the transmission guide groove 412 is defined as the lateral movement range of the first fixing pin 312 during the rotation of the rotating member.

[0045] When the rotating member 3 rotates, under the cooperation of the first fixed pin 312 and the longitudinal guide mechanism, the carrier plate 4 is driven to move longitudinally, and at the same time, the first fixed pin 312 also slides laterally in the transmission guide groove 412 relative to the carrier plate 4 .

[0046] It should be noted...

Embodiment 3

[0048] This embodiment is basically the same as Embodiment 2, the difference is: as Figure 9 As shown, in this embodiment, there are two rotating parts 3 , and the saw teeth at the end of the first arm of each rotating part 3 are engaged with the saw teeth on the pull bar 2 .

[0049] The pull bar 2 drives the two rotating parts 3 to rotate synchronously, and the two rotating parts 3 synchronously drive the carrier plate (not shown in the figure) to move longitudinally, that is, there are two stress points on the carrier plate, so that the carrier plate The force is more balanced and the moving process is more stable. In addition, if one of the rotating parts is damaged, the other rotating part can also independently drive the carrier plate to move longitudinally.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com