LED drive circuit

A technology of LED drive and LED light source, applied in the field of lighting, can solve the problems of high cost, easy damage, complex circuit, etc., and achieve the effect of avoiding light decay acceleration or burning out

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

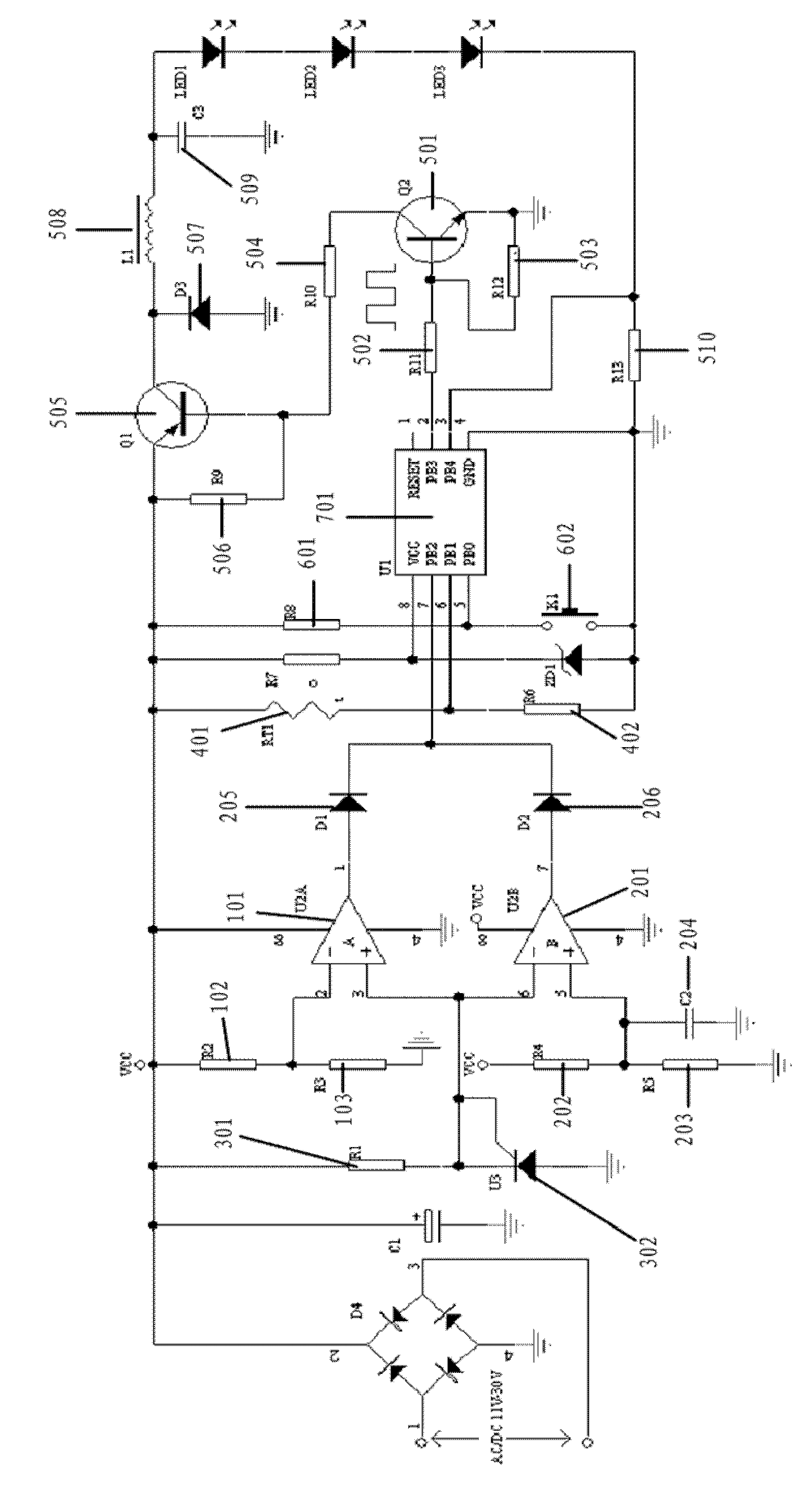

[0027] In order to make the object, technical solution and advantages of the present invention more clear, the LED driving circuit of the present invention will be further described in detail below in conjunction with the accompanying drawings and embodiments. It should be understood that the specific embodiments described here are only used to explain the present invention, not to limit the present invention.

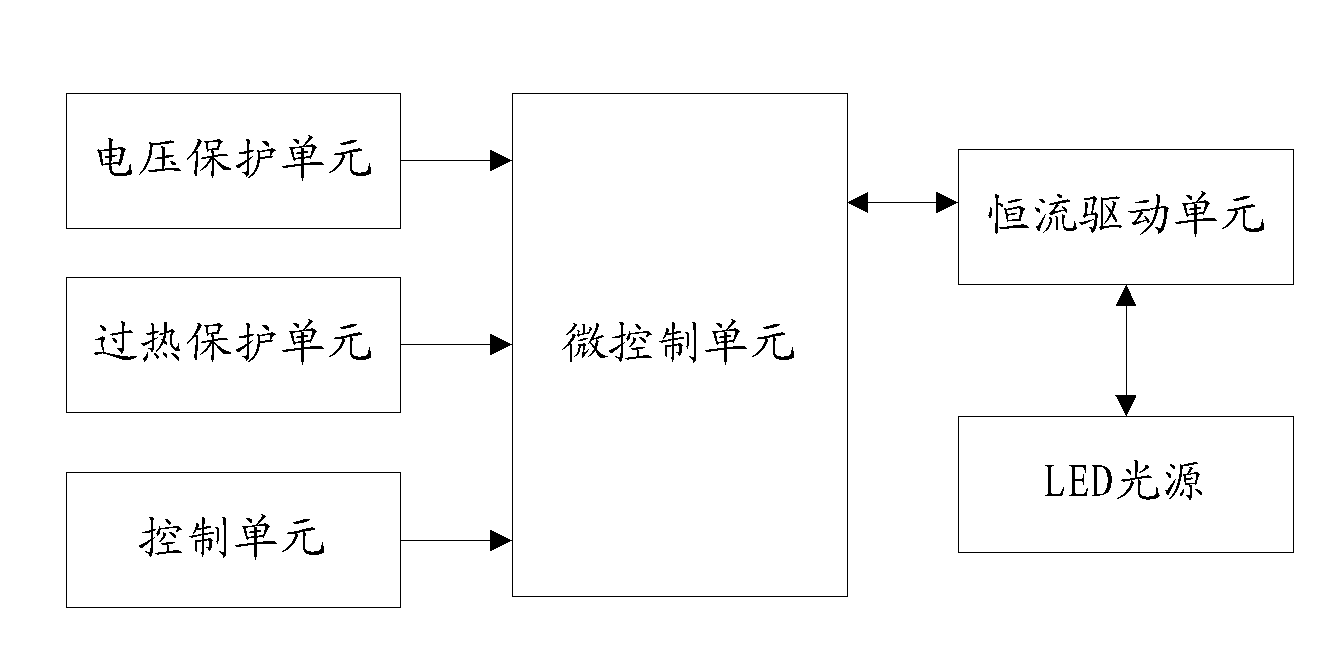

[0028] The LED driving circuit of the present invention, such as figure 1 As shown, it includes a Micro Control Unit (MCU for short), a voltage protection unit and an LED light source; when the input voltage of the LED driving circuit is between the rated minimum voltage and the rated maximum voltage, the LED light source works normally; If the rated minimum voltage is 11 volts, the rated maximum voltage is 30 volts;

[0029] The voltage protection unit includes an undervoltage protection module, an overvoltage protection module and a reference voltage stabilizing mod...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com