Coupling system between waste heat generating device and waste heat absorbing device

A coupling system and generating device technology, applied in the field of coupling systems, can solve problems such as poor contact, structural space limitations, and difficult to fix components in the central area, and achieve the effect of small assembly investment and helpful assembly

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

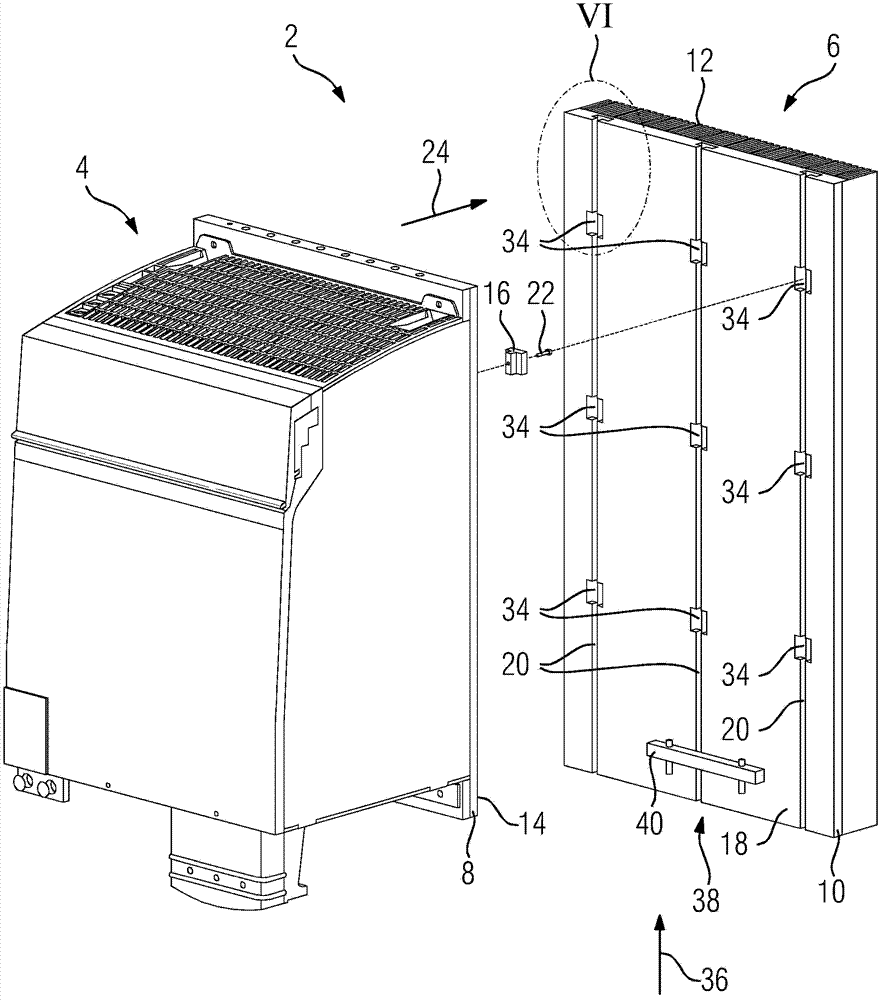

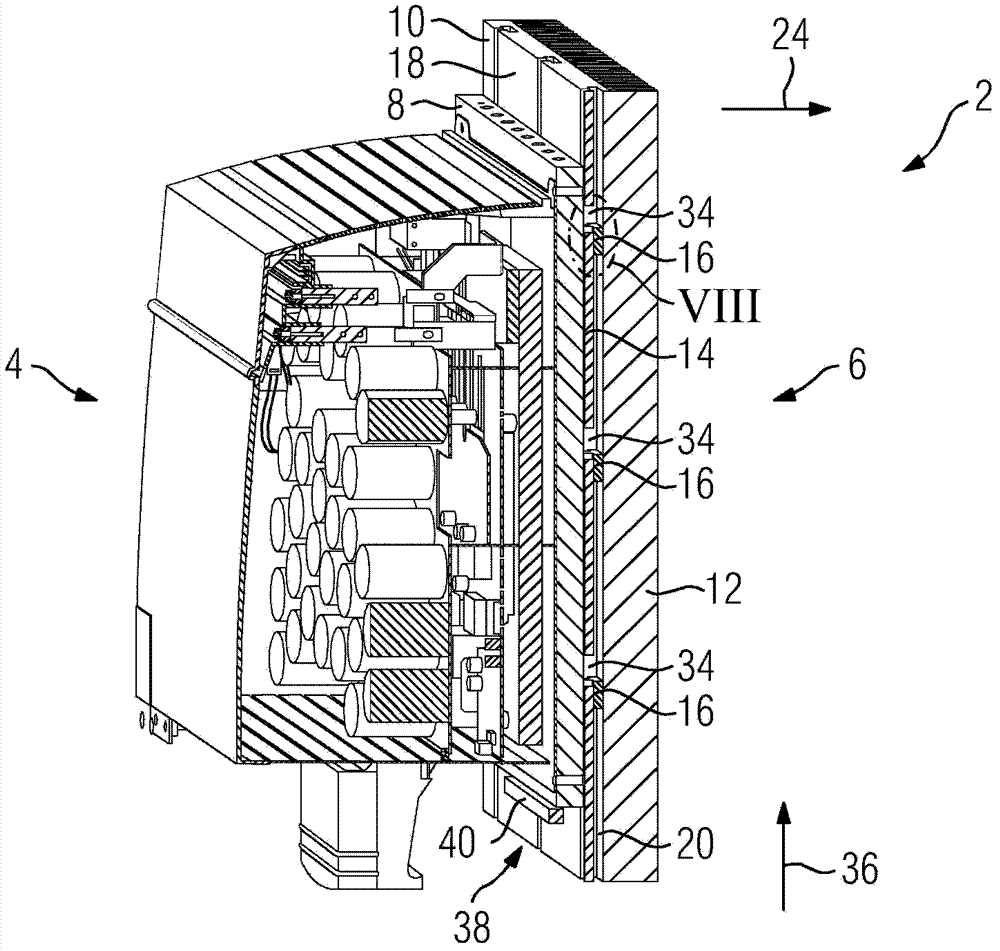

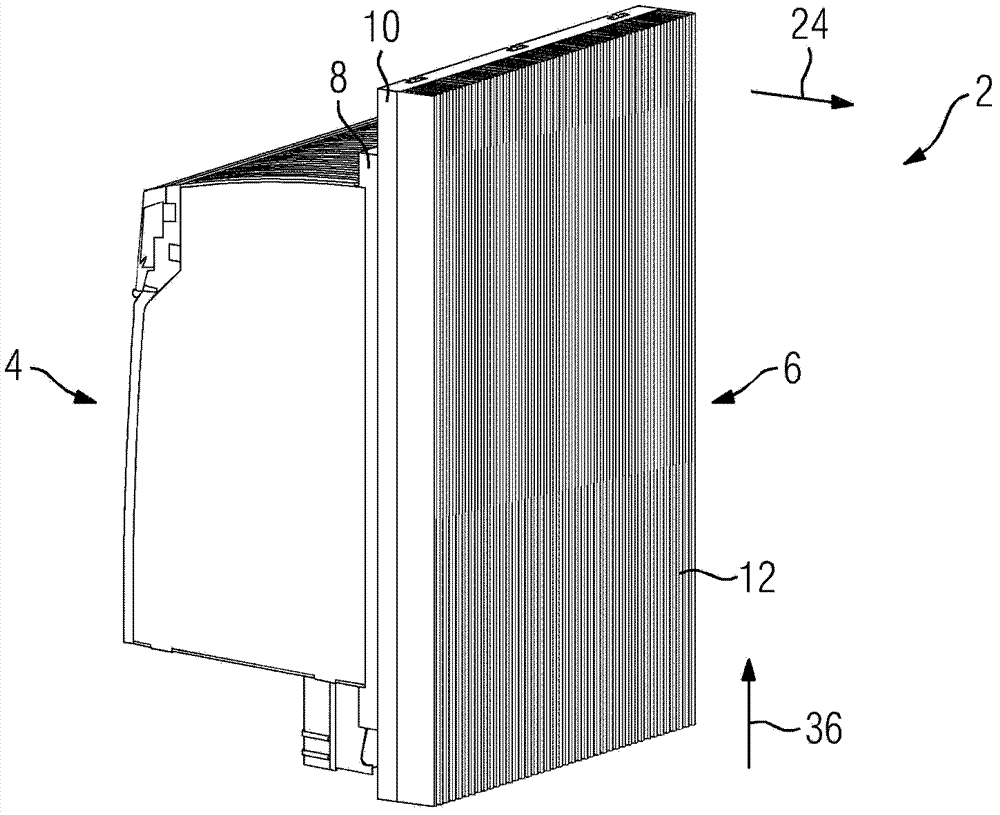

[0035] described below, in figure 1A coupling system 2 of the kind depicted in the exploded view of is used in the exemplary embodiment as a thermal interface between the converter 4 and the cooling body 6 . The converter 4 serves here as waste heat generator and has a square first contact plate 8 made of aluminum. The cooling body 6 , which is used here by way of example as waste heat absorber, likewise has a square second contact plate 10 made of aluminum. In the assembled state of the coupling system 2, in the corresponding view figure 2 and image 3 In , the two contact plates 8 , 10 are placed in parallel planes to each other for heat exchange purposes. The two contact plates 8 , 10 are thus both components of the converter 4 or heat sink 6 and part of the coupling system 2 . A plurality of groove-spring connections are provided for connecting and tensioning the two contact plates 8 , 10 , so that in the exemplary embodiment the coupling system 2 is provided by the t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com